In the world of heavy machinery, efficiency and reliability are paramount. When it comes to hydraulic systems, the performance of your equipment hinges on the quality of the hydraulic pump fitting and the hydraulic pump and cylinder kit you choose.

In this comprehensive guide, we, as experts in the field, will delve into the intricacies of hydraulic pump fittings and how to select the perfect hydraulic pump and cylinder kit. Whether you're a seasoned professional or a newcomer to the industry, this article will equip you with the knowledge needed to make informed decisions that can significantly impact your machinery's productivity.

Understanding Hydraulic Pump Fittings

Hydraulic pump fittings are the unsung heroes of hydraulic systems. They play a pivotal role in connecting various components, ensuring a seamless flow of hydraulic fluid, and ultimately determining the system's efficiency.

Let's explore the key aspects of hydraulic pump fittings:

1. Types of Hydraulic Pump Fittings

There are various types of hydraulic pump fittings, each designed for specific applications. The most common ones include:

➡️ Threaded Fittings: These fittings have threads and are ideal for connecting pipes and hoses securely. They come in different thread sizes and configurations to accommodate various hydraulic systems.

➡️ Fittings for Flanges: Flange fittings are renowned for their durability. They feature a flat, circular plate with mounting holes and are commonly used in high-pressure systems.

➡️ Quick Disconnect Fittings: These fittings allow for fast and efficient connection and disconnection, reducing downtime during maintenance or repairs.

2. Material Matters

The choice of material for your hydraulic pump fittings is crucial. Materials like stainless steel, brass, and carbon steel are commonly used due to their durability and resistance to corrosion. The selection should align with the specific requirements and conditions of your hydraulic system.

3. Proper Sizing

Selecting the right size of hydraulic pump fittings is essential. An incorrect size can lead to inefficiencies, leaks, and reduced overall system performance. Consult with a hydraulic expert or refer to manufacturer guidelines to ensure precise sizing.

The Hydraulic Pump and Cylinder Kit: A Match Made in Efficiency

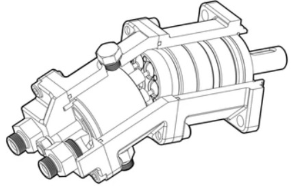

Now that we've covered the fundamentals of hydraulic pump fittings, let's shift our focus to the heart of any hydraulic system—the hydraulic pump and cylinder kit. This kit is the driving force behind the movement of heavy loads, making it a critical component for any machinery operator.

Types of Hydraulic Pumps

Hydraulic pumps come in different types, including:

➡️ Gear Pumps: Known for their simplicity and reliability, gear pumps are widely used in various applications.

➡️ Piston Pumps: These pumps are highly efficient and are often employed in heavy-duty machinery.

➡️ Vane Pumps: Vane pumps offer smooth and consistent flow, making them suitable for precision tasks.

Considerations for Cylinder Kits

When choosing a hydraulic pump and cylinder kit, several factors must be considered:

➡️ Pressure Rating: Ensure that the kit can handle the maximum pressure requirements of your hydraulic system.

➡️ Flow Rate: The flow rate of the pump should match the demands of your cylinders to prevent underperformance.

➡️ Compatibility: Confirm that the pump and cylinder kit are compatible with your machinery's specifications, including size and mounting options.

Making the Right Choice

Now that you understand the critical components of hydraulic systems, you're better equipped to make informed decisions. To ensure optimal performance and efficiency in your machinery, follow these steps:

➡️ Consult with Experts

Don't hesitate to seek advice from hydraulic experts or manufacturers. They can provide valuable insights and recommend the most suitable hydraulic pump fittings and kits for your specific needs.

➡️ Regular Maintenance

Routine maintenance is essential to keep your hydraulic system in top shape. Inspect fittings and components for signs of wear and tear, and replace them as needed to prevent costly breakdowns.

➡️ Quality Matters

Invest in high-quality hydraulic pump fittings and cylinder kits from reputable manufacturers. Cutting corners on quality can lead to compromised performance and safety issues.

Conclusion

In the world of heavy machinery, the efficiency and reliability of hydraulic systems are non-negotiable. By understanding the nuances of hydraulic pump fittings and selecting the perfect hydraulic pump and cylinder kit, you can elevate the performance of your machinery to new heights.

Note, the key to success is in the details. Make sure you choose the right fittings, materials, and components for your hydraulic system, and always prioritize quality and expert guidance.

Post time: Oct-04-2023