When it comes to hydraulic systems, adherence to standards is paramount. SAE J518, also known as the Code 61 and Code 62 flange connections, stands tall as a foundational benchmark in the hydraulic engineering realm. In this detailed guide, we will unravel the intricate details of SAE J518 standards, aiming to provide you with unparalleled insights and understanding.

Understanding SAE J518: An In-Depth Exploration

SAE J518 standards encompass a range of specifications crucial for hydraulic connections. From design dimensions to performance requirements, this standard ensures the seamless functioning of hydraulic components. The Code 61 and Code 62 flange connections, integral parts of SAE J518, guarantee optimal performance and safety in hydraulic applications.

Differentiating SAE J518 Code 61 and Code 62: Choosing the Right Flange Connection

Source: SAE International Standard

One of the key dilemmas in hydraulic engineering lies in choosing between Code 61 and Code 62 flange connections. Understanding their differences is vital for making an informed decision.

Code 61 flanges are typically lower in pressure rating but are more compact, making them suitable for applications with space constraints. On the other hand, Code 62 flanges offer higher pressure ratings, ensuring robust performance in high-pressure hydraulic systems.

Please Read: ➡️ “SAE J1453: Setting The Standard For Hydraulic Fittings“

SAE J518 Split Flange Specifications

|

ANSI standard |

MSS SP44, ANSI B16.47, ANSI B16.48, ANSI B16.36, ANSI B16.5, |

|

German Standard |

DIN 2673, DIN 2636, DIN 2637, DIN 2527, DIN 2576, DIN 2656, DIN 2566, DIN 2573, DIN 2641, DIN 2642, DIN 2634, DIN 2629, DIN 2638, DIN 2655, DIN 2633, DIN 2627, DIN 2628, DIN 2631, DIN 2632, DIN 2635, |

|

EN Standard |

EN 1092 |

|

BS Standard |

BS 4504, BS 4504, BS1560, BS10 |

|

Types |

Hydraulic SAE flanges |

|

Pressure Ratings (Bar) |

3000 PSI & 6000 PSI |

|

Size (inch) |

1-5 |

|

Materials (ASTM A182) |

Alloy Steel, Stainless Steel, Carbon Steel, Duplex, Super Duplex, Nickel Alloy, Low Temperature |

|

Flange Face Type |

Flat Face, Lap-Joint Face, Ring Type Joint, Raised Face, Small Tongue, Large Male-Female, Small Male-Female, Large Tongue & Groove Flanges |

Material Selection: A Crucial Aspect of SAE J518 Compliance

Ensuring compliance with SAE J518 standards extends beyond understanding dimensions and pressure ratings. The choice of materials plays a pivotal role in meeting the standard’s requirements. High-quality materials, such as stainless steel or carbon steel, are commonly used for manufacturing flange connections. These materials not only guarantee durability but also resist corrosion, enhancing the longevity of hydraulic systems.

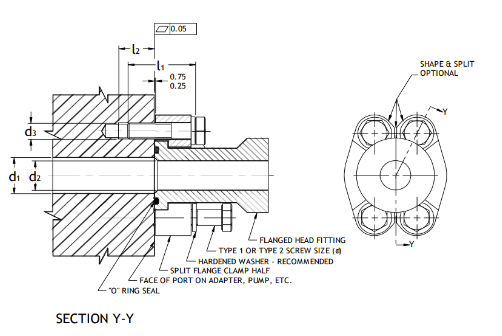

Flawless Installation: The Key to Optimal Performance

Even the highest-quality flange connections can underperform if not installed correctly. Following precise installation procedures outlined in SAE J518 standards is non-negotiable. Proper alignment, accurate torque application, and appropriate sealing techniques are vital for preventing leaks and ensuring the longevity of hydraulic systems.

Adherence to SAE J518: Ensuring Safety and Reliability

Compliance with SAE J518 standards is not just a matter of fulfilling regulatory requirements; it’s a commitment to safety and reliability. Hydraulic systems that adhere to these standards exhibit enhanced performance, reduced downtime, and increased operational efficiency. Moreover, they contribute significantly to the safety of personnel and equipment, making them indispensable in various industries.

➡️ “What is the standards for hydraulic and pneumatic systems? Read it here! “⬅️

Conclusion: Elevating Your Hydraulic Systems to Unprecedented Heights

Understanding and implementing SAE J518 standards is not merely a choice; it’s a necessity for any organization involved in hydraulic engineering. By choosing the appropriate flange connections, selecting high-quality materials, ensuring flawless installation, and prioritizing compliance, you can elevate your hydraulic systems to unprecedented heights of performance, safety, and reliability.

Post time: Nov-17-2023