In the realm of fluid power systems, hydraulic hose couplings play an indispensable role in ensuring the seamless transfer of power and fluids. These essential components are the linchpin of hydraulic machinery, enabling the precise and efficient operation of equipment across various industries.

In this comprehensive guide, we delve deep into the intricacies of hydraulic hose couplings and couplers, shedding light on their types, applications, benefits, and installation techniques, to provide you with an unparalleled understanding of these critical components.

Unveiling Hydraulic Hose Couplings and Couplers

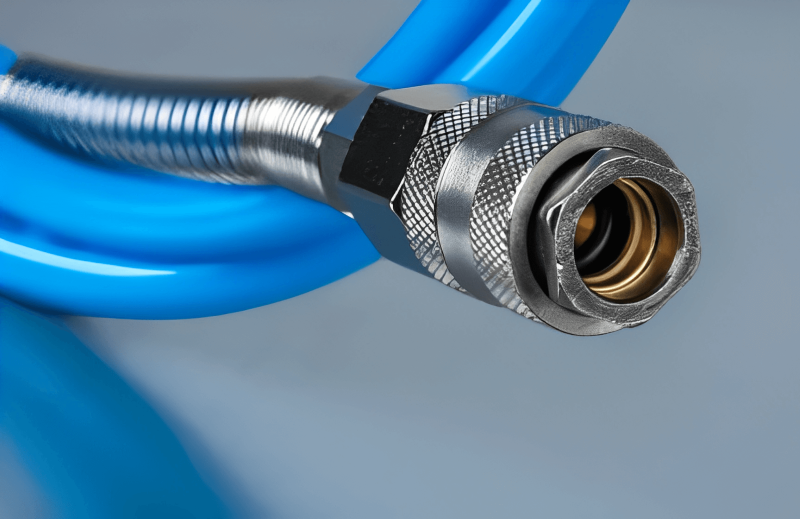

Hydraulic hose couplings, commonly referred to as couplers, are mechanical connectors that join hydraulic hoses to components, valves, or machinery. These couplings facilitate the transmission of hydraulic fluid and power, ensuring the flawless operation of heavy machinery, construction equipment, and other hydraulic systems.

The Diverse Types of Hydraulic Hose Couplings

Threaded Hydraulic Hose Couplings

Threaded couplings, also known as screw-type couplings, are among the most prevalent in hydraulic systems. These couplings feature male and female components with interlocking threads that ensure a secure and leak-free connection. The National Pipe Thread (NPT) and British Standard Pipe Parallel (BSPP) are two widely used threaded coupling standards.

Quick-Disconnect Hydraulic Hose Couplings

Quick-disconnect couplings offer the advantage of rapid hose connections and disconnections. These couplings feature a male and female component equipped with a mechanism that allows for swift attachment. They are particularly valuable in applications requiring frequent hose changes or maintenance.

Flat Face Hydraulic Hose Couplings

Flat face couplings are engineered for applications demanding minimal fluid leakage during connection and disconnection. These couplings feature flat mating surfaces that minimize spillage, making them ideal for high-pressure systems where fluid loss is unacceptable.

Choosing the Right Hydraulic Hose Coupling

Selecting the appropriate hydraulic hose coupling for your application is paramount to ensuring optimal system performance and longevity. Consider factors such as operating pressure, temperature, compatibility with hydraulic fluid, and the specific requirements of your machinery.

Benefits of High-Quality Hydraulic Hose Couplings

Investing in high-quality hydraulic hose couplings brings a host of benefits to your hydraulic systems. A secure and reliable coupling enhances overall system efficiency, minimizes downtime, reduces the risk of leaks, and promotes the safety of operators and surrounding equipment.

Proper Installation Techniques

Achieving a leak-free hydraulic connection begins with proper installation techniques. Follow these steps for a successful coupling installation:

Inspect Components: Thoroughly inspect the hose and coupling components for damage or wear before installation.

Clean Components: Ensure that all components are free from dirt, debris, and contaminants that could compromise the seal.

Lubricate O-Rings: Apply a compatible lubricant to O-rings and seals to facilitate smooth assembly and prevent damage.

Align and Push: Align the components and push them together until a positive stop is felt, indicating a secure connection.

Lock Mechanism: Engage the locking mechanism to secure quick-disconnect couplings.

Applications Across Industries

Hydraulic hose couplings find application across a diverse range of industries, including construction, agriculture, manufacturing, and mining. They enable the operation of heavy machinery, excavators, loaders, and hydraulic presses, showcasing their versatility and essential role in modern industrial processes.

Addressing FAQs

Q: Are hydraulic hose couplings interchangeable between different brands?

While compatibility can vary, it's generally advisable to use couplings from the same brand to ensure optimal performance.

Q: How do I identify the correct hydraulic hose coupling for my application?

Consult with hydraulic experts or manufacturers, considering factors like pressure, temperature, and fluid compatibility.

Q: Can hydraulic hose couplings be reused after disconnection?

It's recommended to inspect couplings after disconnection and replace any damaged components to ensure system integrity.

Q: Can I mix different types of hydraulic hose couplings in the same system?

Mixing couplings is not recommended, as it can compromise system efficiency and integrity.

Q: What maintenance practices can prolong the life of hydraulic hose couplings?

Regularly inspecting couplings for wear, cleaning mating surfaces, and ensuring proper lubrication contribute to their longevity.

Q: Are there alternatives to traditional hydraulic hose couplings?

Advanced technologies have led to the development of innovative coupling solutions, offering improved efficiency and reliability.

Conclusion

In conclusion, hydraulic hose couplings and couplers are the unsung heroes of hydraulic systems, enabling seamless power transmission and fluid movement. Threaded, quick-disconnect, and flat face couplings offer distinct advantages based on their designs and applications.

Choosing high-quality couplings, coupled with proper installation techniques, ensures system reliability, reduces downtime, and enhances overall operational efficiency. Whether in construction, agriculture, or manufacturing, the right hydraulic hose coupling ensures the smooth and uninterrupted functioning of machinery.

Post time: Aug-18-2023