Hydraulic systems are vital components in various industries, ranging from construction and agriculture to manufacturing and transportation. At the heart of these systems lies the ingenious quick connect hydraulic hose fittings, which play a crucial role in ensuring seamless fluid transmission and system efficiency. In this article, we will delve into the intricacies of quick connect hydraulic hose fittings, exploring their types, selection factors, installation procedures, and maintenance practices, while also addressing common challenges and best practices for maximizing their lifespan.

The Basics of Quick Connect Hydraulic Hose Fittings

Hydraulic systems harness the power of fluid to transmit force and energy, making them versatile and efficient. Central to these systems are hydraulic hose fittings, which enable the secure connection between hoses, pipes, and other hydraulic components. Quick connect hydraulic hose fittings, in particular, have gained popularity due to their efficiency and ease of use. By eliminating the need for thread engagement, these fittings enable rapid and hassle-free connections, saving valuable time in critical operations.

Types of Quick Connect Hydraulic Hose Fittings

Threaded Quick Connect Fittings

Threaded quick connect fittings employ threaded connections to secure hoses and pipes. These fittings utilize male and female threads to create a reliable connection, making them suitable for applications with high vibration or movement. Their robust construction ensures long-lasting performance, and they find extensive use in heavy machinery, hydraulic tools, and industrial applications.

Push-to-Connect Quick Connect Fittings

Push-to-connect quick connect fittings feature a simple yet effective design that allows users to connect hoses effortlessly. By pushing the hose into the fitting, a series of internal components engage, creating a secure connection. These fittings are popular in pneumatic and low-pressure hydraulic applications, providing reliable connections without the need for tools or additional components.

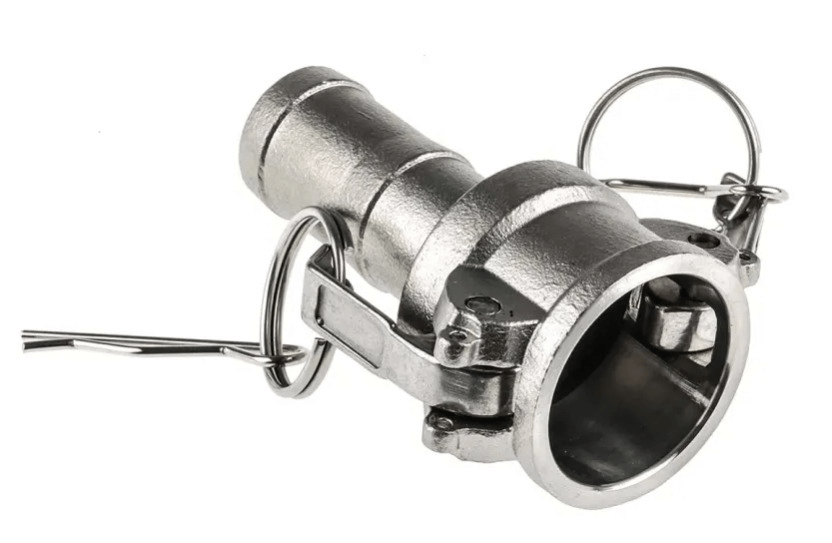

Cam and Groove Quick Connect Fittings

Cam and groove quick connect fittings, also known as camlock couplings, offer rapid and secure connections through a system of grooves and levers. These fittings consist of a male "cam" adapter and a female "groove" adapter, which interlock with each other when connected. Cam and groove fittings excel in applications requiring frequent connections and disconnections, such as fluid transfer and irrigation systems.

Factors to Consider When Choosing Quick Connect Hydraulic Hose Fittings

Selecting the right quick connect hydraulic hose fittings is crucial to ensure optimal performance and system longevity. Several key factors should be considered during the selection process:

➢ Operating Pressure and Temperature Range

Quick connect fittings must be capable of withstanding the operating pressure and temperature conditions of the hydraulic system. Choosing fittings with appropriate pressure and temperature ratings ensures compatibility and minimizes the risk of leaks or failures.

➢ Compatibility with Hose Material

Different hydraulic hoses are constructed from various materials, such as rubber, thermoplastic, or metal. It is essential to select quick connect fittings that are compatible with the specific hose material to ensure a secure and leak-free connection.

➢ Connection Method and Ease of Use

The connection method of quick connect fittings can vary, and it is important to consider the convenience and ease of use for the specific application. Factors such as accessibility, connection speed, and ergonomics play a role in determining the most suitable fitting design.

Installation and Maintenance of Quick Connect Hydraulic Hose Fittings

Proper installation and maintenance procedures are critical to the performance and longevity of quick connect hydraulic hose fittings. Adhering to industry best practices ensures a secure and leak-free connection, minimizing downtime and maximizing efficiency.

➢ Proper Installation Procedures:

Installing quick connect fittings involves several essential steps to guarantee a reliable connection:

➢ Preparing Hose and Fitting Surfaces:

Ensure that both the hose and fitting surfaces are clean and free from debris or contaminants. This promotes a proper seal and prevents potential leaks.

➢ Step-by-Step Installation Instructions:

Follow the manufacturer's guidelines for your specific type of quick connect fitting, ensuring that all components are correctly aligned and engaged.

➢ Routine Maintenance Practices:

It's crucial to perform routine maintenance to see possible problems early and fix them. Implementing the following maintenance practices will help optimize the performance of quick connect hydraulic hose fittings:

➢ Inspections and Leak Detection:

Routinely inspect fittings for signs of wear, corrosion, or damage. Perform leak tests using appropriate methods such as pressure testing or visual inspections.

➢ Cleaning and Lubrication Guidelines:

Clean fittings and remove any built-up dirt or debris. Apply suitable lubricants as recommended by the manufacturer to ensure smooth operation and minimize friction.

Common Challenges and Troubleshooting Tips

Despite their reliability, quick connect hydraulic hose fittings can face certain challenges. Understanding common issues and troubleshooting techniques can help resolve problems efficiently.

➢ Leakage and Dripping Issues:

Leakage or dripping from quick connect fittings can occur due to various reasons, such as:

➢ Identifying Potential Causes:

Inspect fittings for damaged seals, worn components, or improper installation. Check for excessive pressure or temperature that may exceed the fitting's rating.

➢ Troubleshooting Techniques:

Replace damaged seals or components, ensure proper alignment and engagement, and verify that the fitting is suitable for the system's pressure and temperature requirements.

➢ Flow Restriction and Pressure Drop:

Flow restrictions or pressure drops can hinder system performance and efficiency. Addressing these issues requires:

➢ Understanding Flow Restrictions in Fittings:

Evaluate the internal design of the fitting for any obstructions or restrictions that may impede fluid flow.

➢ Troubleshooting Methods to Address Pressure Drop:

Clean or replace clogged fittings, optimize the system layout to minimize pressure drop, and ensure proper sizing of fittings for the required flow rate.

Best Practices for Extending the Lifespan of Quick Connect Hydraulic Hose Fittings

To maximize the lifespan of quick connect hydraulic hose fittings and enhance overall system reliability, adopting best practices is essential.

➢ Proper Handling and Storage:

Following these tips will help maintain the integrity of the fittings during handling and storage:

Note: Avoid dropping or mishandling fittings, as it can cause damage. Store fittings in a clean and protected environment to prevent contamination or corrosion.

➢ Guidelines for Storage Conditions:

Store fittings in a dry and well-ventilated area, away from direct sunlight and extreme temperatures. Protect fittings from exposure to chemicals or substances that may degrade their performance.

➢ Preventive Maintenance Strategies:

Implementing preventive maintenance practices can significantly extend the lifespan of quick connect fittings:

➢ Regular Inspections and Replacement Schedules:

Establish a schedule for routine inspections, including visual checks for wear, corrosion, or damage. Replace fittings or components as necessary to prevent failures.

➢ Implementing Preventive Maintenance Programs:

Develop a comprehensive maintenance program that includes regular cleaning, lubrication, and proactive replacements based on recommended service intervals.

Conclusion

Quick connect hydraulic hose fittings are indispensable components in hydraulic systems, offering efficient and reliable connections. Understanding the different types of quick connect fittings, selecting the appropriate fittings based on specific factors, following proper installation and maintenance procedures, and addressing common challenges are crucial to ensure optimal performance and longevity. By adhering to best practices and maintaining these fittings, industries can enhance productivity, minimize downtime, and achieve efficient fluid transmission within their hydraulic systems.

As technology evolves, quick connect hydraulic hose fittings continue to play a vital role in simplifying fluid connections and streamlining operations. Their convenience, reliability, and compatibility make them an invaluable asset across diverse industries. Embracing these fittings not only enhances efficiency but also ensures the smooth functioning of hydraulic systems, contributing to overall productivity and success.

Remember to consult with industry professionals or manufacturers for specific guidance and recommendations pertaining to your hydraulic system requirements.

Post time: Jun-23-2023