Hydraulic systems play a crucial role in various industries, from heavy machinery to power generation. Within these systems, the integrity of connections is paramount, and that's where hydraulic flange fittings come into play. These essential components provide reliable and leak-free connections, ensuring the smooth operation of hydraulic systems. These flange fittings adhere to different international standards including BS 2470, ISO 6164, BS_ISO 6162-2, BS_ISO 06162-2, SAE_J518, BS_ISO 12151-3, and SAE_J2244-1, ensuring top notch quality to your hydraulic system solution.

In this article, we will explore the world of hydraulic flange fittings, discussing their types, components, working principles, benefits, applications, considerations for selection, maintenance, troubleshooting, and safety precautions.

Types of Hydraulic Flange Fittings

SAE Code 61 and SAE Code 62 Flange Fittings

SAE Code 61 and SAE Code 62 flange fittings are widely used in hydraulic systems, offering different pressure ratings and applications. Code 61 fittings are typically used for lower pressure applications, while Code 62 fittings are designed for higher pressure systems.

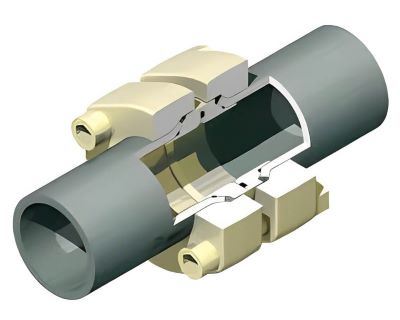

Split Flange Fittings

Split flange fittings provide a practical solution for applications that require easy installation and maintenance. They consist of two halves that can be easily bolted together, making access to the connection point simpler.

Flare Flange Fittings

Flare flange fittings are designed to withstand high-pressure environments. Their unique flare design allows for increased strength, making them ideal for demanding hydraulic applications.

Flat Face Flange Fittings

Flat face flange fittings are known for their excellent sealing capabilities. The flat surfaces of the flanges ensure a tight and secure connection, preventing fluid leakage even under high-pressure conditions.

Components of Hydraulic Flange Fittings

Hydraulic flange fittings are comprised of several key components that work together to ensure a reliable connection:

➢ Flange

The flange serves as the main connecting component in hydraulic flange fittings. It provides a stable and secure connection point between two hydraulic components or systems.

➢ O-ring Seal

The O-ring seal is a crucial component that ensures a leak-free connection. It is positioned between the flange surfaces, creating a tight seal that prevents hydraulic fluid from escaping.

➢ Bolts and Nuts

Bolts and nuts are used to secure the flange and maintain the connection integrity. Proper tightening of bolts and nuts is essential to ensure a secure and leak-free hydraulic system.

➢ Flange Pad

The flange pad acts as a buffer between the flange and the surface it connects to. It helps distribute the pressure evenly, reducing the risk of damage or leaks.

Working Principle of Hydraulic Flange Fittings

Hydraulic flange fittings operate based on a simple yet effective principle:

➢ Flange Connection for Leak-Free Hydraulic Systems

The primary purpose of hydraulic flange fittings is to create a reliable and leak-free connection between hydraulic components or systems. The flanges, O-ring seals, bolts, and nuts work together to achieve this by providing a tight and secure connection.

➢ Role of O-ring Seal in Preventing Fluid Leakage

The O-ring seal plays a critical role in preventing fluid leakage. When the flanges are bolted together, the O-ring seal is compressed, creating a seal that prevents hydraulic fluid from escaping. This ensures a leak-free hydraulic system.

➢ Tightening Bolts and Nuts for Secure Connection

Properly tightening the bolts and nuts is crucial for maintaining a secure connection. It ensures that the flanges are held together tightly, preventing any movement or separation that could lead to leaks or system failure.

Benefits of Hydraulic Flange Fittings

Hydraulic flange fittings offer several benefits that make them highly advantageous in hydraulic systems:

➢ High-Pressure Capabilities for Demanding Applications

Hydraulic flange fittings are designed to withstand high-pressure environments. They provide a robust connection that can handle the demanding conditions commonly found in hydraulic systems.

➢ Easy Installation and Removal

The design of hydraulic flange fittings allows for easy installation and removal, making maintenance and repairs more efficient. The split flange fittings, in particular, offer convenience by simplifying access to the connection point.

➢ Reliable and Leak-Free Connections

By utilizing flanges and O-ring seals, hydraulic flange fittings provide reliable and leak-free connections. This ensures the integrity of the hydraulic system, minimizing the risk of fluid leakage and potential damage.

➢ Enhanced Safety and Durability

The secure and leak-free connections offered by hydraulic flange fittings enhance the overall safety of hydraulic systems. They help prevent accidents, equipment damage, and environmental hazards. Additionally, the robust construction of flange fittings ensures their durability, even in challenging operating conditions.

Applications of Hydraulic Flange Fittings

Hydraulic flange fittings find applications in various industries and sectors:

➢ Industrial Machinery and Equipment

Hydraulic systems are widely used in industrial machinery and equipment. Hydraulic flange fittings provide reliable connections in applications such as manufacturing equipment, hydraulic presses, and material handling machinery.

➢ Hydraulic Systems in Construction and Mining

Construction and mining operations rely heavily on hydraulic systems to power heavy machinery and perform demanding tasks. Hydraulic flange fittings ensure the proper functioning of these systems, enabling reliable performance in tough conditions.

➢ Offshore and Marine Applications

Hydraulic systems are essential in offshore and marine environments, where they power various equipment and machinery. Hydraulic systems used in offshore drilling rigs, ships, and marine vessels benefit from the reliable connections provided by hydraulic flange fittings.

➢ Power Generation and Oil Refining Industries

Power generation facilities and oil refineries utilize hydraulic systems for control and operation purposes. Hydraulic flange fittings ensure the efficient and reliable functioning of critical equipment and machinery in these industries.

Considerations for Choosing Hydraulic Flange Fittings

When selecting hydraulic flange fittings, several factors should be taken into account:

➢ Pressure and Temperature Requirements

Consider the operating pressure and temperature of your hydraulic system to ensure that the chosen flange fittings can handle the specific conditions without compromising performance or safety.

➢ Compatibility with Hydraulic Fluids

It's essential to select hydraulic flange fittings that are compatible with the hydraulic fluids used in your system. Compatibility ensures optimal performance and prevents issues such as fluid degradation or seal damage.

➢ Flange Size and Connection Type

Determine the appropriate flange size and connection type based on the requirements of your hydraulic system. Consider factors such as flow rate, system layout, and compatibility with existing components.

➢ Material Selection Based on Application

The material used in hydraulic flange fittings can vary depending on the application and environmental conditions. Consider factors such as corrosion resistance, durability, and suitability for the specific application to choose the right material.

Maintenance and Troubleshooting

Proper maintenance and troubleshooting practices help ensure the longevity and reliable performance of hydraulic flange fittings:

➢ Regular Inspection for Signs of Wear or Damage

Periodically inspect hydraulic flange fittings for signs of wear, damage, or leakage. Address any issues promptly to prevent further damage or system failure.

➢ Proper Torque Tightening of Bolts and Nuts

Regularly check the tightness of bolts and nuts in hydraulic flange fittings and ensure they are torqued to the manufacturer's specifications. Proper torque tightening ensures a secure connection and minimizes the risk of leaks.

➢ Replacing O-ring Seals When Necessary

O-ring seals can wear out over time, leading to potential fluid leakage. Replace worn or damaged seals promptly to maintain a reliable and leak-free hydraulic system.

Troubleshooting Common Issues and Solutions

Familiarize yourself with common issues that may arise with hydraulic flange fittings, such as leaks or improper sealing. Learn troubleshooting techniques and solutions to address these issues effectively.

Safety Precautions for Working with Hydraulic Flange Fittings

Working with hydraulic flange fittings requires adherence to proper safety protocols:

➢ Proper Training and Knowledge of Installation Procedures

Ensure that individuals working with hydraulic flange fittings have the necessary training and knowledge of proper installation procedures. This minimizes the risk of accidents and ensures correct assembly.

➢ Wearing Personal Protective Equipment (PPE)

When working with hydraulic flange fittings, it's important to wear appropriate personal protective equipment, including gloves, safety glasses, and any other necessary gear to protect against potential hazards.

➢ Following Manufacturer's Guidelines and Specifications

Always follow the manufacturer's guidelines and specifications when installing, maintaining, or troubleshooting hydraulic flange fittings. Adhering to these instructions ensures safety and proper functioning.

➢ Regular System Checks and Maintenance

Implement a regular maintenance schedule for hydraulic systems that includes inspections, fluid checks, and other maintenance tasks. Regular system checks help identify and address potential issues before they escalate.

Conclusion

Hydraulic flange fittings are integral components in hydraulic systems, providing reliable and leak-free connections for a wide range of applications. By understanding the types, components, working principles, benefits, applications, selection considerations, maintenance, troubleshooting, and safety precautions associated with hydraulic flange fittings, you can optimize the performance and longevity of your hydraulic system.

Remember, proper installation, maintenance, and adherence to safety guidelines are crucial for ensuring the safe and efficient operation of hydraulic flange fittings. By utilizing the right flange fittings for your specific needs, you can enjoy the benefits of reliable connections, leak-free performance, and enhanced safety in your hydraulic systems.

Post time: Jul-14-2023