Hydraulic systems are vital in various industries, ensuring the smooth operation of heavy machinery, vehicles, and equipment. A key component of these systems is the hydraulic fitting thread gauge, which plays a crucial role in establishing leak-free connections and maintaining system efficiency.

In this comprehensive article, we will delve into the world of hydraulic fitting thread gauges, their importance in achieving precision and reliability in hydraulic setups.

Hydraulic Fitting Thread Gauge – Ensuring Leak-Free Connections

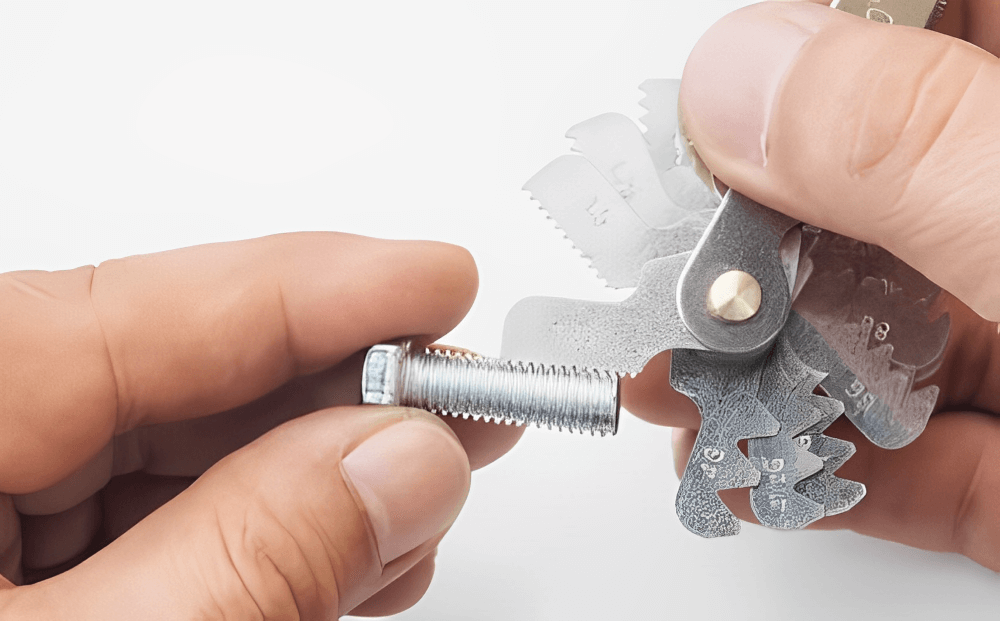

Hydraulic fitting thread gauges are specialized tools designed to measure the size, pitch, and thread characteristics of hydraulic fittings. These gauges play a critical role in ensuring leak-free connections between components, which is essential for the smooth operation of hydraulic systems. By accurately measuring the threads, these gauges allow technicians to identify potential issues, make adjustments, and ensure a perfect fit between components.

Importance of Proper Thread Measurement

Accurate thread measurement is crucial when dealing with hydraulic fittings. Mismatched threads can lead to leakages, loss of pressure, and potential system failures. The use of a hydraulic fitting thread gauge helps ensure that the threads are the right size and type for the specific application.

How to Use a Hydraulic Fitting Thread Gauge?

Using a hydraulic fitting thread gauge is a straightforward process that involves the following steps:

Step 1: Identify the type of thread on the fitting.

Step 2: Select the appropriate thread gauge for the identified thread type.

Step 3: Carefully thread the gauge onto the fitting until it fits snugly.

Step 4: Ensure the gauge aligns perfectly with the threads and note any deviations.

Step 5: Refer to the gauge markings to determine the thread size and pitch.

Advantages of Using Hydraulic Fitting Thread Gauges

The use of hydraulic fitting thread gauges offers several advantages, including:

Precision

Thread gauges ensure accurate measurements, leading to proper fitting selection.

Prevention of Leakages

Properly sized threads prevent leakages, improving system reliability.

Cost Savings

Accurate fittings reduce the need for replacements and repairs.

Enhanced Safety

Secure connections prevent accidents and potential hazards.

Common Mistakes to Avoid When Measuring Threads

To ensure the best results when using hydraulic fitting thread gauges, it’s essential to avoid common mistakes such as:

Ensuring Accurate Measurements

Always use the correct gauge for the specific thread type and size to get accurate measurements.

Proper Handling and Maintenance

Handle the gauges with care, and regularly clean and calibrate them to maintain accuracy.

Selecting the Right Hydraulic Fitting Thread Gauge

When choosing a hydraulic fitting thread gauge, several factors come into play. It’s essential to consider the following aspects:

1. Thread Type and Size

Different hydraulic systems use various thread types and sizes. Select a gauge that matches the threads used in your system to ensure accurate measurements.

2. Material and Durability

Opt for a gauge made from high-quality materials, as they will provide longevity and withstand the harsh conditions of hydraulic applications.

3. Calibration and Accuracy

Ensure the gauge is calibrated and provides precise measurements. Accuracy is crucial for leak-free connections.

4. Compatibility

Check that the gauge is compatible with the types of fittings and connectors commonly used in your hydraulic system.

5. Ease of Use

Choose a gauge that is user-friendly, with clear markings and easy-to-read measurements.

FAQs (Frequently Asked Questions)

How does a hydraulic fitting thread gauge work?

Hydraulic fitting thread gauges work by matching the thread of a hydraulic fitting with its corresponding counterpart on the gauge. The technician inserts the fitting into the gauge, and if it fits perfectly, the thread size, pitch, and type are accurately determined.

What are the common thread types in hydraulic systems?

Common thread types in hydraulic systems include NPT (National Pipe Thread), BSPP (British Standard Pipe Parallel), BSPT (British Standard Pipe Tapered), and metric threads.

Why is leak prevention essential in hydraulic systems?

Leak prevention is critical in hydraulic systems to maintain the system’s efficiency, prevent fluid loss, and ensure safety. Leaks can lead to pressure drops, reduced performance, and even catastrophic failures.

How often should hydraulic fittings be checked with a thread gauge?

Regular maintenance is essential to ensure hydraulic system efficiency. Experts recommend checking fittings with a thread gauge during scheduled maintenance intervals or whenever there are signs of leaks or performance issues.

Can a thread gauge be used for both internal and external threads?

Yes, some thread gauges are designed to measure both internal and external threads, offering versatility and convenience for technicians.

What are some signs of incorrect thread sizing in hydraulic fittings?

Incorrect thread sizing can result in loose connections, leaks, and reduced performance. Technicians should be vigilant for signs of leaks, pressure drops, and abnormal system behavior.

Conclusion

Hydraulic fitting thread gauges are indispensable tools for maintaining precision and reliability in hydraulic systems. They play a critical role in ensuring leak-free connections and optimal system performance across various industries.

By accurately measuring thread characteristics, these gauges contribute to the smooth operation of heavy machinery, vehicles, and equipment. Selecting the right thread gauge is essential to achieve accurate measurements and prevent potential leaks. Regularly checking hydraulic fittings with thread gauges during maintenance intervals is crucial for the efficiency and safety of hydraulic systems.

Post time: Jul-28-2023