In hydraulic systems, the proper selection and understanding of hydraulic fitting thread types are crucial for ensuring leak-free connections and optimal system performance. This article serves as a comprehensive guide to hydraulic fitting thread types, covering the most common standards, their features, and considerations for installation and maintenance.

Exploring Hydraulic Fitting Thread Types

Hydraulic fitting thread types refer to the specific thread standards used for connecting hydraulic components. These threads allow for the secure attachment of fittings to hoses, valves, cylinders, and other hydraulic system elements. It is important to match the thread type of a fitting with the corresponding thread type of the component to ensure a reliable and leak-free connection.

Common Hydraulic Fitting Thread Standards

There are several widely used hydraulic fitting thread standards, including the following:

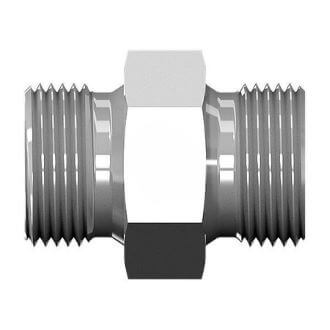

NPT (National Pipe Thread)

The NPT thread type with standard ASME B1.20.3 is commonly used in North America and is characterized by tapered threads. It features a male and female thread that gradually narrows, creating a seal by compressing the tapered threads together. NPT threads are popular for their ease of installation and are commonly found in applications involving low to medium hydraulic pressures.

BSPP (British Standard Pipe Parallel)

The BSPP thread type, also known as G (BSP) or BSPF (British Standard Pipe Female) utilizing ISO 12151-6, is widely used in Europe and other regions. Unlike NPT threads, BSPP threads are parallel, meaning they do not taper. These threads require the use of sealing washers or O-rings to create a tight seal. BSPP fittings are often used in higher pressure applications.

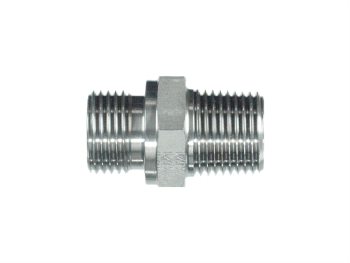

BSPT (British Standard Pipe Tapered)

The BSPT thread type, also known as R (BSP) or BSPT (British Standard Pipe Taper) utilizing DIN2999 and DIN3858 standards, is similar to NPT threads in that they are tapered. BSPT threads, however, have a different thread angle and are commonly used in smaller pipe sizes. It is important to note that BSPT and NPT threads are not interchangeable, and using the wrong thread type can result in leaks and improper connections.

JIC (Joint Industry Council)

JIC threads, also known as UNF (Unified National Fine) utilizing ISO 8434-2 and SAE_J514 standards, are widely used in hydraulic systems and feature a 37-degree flare. These threads provide a reliable and leak-free connection by using the flare and a metal-to-metal seal. JIC fittings are popular in high-pressure applications and are known for their ease of assembly.

ORFS (O-Ring Face Seal)

ORFS thread types use an O-ring to create a seal between the fitting and the component. These threads provide excellent resistance to leaks and are commonly used in high-pressure hydraulic systems. ORFS fittings are known for their reliability, ease of assembly, and resistance to vibration. These ORFS fittings utilize ISO 8434-3.

Metric Threads

Metric threads are commonly used in European and international hydraulic systems. They feature a straight, parallel design and are measured in millimeters. Metric threads offer compatibility with a wide range of components and are often found in applications with higher pressure requirements. These threads adhere to ISO 68-1, GB/T192, JIS B0205, GOST9150,ASME B1.13M, and BS3643-1.

Choosing the Right Hydraulic Fitting Thread Type

When selecting the appropriate hydraulic fitting thread type, consider the following factors:

✅ System Requirements

Understand the pressure, temperature, and flow requirements of your hydraulic system to determine the most suitable thread type.

✅ Component Compatibility

Ensure that the thread type of the fitting matches the thread type of the component to ensure a proper and secure connection.

✅ Application Specifics

Consider the environmental conditions, vibration levels, and other factors that may impact the performance of the hydraulic system.

Installation and Maintenance Considerations

Proper installation and maintenance are crucial for the longevity and performance of hydraulic systems. Follow these guidelines:

✅ Thoroughly clean and inspect the threads and mating surfaces before installing the fittings to ensure a clean and secure connection.

✅ Use the appropriate sealing methods, such as O-rings, washers, or flares, depending on the specific thread type.

✅ Follow manufacturer recommendations for torque specifications to avoid over-tightening or under-tightening, which can lead to leaks or damage.

✅ Regularly inspect the fittings for signs of wear, corrosion, or damage, and replace any components that show signs of degradation.

✅ Monitor the system for any signs of leaks, pressure drops, or other abnormalities that may indicate a fitting issue. Address any problems promptly to prevent further damage to the system.

Conclusion

Understanding hydraulic fitting thread types is essential for ensuring leak-free connections and optimal performance in hydraulic systems. By familiarizing yourself with common thread standards, considering system requirements, and following proper installation and maintenance practices, you can achieve reliable and efficient hydraulic connections. Pay attention to compatibility, application specifics, and manufacturer guidelines to ensure the longevity and reliability of your hydraulic system.

Frequently Asked Questions (FAQs)

Q1: Can I mix different hydraulic fitting thread types?

A1: It is generally not recommended to mix different hydraulic fitting thread types, as it can result in leaks and compromised connections. It is best to use fittings with matching thread types for optimal performance.

Q2: How do I determine the thread type of a hydraulic fitting?

A2: You can use thread gauges or consult the manufacturer's specifications to identify the thread type of a hydraulic fitting. It is important to accurately identify the thread type to ensure compatibility.

Q3: Can I use adapters to connect different thread types?

A3: Adapters can be used to connect different thread types, but it is essential to ensure that the adapter is specifically designed and rated for the intended connection. Improper use of adapters can lead to leaks and compromised system performance.

Q4: Are hydraulic fittings with tapered threads more prone to leaks?

A4: Proper installation and torquing of fittings with tapered threads, such as NPT or BSPT, can provide reliable seals and prevent leaks. Following manufacturer guidelines and using appropriate sealing methods are crucial for leak-free connections.

Q5: Are there thread sealants or tapes available for hydraulic fittings?

A5: Yes, thread sealants and tapes designed for hydraulic applications are available. These products can help enhance the sealing capabilities of hydraulic fittings, especially for tapered thread types. However, it is important to choose sealants compatible with the hydraulic fluid and follow the manufacturer's recommendations.

Post time: Jul-20-2023