Hydraulic systems are vital in many industries, smoothly transferring power and fluids. Amidst the complexity of hydraulic connections, one acronym stands out – JIC. In this article, we will talk about hydraulic fittings. We will focus on JIC threads and their importance.

Understanding JIC Threads

JIC, or Joint Industry Council, is a type of hydraulic fitting used in fluid power systems. This abbreviation stands for a type of thread. It also refers to rules that ensure hydraulic connections work properly.

The roots of JIC threads trace back to the need for a standardized fitting in hydraulic systems. The Joint Industry Council was made up of experts from different industries. They played a key role in setting these standards. Over time, JIC threads have evolved to meet the needs of modern hydraulic applications.

The significance of JIC threads lies in their versatility and widespread use. They offer a dependable way to move fluids in different industries. They are easy to put together, keep everything sealed, and work well with other parts.

JIC Standards and Specifications

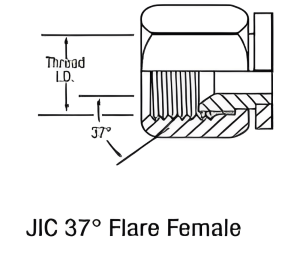

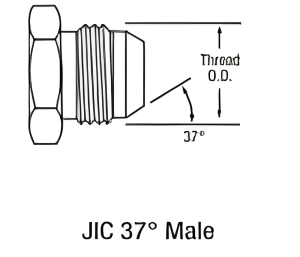

JIC Flare Fittings (37° Flare)

JIC threads stand out from other hydraulic fittings because of their unique 37° flare angle. The design helps seal and makes JIC fittings good for high-pressure use.

JIC Thread Sizes

JIC threads have different sizes, so hydraulic systems can be designed with flexibility. JIC thread sizing has options for small parts and large ones for heavy machinery.

Material Standards for JIC Fittings

To ensure durability and reliability, JIC fittings adhere to strict material standards. We use stainless steel, brass, and carbon steel because they have unique properties. These properties include corrosion resistance and strength.

Advantages of JIC Threads

Enhanced Sealing Integrity

The 37° flare angle of JIC threads creates a secure and leak-resistant connection. Fluid leakage in hydraulic systems is a big problem. It can cause inefficiencies and safety issues.

Ease of Assembly and Disassembly

JIC fittings are easy to put together and take apart, which is a major advantage. The design of the flare makes connecting things easier. During installation and maintenance, this saves time and effort.

Compatibility Across Manufacturers

JIC standards apply to many manufacturers, allowing different brands to work together. When different parts need to work well together, compatibility is really important.

Common Applications of JIC Fittings

Aerospace Industry

JIC fittings are commonly used in the aerospace industry because they are precise and reliable. Aircraft hydraulic systems like them because they can handle high pressure and stop leaks.

Industrial Machinery

JIC threads are important in many machines, like manufacturing equipment and heavy machinery. JIC fittings are versatile and reliable, which helps make applications efficient and safe.

Automotive Sector

JIC fittings are a small but strong solution used in the automotive industry. They work well in tight spaces and meet high-performance standards. These devices can be used in cars for braking systems and power steering, showing how versatile they are.

JIC vs. Other Hydraulic Fitting Standards

JIC vs. NPT Threads

While JIC threads utilize a flare design, NPT (National Pipe Thread) threads rely on a tapered design. The choice depends on the system’s needs, with JIC often chosen for its good seals.

JIC vs. ORFS Fittings

Compared to the O-Ring Face Seal (ORFS) fittings, JIC threads offer a different sealing mechanism. ORFS fittings use an O-ring to make a seal. JIC relies on metal-to-metal contact between flared surfaces. Each type has its advantages, and the choice depends on the application’s demands.

Proper Installation and Torque Requirements

Importance of Correct Installation

Proper installation is paramount for the optimal performance of JIC fittings. To avoid leaks and keep the hydraulic system strong, follow the instructions and use the right amount of force when installing.

Recommended Torque Values for JIC Fittings

Torque requirements vary based on the size and material of JIC fittings. To apply the correct torque, it is important to refer to the manufacturer’s specifications. Over tightening or under tightening can cause compromised connections and system failures.

Preventing Common Installation Mistakes

Mistakes during installation, like cross-threading and sealant misuse, can affect JIC fittings’ effectiveness. To avoid problems with your hydraulic system, pay attention to details and follow best practices.

Troubleshooting JIC Fittings

Identifying and Addressing Leaks

Even with the robust design of JIC threads, leaks can still occur. To prevent fluid loss, maintain system efficiency, and avoid damage, promptly find and fix leaks.

Dealing with Cross-Threaded Connections

Cross-threading can occur during installation, compromising the integrity of the connection. If you find twisted connections, fix them right away by separating and reassembling the fittings correctly.

Regular Maintenance for Longevity

Routine maintenance is key to ensuring the longevity of JIC fittings. To keep the hydraulic system reliable and working well, regularly check for wear and damage. Replace parts as needed.

JIC Fittings in the Context of Fluid Conveyance

Role of JIC Threads in Fluid Power Systems

JIC threads are very important in fluid power systems. These systems need to reliably carry hydraulic fluid for machinery to work. JIC fittings help fluid power work better by providing secure connections.

Ensuring Fluid Integrity in Hydraulic Applications

To keep hydraulic systems working properly, it’s crucial to keep the fluid clean and contaminant-free. JIC threads are made to touch each other, which keeps things from leaking or getting dirty.

Challenges and Solutions in Fluid Conveyance

JIC fittings are good for moving fluids. However, they can have problems with heat, corrosive fluids, and high pressure. Manufacturers always come up with new ideas to solve these problems. Their materials and designs strengthen JIC fittings for various hydraulic situations.

Conclusion

JIC threads in hydraulic fittings are a common and dependable choice for fluid power systems. Professionals from various industries must grasp JIC threads, including benefits, installation, and troubleshooting.

JIC threads are important in hydraulic systems. They help with efficiency and reliability. They also help with transferring power and fluids smoothly in different applications.

Post time: Dec-22-2023