When it comes to the world of fittings and threads, there’s a significant buzz around SAE and NPT. These acronyms, often encountered in various mechanical and plumbing contexts, denote different types of threading standards. Understanding the difference between SAE (Society of Automotive Engineers) and NPT (National Pipe Taper) threads is vital for anyone working with systems that require secure connections.

In this article, we’ll delve into the details of these threading standards, explore their compatibility, and demystify their significance.

Understanding SAE and NPT Threads

What Does SAE Stand For in Pipe Thread?

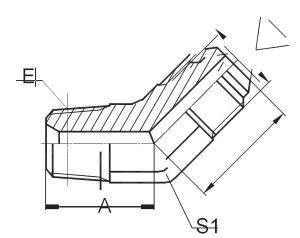

45° BSPT Male / SAE Male 90° Cone | Automotive & Hydraulic Connections

SAE stands for the Society of Automotive Engineers, an organization that sets standards for various aspects of engineering, including threads used in hydraulic and mechanical systems. In the context of pipe threading, SAE threads follow specific guidelines to ensure compatibility and functionality across different applications.

Key Features of SAE Threads

SAE threads are known for their fine and uniform threads, making them suitable for applications involving high pressures. These threads are often used in hydraulic systems, where maintaining leak-free connections is crucial. They are designed to withstand stress, ensuring reliable performance in demanding environments.

The Essence of National Pipe Taper Threads

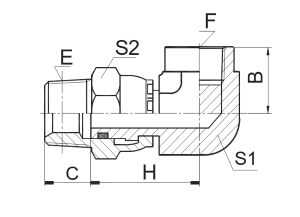

90° NPT Swivel Male / NPT Female Connection | Durable Steel

NPT, or National Pipe Taper, threads are commonly used in plumbing and industrial applications. Unlike SAE threads, NPT threads have a taper, meaning they get narrower towards the end. This taper creates a tight seal when the threads are joined, making NPT threads suitable for applications where leakage prevention is essential.

NPT Thread Characteristics

NPT threads are known for their versatility and ease of installation. Their tapered design enables a secure connection even in environments with temperature variations. The threads provide a mechanical lock, further enhancing their reliability in different settings.

Is SAE Compatible with NPT?

The compatibility between SAE and NPT threads is a common query, especially when dealing with systems that require both types of connections. While these threads have different designs, they are not inherently compatible due to structural differences.

Differences Between SAE and NPT Threads

Structural Variations

One of the primary differences between SAE and NPT threads lies in their structure. SAE threads are finer and more uniform, while NPT threads have a tapered design. This structural contrast affects their application suitability and compatibility.

Application Diversity

SAE threads are often found in hydraulic systems, where precision and leak prevention are paramount. NPT threads, on the other hand, excel in plumbing and general industrial applications due to their sealing capabilities. Understanding the application context is crucial when selecting the appropriate thread type.

Navigating the Practical Implications

Considerations for Plumbing

When it comes to plumbing, NPT threads shine. Their taper and mechanical locking mechanism make them ideal for preventing leaks in water and gas pipes. NPT threads accommodate thermal expansion and contraction, maintaining a secure connection even in varying temperatures.

Automotive and Industrial Applications

In automotive and industrial settings, SAE threads find their niche. The fine threading and uniformity of SAE threads ensure tight connections in hydraulic systems, preventing fluid leakage even under high pressures.

Pros and Cons of SAE and NPT Threads

SAE Thread Advantages and Disadvantages

SAE threads offer precise connections suitable for high-pressure applications. However, their fine threading can be challenging to work with, requiring careful handling during installation. Additionally, SAE threads may not be the best choice for applications involving temperature variations.

NPT Thread Pros and Cons

NPT threads excel in preventing leaks and are relatively easy to install. Their tapered design allows for secure connections, but they might not be suitable for applications where high pressures are involved.

Common Misconceptions

Myth Debunked: Interchangeability

One common misconception is that SAE and NPT threads can be interchanged. This is not true due to their structural differences. Attempting to combine these threads could lead to leaks and compromised connections.

Factors to Consider When Choosing

Choosing between SAE and NPT threads depends on the specific requirements of your project. Consider factors such as pressure, temperature variations, and the nature of the fluid being transported. Consulting with experts in the field can help you make an informed decision.

FAQs

Q 1: Can SAE and NPT Threads Be Interchanged?

No, SAE and NPT threads are not interchangeable due to their structural differences. Attempting to interchange them could lead to leaks and compromised connections.

Q 2: Which Thread Standard is More Common in Plumbing?

NPT threads are more commonly used in plumbing due to their sealing capabilities and ability to prevent leaks in water and gas pipes.

Q 3: What Are Some Applications Where SAE Threads are Preferred?

SAE threads are preferred in applications involving hydraulic systems and high-pressure environments where leak prevention is crucial.

Q 4: Are SAE and NPT Threads Equally Secure?

Both SAE and NPT threads offer secure connections, but their design differences make them more suitable for specific applications.

Q 5: Can You Convert Between SAE and NPT Threads?

Converting between SAE and NPT threads is not recommended due to their structural differences. It’s best to choose the

Conclusion

In the world of threads, SAE and NPT stand as two distinct standards, each catering to specific needs. SAE threads excel in hydraulic and high-pressure applications, while NPT threads shine in plumbing and general industrial settings. Understanding the differences and choosing the right thread type for your project is essential for ensuring optimal performance and leak-free connections.

Post time: Sep-14-2023