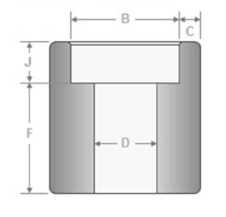

A half coupling is a short pipe used for connecting a small branch to a larger pipe. This part helps connect two pipes or tubes using a socket or threaded end. The socket or threaded end is only on one side. You can use the other end to weld or attach it to the existing pipes.

Anatomy of Pipe Half Couplings

Small but strong, pipe half couplings are important parts of piping systems. The couplings are designed to connect and move fluids easily and efficiently. The anatomy includes important parts like connectors, sealant features, and strong materials. They make sure the product lasts and works well in different situations.

Professionals and engineers can make smarter choices by knowing how their bodies work. This helps when adding couplings to piping networks.

How Pipe Half Couplings Work

The mechanism behind pipe half couplings is a testament to engineering precision. These connections quickly and efficiently join pipes together. They can also be easily disconnected when necessary. The sealant is important because it keeps everything together and prevents leaks.

When we study how these couplings work, we discover a clever engineering symphony. Each part helps the whole system.

Types of Pipe Half Couplings

Pipe half couplings are available in various types for specific needs and uses. threaded, socket weld, and butt weld half couplings are among the diverse options available. The type of pipe chosen depends on things like the fluid, pressure needs, and system design. To select the correct coupling, you must understand the features of each type.

What is the Difference Between Half and Full Coupling?

Pipe Half Coupling Threaded Full Pipe Coupling

Distinguishing between half and full couplings lies in the scope of their coverage. While a full coupling encapsulates the entire circumference of the pipe, a half coupling covers only half of it. The difference affects how they are used. Half couplings are a popular choice in tight spaces or specific designs. They provide a partial connection.

To make accurate decisions during piping projects, it helps to understand this difference.

Advantages of Using Pipe Half Couplings

The utilization of pipe half couplings brings forth a myriad of advantages. One of the main benefits is that it is efficient to connect and disconnect pipes. You can also easily modify systems and it is cost-effective. These couplings are important parts that balance strength and flexibility in structures. Exploring the advantages reveals their value in various industries. It is important to use them.

Common Industries and Applications

Pipe half couplings are widely used in various industries. These industries include plumbing, construction, and oil and gas. Precision and reliability are crucial in manufacturing and industry. They can be used there. Professionals can come up with new ideas by knowing the popular industries and uses.

Compatibility with Various Materials

Pipe half couplings can be made of various materials like steel, copper, and PVC. Their ability to fit into different pipes makes them work well in any system, no matter the material used. To make sure things work well and last long, engineers must consider these compatibility factors. These factors include the material’s characteristics and the conditions in the environment.

Challenges in Using Pipe Half Couplings

Despite their advantages, challenges in using pipe half couplings exist. Engineers may encounter issues such as corrosion, rust, and potential leakages. To address these challenges, we need to take a careful approach. This involves choosing the right materials, installing them correctly, and maintaining them regularly.

Navigating challenges is crucial for pipe half couplings in tough industries.

Expert Insights and Recommendations

Gathering expert insights and recommendations is invaluable for ensuring optimal usage and performance. Experts in the field have lots of experience and can help you understand and get better. Here are key insights and recommendations from industry experts:

Material Selection Matters:

Material selection is crucial for pipe half couplings. It’s important to consider the rust resistance of something for good performance. Also, think about its durability and compatibility with the carried liquid.

Precision in Installation:

Precise installation is crucial. Experts say that to prevent leaks and increase the lifespan of the coupling, it is important to align it correctly. Additionally, a good seal and proper torque are necessary.

Environmental Considerations:

Consider environmental conditions for pipe half couplings. Experts recommend considering factors such as temperature changes and exposure to corrosive substances. They also suggest assessing potential impacts on the overall system.

Regular Maintenance Practices:

Regular maintenance is crucial for pipe half couplings. Experts recommend regular inspections to check for wear, corrosion, or problems. This helps prevent unexpected failures by addressing them promptly.

Understanding Application Specifics:

Industries and applications vary, and experts stress understanding specific needs. Consider pressure, fluid, and environmental factors to choose the right pipe half coupling.

Innovation and Advancements:

Stay updated on tech advancements for pipe half couplings. Experts advise monitoring trends, new materials, and technologies to enhance efficiency and reliability.

Collaboration and Knowledge Sharing:

Experts emphasize collaboration and knowledge sharing in the industry. Professionals using pipe half couplings benefit from sharing experiences and participating in forums. Building networks also helps create a collective understanding.

Customization for Specific Needs:

Customization is crucial as not all applications are alike. Customize solutions to meet specific needs for optimal performance of pipe half couplings. These solutions are tailored for use in different industries.

Future-Proofing Strategies:

Prepare for the future by being adaptable. Use strategies like modular designs, flexible materials, and forward-looking approaches suggested by experts.

Comparisons with Other Coupling Types

Pipe half couplings, full couplings, and union couplings each have unique attributes. Comparing them helps us see the differences. Understanding the differences between things helps in making good decisions. During piping projects, it is important to have this understanding. Professionals can use this analysis to choose the best coupling for specific applications. It enriches their knowledge.

1. Pipe Half Couplings vs. Full Couplings

➡️ Coverage:

Pipe Half Couplings: Cover only half of the pipe circumference.

Full Couplings: Encompass the entire circumference of the pipe.

➡️ Use Cases:

Pipe Half Couplings: Ideal for scenarios with space constraints or specific design requirements.

Full Couplings: Suited for applications where complete pipe coverage is necessary.

➡️ Flexibility:

Pipe Half Couplings: Offer flexibility in system modifications due to partial coverage.

Full Couplings: Provide stability and uniformity with complete coverage.

2. Pipe Half Couplings vs. Union Couplings

➡️ Joining Mechanism:

Pipe Half Couplings allow pipes to be connected through a socket or threaded end. Only one side has this end.

Union Couplings: Allow pipes to be disconnected and reconnected easily.

➡️ Structure:

Pipe Half Couplings: Fixed structure with a permanent connection.

Union Couplings: Comprise two threaded components for easy disassembly.

➡️ Application Scope:

Pipe Half Couplings: Commonly used for permanent connections in various industries.

Union Couplings: Applied in situations where frequent disassembly is required.

3. Pipe Half Couplings vs. Threaded Couplings

➡️ Attachment Method:

Pipe Half Couplings: Can have threaded or socket ends.

Threaded Couplings: Specifically designed with threaded ends for connection.

➡️ Ease of Installation:

Pipe Half Couplings: May require welding or fastening on one end.

Threaded Couplings: Directly screw onto pipes, simplifying the installation process.

➡️ Adaptability:

Pipe Half Couplings: Offer adaptability in connecting different pipe sizes and materials.

Threaded Couplings: Limited to pipes with matching threaded ends.

Also, read↘️↘️:

Ferrule Tube Fittings: Enhancing Fluid Connections

Unlocking The Secrets Of JIS Flange: A Comprehensive Guide

The ABCs Of JIC Fittings Specifications Unveiled

Conclusion

Half couplings on pipes help fluids flow smoothly through piping systems. Engineers and professionals must understand the anatomy, functionality, and advantages for industrial applications. In the world of pipe half couplings, size doesn’t make things less impactful. It actually makes them more efficient and adaptable in different piping scenarios.

Post time: Jan-05-2024