In the intricate world of fluid mechanics and engineering, the choice of fittings can significantly impact the efficiency, reliability, and safety of any system. Two common types of fittings, JIC (Joint Industry Council) and AN (Army/Navy), often find themselves in the spotlight of engineering decisions.

Understanding the nuances between these fittings is crucial for professionals aiming for precision connections in their applications.

Decoding JIC Fittings: Precision at its Core

JIC fittings, short for Joint Industry Council fittings, are renowned for their robust construction and leak-free performance. These fittings boast a 37-degree flare seating surface, providing a reliable metal-to-metal seal. Commonly used in hydraulic systems, JIC fittings offer ease of assembly and disassembly, making them a favorite in applications where frequent maintenance and adjustments are necessary.

Key Features of JIC Fittings:

➡️ 37-Degree Flare Angle: The defining characteristic that ensures a tight, secure fit.

➡️ Versatility: Compatible with a wide range of fluids, making them versatile for various industries.

➡️ Rugged Construction: Built to withstand high pressures and challenging environments.

➡️ Easy Identification: Marked with sizing for easy recognition, simplifying installation procedures.

How to Determine if JIC Fittings are Right for You?

➡️ Consider the Application: JIC fittings are ideal for hydraulic systems, heavy machinery, and industrial applications where durability and ease of maintenance are paramount.

➡️ Evaluate the Environment: If your system operates in challenging conditions involving high pressures and varying temperatures, JIC fittings are a reliable choice.

AN Fittings: Precision Perfected

AN fittings, standing for Army/Navy fittings, have a long-standing reputation for their precision engineering, particularly in the aerospace and motorsport industries. These fittings employ a 37-degree flare, similar to JIC fittings, but are meticulously standardized for military and aviation use, ensuring utmost accuracy and consistency.

Key Features of AN Fittings:

➡️ Military-Grade Precision: Engineered to military standards, ensuring uniformity and reliability.

➡️ Lightweight Design: Ideal for applications where weight is a critical factor, such as aircraft and high-performance vehicles.

➡️ Corrosion Resistance: Often made from aluminum or stainless steel, AN fittings are resistant to corrosion, ensuring longevity and durability.

➡️ Wide Application: While rooted in aviation, AN fittings find applications in diverse industries requiring precision fluid connections.

Choosing the Right Fitting for Your Application

Considerations for JIC Fittings:

➡️ Hydraulic Systems: JIC fittings are a popular choice in hydraulic systems due to their leak-free design and ease of maintenance.

➡️ Industrial Machinery: Industries relying on heavy machinery often opt for JIC fittings for their durability and reliability in high-pressure environments.

Considerations for AN Fittings:

➡️ Aerospace and Motorsport: AN fittings are the go-to choice in these industries due to their precision, lightweight design, and resistance to vibration and high temperatures.

➡️ Performance Vehicles: Enthusiasts and professionals alike favor AN fittings for high-performance vehicles, where precision and reliability are paramount.

Choosing Between JIC and AN Fittings

➡️ Consider Weight: If your application involves weight-sensitive environments like aircraft or racing cars, AN fittings, being lightweight, offer a significant advantage.

➡️ Evaluate Precision Needs: For applications demanding utmost precision and consistency, especially in aerospace and motorsport, AN fittings are the preferred choice.

Are AN and JIC Compatible?

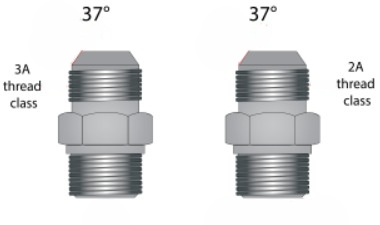

First Photo: AN Second Photo: JIC

Yes, with Adapters: While AN and JIC fittings have different flare angles (37-degree for both but with different tolerances), they can be made compatible using adapters specifically designed to bridge the gap between the two.

Conclusion: Making the Right Connection

In the realm of fluid connections, the choice between JIC and AN fittings boils down to the specific requirements of the application. While JIC fittings offer robustness and versatility, AN fittings bring military-grade precision and lightweight design to the table. Both have proven their mettle in demanding industries, ensuring seamless fluid connections in critical systems.

When making your decision, it's crucial to assess the unique needs of your project. Whether you prioritize ease of maintenance, durability, or precision engineering, both JIC and AN fittings stand as testament to human ingenuity, offering unmatched solutions for your fluid connection needs.

Post time: Nov-02-2023