When it comes to the seamless operation of industrial systems, precision and standardization play a pivotal role. In the complex world of valve automation, where valves control the flow of fluids and gasses in various industries, the ISO 5211 Standard stands as a beacon of consistency and reliability. This article delves deep into the ISO 5211 Standard, unraveling its historical origins, key components, benefits, and real-world applications.

Historical Perspective

The ISO 5211 Standard has a rich history that dates back to its initial development. This standard, which focuses on the mounting and actuation of industrial valves, has undergone significant evolution over the years. It all began with a need for standardization in valve automation, especially for multi-turn and quarter-turn actuators. Key milestones in its development include revisions that accommodated advances in technology and changes in industry requirements. Today, ISO 5211 is globally recognized and used across diverse industrial sectors.

What is ISO 5211 standard?

Before we delve deeper into ISO 5211, it’s essential to understand the International Organization for Standardization (ISO) itself. ISO is a non-governmental entity that develops and publishes international standards to ensure the quality, safety, and efficiency of products, services, and systems. ISO 5211 is just one of the many standards established by this organization, emphasizing its significance in the world of industrial standardization.

ISO 5211 in Valve Automation

Valve automation is the process of controlling valve operations using various actuators, including electric, pneumatic, and hydraulic drives. ISO 5211 acts as the bridge between the valve and the actuator. It provides a standardized interface that ensures compatibility and facilitates efficient valve actuation, a critical element in industries such as oil and gas, petrochemicals, water treatment, and more.

“What Is The Difference Between SAE And NPT? A Comprehensive Comparison“

Key Components of ISO 5211

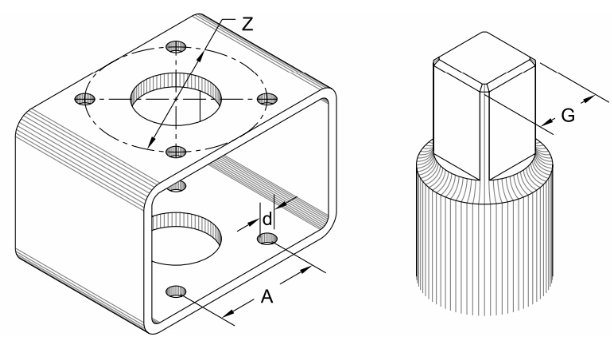

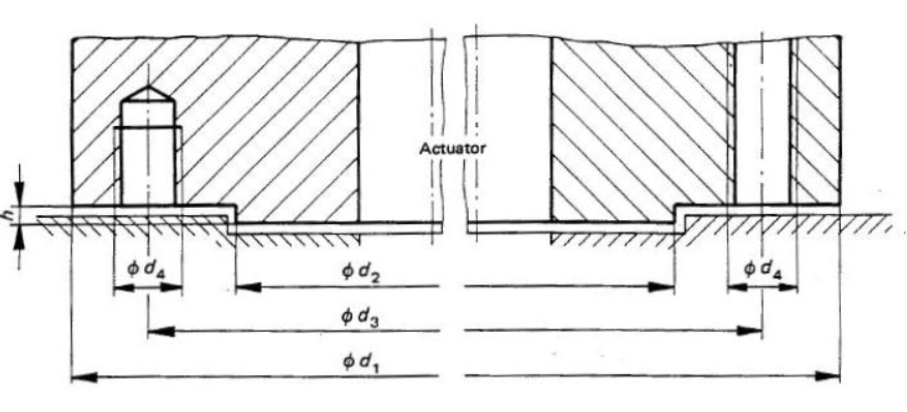

At its core, ISO 5211 defines a standardized interface that ensures compatibility between the valve and actuator. It specifies the dimensions and tolerances for valve mounting, effectively creating a uniform pattern. This means that actuators, regardless of the manufacturer, can be seamlessly attached to ISO 5211-compliant valves.

Standardized Mounting Dimensions

ISO 5211′s standardized mounting dimensions are crucial. The dimensions are designed to ensure that actuators fit perfectly onto the valve without the need for custom adaptations. This consistency in mounting patterns has a significant impact on interchangeability and ease of maintenance. In practical terms, it allows actuators to be swapped out quickly, minimizing downtime and reducing the need for specialized tools and skills.

Drive Types in ISO 5211

The standard caters to various drive types, including electric, pneumatic, and hydraulic drives. Each drive type is compatible with ISO 5211, offering flexibility for industries with varying needs. Whether it’s precise electric control, robust pneumatic actuation, or high-pressure hydraulic operation, ISO 5211 ensures that the interface is consistent and reliable.

Valve Actuation and ISO 5211

ISO 5211 simplifies the valve actuation process. It’s all about making the attachment of actuators to valves as straightforward as possible. Actuators can be easily connected to ISO 5211-compliant valves, ensuring proper alignment and secure attachment. This standardization streamlines the valve actuation process and reduces the risk of errors, improving control accuracy and overall system performance.

“SAE J1926: Navigating The World Of Hydraulic Connections“

Compliance and Certification

Ensuring compliance with ISO 5211 is essential for both manufacturers and end-users. ISO 5211 certification ensures that a product meets the required standards. It’s a quality assurance measure that assures the product’s reliability and compatibility within the ISO 5211 framework. It’s essential for industries to verify compliance, as it guarantees that the products will function as expected.

Benefits of ISO 5211 Standard

➡ ISO 5211 offers several advantages. First and foremost, it enhances interoperability and interchangeability. As mentioned, actuators from different manufacturers can be used interchangeably with ISO 5211-compliant valves. This makes it easier for industries to maintain their systems and reduces the dependency on a single manufacturer.

➡ The standardized interface also streamlines maintenance processes, leading to reduced downtime. When actuators and valves are easily interchangeable, maintenance becomes more efficient. This reduces costs and ensures that systems are up and running as quickly as possible.

➡ Moreover, ISO 5211-compliant systems tend to be more reliable. The standardized interface reduces the risk of misalignment and errors during installation. This results in improved safety and performance, especially in industries where precision control is crucial, such as the chemical and pharmaceutical sectors.

Challenges and Considerations

While ISO 5211 offers numerous benefits, there are some challenges to consider. One common issue is compatibility with legacy systems. Older systems may not be ISO 5211-compliant, leading to the need for adapters or custom modifications. In some cases, this can be a hurdle in the path toward full ISO 5211 standardization.

Ensuring the correct selection of actuators and valves is also crucial. Not all actuators are compatible with ISO 5211, and selecting the wrong one can result in costly modifications or replacements. Proper training and awareness are necessary to make the right choices.

Global Adoption and Impacts

ISO 5211 is not limited to a specific region or industry. Its global adoption has significant impacts. Economically, it reduces costs associated with maintenance and downtime. Safety-wise, it ensures precise control in critical sectors, minimizing risks. The standard also emphasizes the importance of international cooperation in setting and maintaining industry standards.

Conclusion

The ISO 5211 Standard plays a pivotal role in ensuring the compatibility and reliability of valve automation systems. Its historical development, standardized mounting dimensions, and global impact make it a cornerstone of industrial standardization. As industries continue to evolve and demand more advanced control systems, ISO 5211 is likely to adapt and remain a critical component in valve automation, enhancing performance, reducing costs, and improving safety.

Post time: Nov-15-2023