In the world of hydraulic systems, there exists a silent powerhouse known as the Primary Mover Hydraulic Pump. This unassuming component is at the heart of hydraulic machinery, driving the force behind countless applications in various industries.

In this comprehensive guide, we will delve deep into the primary mover hydraulic pump, its primary function in a hydraulic system, and everything you need to know about this indispensable technology.

The Role of the Primary Mover Hydraulic Pump

1. Powering Hydraulic Systems

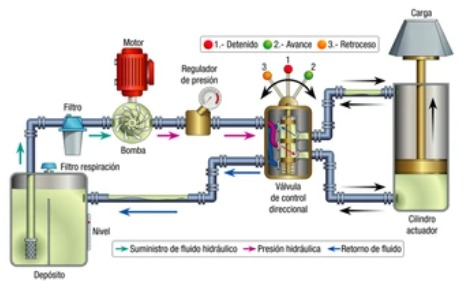

At the core of any hydraulic system, you’ll find the primary mover hydraulic pump, often referred to simply as the hydraulic pump. Converting mechanical energy into hydraulic energy is its main purpose. When activated, it draws in hydraulic fluid and pressurizes it, creating the force necessary to drive various hydraulic components like cylinders and motors.

2. Maintaining Flow and Pressure

A hydraulic system’s efficiency depends on maintaining a consistent flow of hydraulic fluid at the right pressure. The primary mover hydraulic pump plays a pivotal role in regulating this flow and pressure. It ensures that the hydraulic system operates smoothly, providing the force required for tasks ranging from heavy machinery operation to precision control in aircraft.

The Types of Hydraulic Pumps

Now that we understand the primary function of the primary mover hydraulic pump, let’s explore the various types of hydraulic pumps:

1. Gear Pumps

One of the most popular kinds of hydraulic pumps is the gear pump. They use meshing gears to pump hydraulic fluid. These pumps are known for their simplicity, reliability, and affordability. However, they may not be suitable for high-pressure applications.

2. Vane Pumps

Vane pumps operate using a rotating vane inside a circular chamber. They provide a fair compromise between effectiveness and price. Vane pumps are often used in medium-pressure hydraulic systems.

3. Piston Pumps

Piston pumps are the workhorses of high-pressure hydraulic systems. They use pistons to push hydraulic fluid, making them ideal for applications where extreme pressure is required.

4. Axial Piston Pumps

Axial piston pumps are a specialized type of piston pump known for their efficiency and compact design. They are often used in mobile hydraulic systems, such as those found in construction equipment.

Frequently Asked Questions

Q: How does the primary mover hydraulic pump generate pressure in a hydraulic system?

➡ The pump generates pressure by using mechanical energy to move hydraulic fluid through a system of chambers and valves, ultimately creating the force needed for various hydraulic operations.

Q: Can the type of hydraulic pump affect the efficiency of a hydraulic system?

➡ Absolutely. The choice of pump type can significantly impact the efficiency and performance of a hydraulic system. Factors like pressure requirements, flow rate, and system size must be considered when selecting a pump.

Q: Are there maintenance considerations for hydraulic pumps?

➡ Yes, regular maintenance is crucial to ensure the longevity and efficiency of hydraulic pumps. This involves checking for leaks, maintaining fluid levels, and replacing worn-out parts.

Q: Can hydraulic pumps be used in mobile applications?

➡ Yes, hydraulic pumps are commonly used in mobile applications, especially in construction and agricultural machinery, where the need for precise control and high force is essential.

Q: What innovations are on the horizon for hydraulic pump technology?

➡ The hydraulic industry is continually evolving. Innovations in pump design aim to improve efficiency, reduce energy consumption, and enhance overall system performance.

Q: How can I choose the right hydraulic pump for my specific application?

➡ Selecting the right hydraulic pump involves considering factors like flow rate, pressure requirements, and the nature of the application. It’s advisable to consult with hydraulic system experts to make an informed choice.

Conclusion

The primary mover hydraulic pump is the unsung hero of hydraulic systems, providing the power needed to move heavy machinery, control precision equipment, and drive countless industrial processes. Understanding its primary function and the different types available is essential for anyone working with hydraulic technology.

As you embark on your hydraulic journey, remember that the primary mover hydraulic pump is at the core of it all, channeling mechanical energy into hydraulic force with precision and reliability.

Post time: Oct-13-2023