In the intricate world of hydraulic systems, the seamless flow and control of hydraulic fluid are paramount. It's a symphony of precise movements and forces. At the heart of this symphony lies a crucial component - AN hydraulic fittings. These fittings are the unsung heroes, the cornerstone of fluid power systems.

Let's delve into the essence of hydraulic systems and understand why AN hydraulic fittings are indispensable in this orchestration.

Definition and Purpose

AN hydraulic fittings are specialized connectors that join the various components of a hydraulic system. Their primary purpose is to create leak-proof connections and pathways for hydraulic fluid, allowing it to travel from one part of the system to another. In essence, AN hydraulic fittings act as the conduits that maintain the fluid's flow and pressure, ensuring the system operates optimally.

Historical Background

The "AN" in AN hydraulic fittings stands for Army-Navy, indicating its origins. Initially developed during World War II for aircraft applications, AN fittings gained prominence due to their precision and reliability. Over the years, their usage has expanded beyond aviation, becoming a standard in numerous industries that rely on hydraulic systems.

Anatomy of AN Hydraulic Fittings

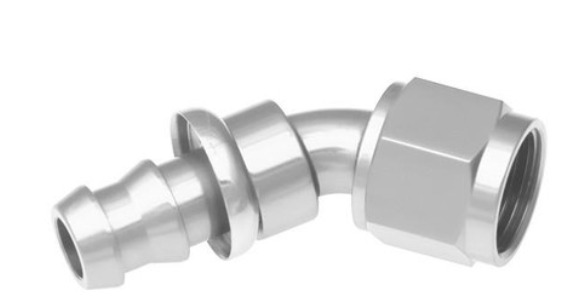

45-degree AN push Lock Hose End

➡️ Core Components

AN hydraulic fittings consist of several essential components. The fitting's body forms the main structure, providing the connection and sealing points. The flare, present at the end of the fitting, ensures a tight seal with the hose. The nut, often knurled for easy gripping, secures the connection, and the sleeve or ferrule reinforces the hose's connection to the fitting, enhancing its integrity.

➡️ Materials Used

Materials play a critical role in AN hydraulic fittings, determining their durability and performance. Common materials include stainless steel, aluminum, brass, and specific alloys. The choice of material depends on factors such as the fluid being used, the pressure requirements, and the environmental conditions the fittings will be exposed to.

Types of AN Hydraulic Fittings

➡️ Straight Fittings

Straight fittings, as the name implies, maintain a straight alignment between the connected components. They are the simplest and most common type of AN hydraulic fitting, suitable for direct connections without any bends or angles.

➡️ Elbow Fittings

Elbow fittings have a 90-degree or 45-degree bend, allowing the fluid to change direction smoothly. They are ideal for navigating tight spaces or achieving specific orientations within the hydraulic system.

➡️ Tee Fittings

Tee fittings resemble the letter 'T,' branching out into two directions. They are used when one hydraulic line needs to be split into two, facilitating efficient fluid distribution.

➡️ Union Fittings

Union fittings join two hoses or tubes, enabling a quick and secure connection or disconnection. They are essential for maintenance or replacement tasks, providing ease and flexibility.

Advantages of AN Hydraulic Fittings

✅ Leak-Resistant Connections

One of the primary advantages of AN hydraulic fittings is their exceptional leak resistance. The snug fit and sealing mechanisms ensure that hydraulic fluid remains contained within the system, preventing wastage and maintaining efficiency.

✅ High-Pressure Applications

Hydraulic systems often operate under high pressure. AN hydraulic fittings are designed to withstand these high-pressure conditions, ensuring the integrity of the connections even in demanding applications.

✅ Versatility and Compatibility

AN hydraulic fittings come in a variety of sizes, configurations, and materials, offering versatility. This versatility allows them to be compatible with a wide range of hydraulic systems, providing a tailored fit for specific needs.

Selecting the Right AN Hydraulic Fitting

✅ Factors to Consider

Choosing the right AN hydraulic fitting involves considering factors such as the hydraulic system's pressure and temperature requirements, the type of hydraulic fluid being used, and the specific application needs. A careful evaluation of these factors ensures the fitting meets the system's demands effectively.

✅ Common Mistakes to Avoid

In the process of selecting AN hydraulic fittings, it's crucial to avoid common mistakes like mismatched fittings, incorrect sizing, or neglecting material compatibility. These errors can lead to leaks, malfunctions, and even safety hazards within the hydraulic system.

Maintenance and Care of AN Hydraulic Fittings

✅ Regular Inspections

Regular inspections of AN hydraulic fittings are essential to detect any signs of wear, damage, or leaks. Timely identification of issues allows for prompt maintenance and prevents potential system failures.

✅ Lubrication and Cleaning

Lubrication and cleaning are vital aspects of AN hydraulic fitting maintenance. Applying the appropriate lubricants ensures smooth fitting operation and enhances their lifespan. Additionally, periodic cleaning helps remove debris or contaminants that could obstruct the fluid flow or cause damage.

Proper maintenance of AN hydraulic fittings ensures that the hydraulic system operates efficiently and safely, maintaining its overall performance and longevity.

Conclusion

AN hydraulic fittings may appear as simple components, but they are the backbone of any hydraulic system. Their significance in ensuring seamless fluid flow, leak-free connections, and overall system reliability cannot be overstated. Understanding the types, materials, and advantages of AN hydraulic fittings is essential for harnessing the full potential of hydraulic systems.

In the dynamic world of fluid power systems, AN hydraulic fittings stand as stalwarts, upholding the integrity and efficiency of these systems. Their evolution from aircraft applications to versatile components for diverse industries underscores their fundamental role in modern technology.

Post time: Nov-08-2023