We are embarking on a journey through hydraulic systems excellence. We will delve into the realm of EO fittings, a cornerstone in hydraulic engineering. The EO Fittings introduces us to a world where precision meets durability. Seamless connections are not just a necessity but an art form.

In this exploration, we uncover the distinctive features and benefits that set EO fittings apart. They shape the landscape of hydraulic fittings with unmatched performance and reliability.

Join us as we unravel the unparalleled advantages of EO fittings. They’re an indispensable choice in the intricate tapestry of hydraulic solutions.

What is EO Fitting?

EO fittings are short for Ermeto Original fittings. They are a pinnacle in fluid connector technology. They play a vital role in hydraulic and pneumatic systems. Their innovative design enhances performance and reliability. Understanding the intricacies of EO fittings unveils a world of engineering excellence.

Understanding EO Fittings Construction

A. Materials Used

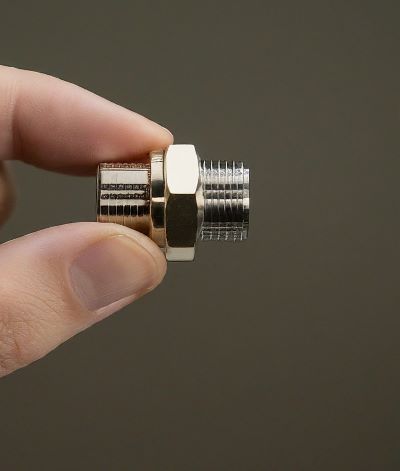

EO fittings are crafted from premium materials like stainless steel or carbon steel. They exhibit durability and resistance to corrosive environments. The choice of materials ensures longevity and robustness. This makes EO fittings a reliable solution for demanding industrial applications.

B. Precision Manufacturing

Precision is paramount in EO fittings. The manufacturing process employs cutting-edge techniques, guaranteeing tight tolerances and consistent quality. Crafting them with precision enhances their ability to withstand tough conditions. They do so with unwavering performance.

C. Threadless Design Explained

At the heart of EO fittings lies a revolutionary threadless design. EO fittings use advanced technology to establish a metal-to-metal seal. This is unlike traditional threaded fittings. This design minimizes the risk of leaks. It also simplifies the installation process, contributing to the fitting’s overall efficiency.

EO Fittings vs. Traditional Threaded Fittings

A. Performance Comparison

EO fittings surpass traditional threaded fittings in terms of performance. The absence of threads eliminates potential weak points. It results in a structurally robust connection that enhances overall system efficiency.

B. Leak Resistance

The threadless design of EO fittings significantly reduces the risk of leaks. The metal-to-metal seal ensures a secure connection, even under high-pressure conditions. Leak resistance is critical. This is especially true in applications where fluid containment is essential.

C. Ease of Installation

EO fittings offer unparalleled ease of installation. The absence of threads simplifies the assembly process. It reduces the time and effort required for fitting connections. This trait makes EO fittings a top choice. They are best in scenarios where fast installation is crucial.

Exploring the Variety of EO Fittings

A. Different Types and Configurations

EO fittings come in a diverse range of types and configurations. They cater to various system requirements. From EO tube fittings to EO hose fittings, the variety allows for flexibility in designing fluid systems. Each type is engineered with specific features to address different application needs.

B. Choosing the Right Fitting for Specific Needs

Selecting the appropriate EO fitting is crucial for optimal system performance. Pressure ratings, temperature resistance, and fluid compatibility are factors. They play a role in picking the right fitting for an application. Understanding these factors ensures the chosen fitting fits the system’s unique needs.

Check out these resources for your gain ⬇️⬇️⬇️

Applications Across Industries

A. Hydraulic Systems

EO fittings find extensive use in hydraulic systems. Precision and reliability are paramount in these applications. These fittings contribute to seamless fluid connections in hydraulic power transmission. They are used in heavy machinery and industrial equipment.

B. Pneumatic Systems

In pneumatic systems, EO fittings play a vital role in ensuring efficient air flow. The leak-resistant design and precision manufacturing make them suitable for applications. The applications range from pneumatic tools to intricate pneumatic control systems.

C. Industrial Machinery

EO fittings are integral components in diverse industrial machinery. They’re used in manufacturing plants and automated production lines. Their strong construction and performance help. They add to the reliability and efficiency of industrial processes.

FAQs: EO Fittings

Q: Are EO Fittings suitable for heavy-duty industrial applications?

➡️ EO Fittings are not limited by application. They excel in heavy-duty industrial settings. They provide robust solutions for a wide range of applications.

Q: How do EO Fittings ensure leak-free connections?

➡️ The innovative design of EO Fittings has a double-cutting ring. It guarantees a secure, leak-free connection. It ensures the integrity of hydraulic and pneumatic systems.

Q: Can EO Fittings be easily installed in existing systems?

➡️ Yes, EO Fittings are designed for easy installation. This makes them suitable for both new systems and retrofitting into existing setups.

Q: Do EO Fittings adhere to international standards?

➡️ EO Fittings conform to international standards and certifications. They earn global recognition for their quality and performance.

Q: What materials are EO Fittings made from?

➡️EO Fittings are crafted from high-quality materials, including stainless steel and carbon steel. This ensures durability and resistance to corrosion.

Q: Can EO Fittings be used with various tubing materials?

➡️ EO Fittings are compatible with a range of tubing materials. This provides flexibility in system design.

Conclusion

EO fittings stand as a testament to engineering excellence in fluid connector technology. Their threadless design, precise construction, and many uses make them a cornerstone. They improve the performance of hydraulic and pneumatic systems in many industries.

Industries demand efficiency and reliability and EO fittings remain at the forefront. They truly elevate fluid systems to new heights.

Post time: Feb-28-2024