Hydraulic elbows are unsung heroes in the world of fluid power systems, offering flexibility, durability, and seamless flow in hydraulic systems. In this comprehensive guide, we will explore hydraulic elbows and dive deep into the realm of hydraulic pipe joints.

We will uncover their significance, understand their sizes, explore their applications, and provide valuable insights for those seeking a better grasp of hydraulic pipe joints.

Hydraulic Elbow: What is It?

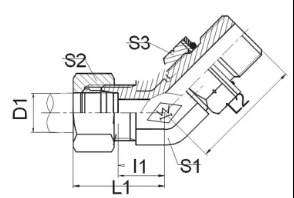

90° Elbow BSP Thread Adjustable Stud Ends O-Ring 45° Elbow Metric Male Cone

Hydraulic elbows, often referred to as hydraulic pipe joints, are fittings that allow for directional changes in hydraulic pipelines. They come in various angles, the most common being 90 degrees and 45 degrees, enabling hydraulic systems to navigate around obstacles and achieve optimal fluid flow.

Hydraulic Elbow Sizes

To understand hydraulic elbows better, it’s essential to grasp their sizes and dimensions. Hydraulic elbows are available in various sizes, typically measured in inches or millimeters. The choice of size depends on the specific hydraulic system’s requirements and space constraints.

Advantages of Using Hydraulic Elbows

The use of hydraulic elbows offers several advantages in hydraulic systems:

Space Efficiency: Hydraulic elbows allow for compact and efficient routing of hydraulic lines, saving valuable space.

Enhanced Fluid Flow: They ensure smooth and efficient fluid flow, reducing turbulence and pressure drop.

Durability: Made from robust materials like steel or brass, hydraulic elbows are built to withstand harsh conditions and high pressures.

Versatility: Their availability in various angles and sizes makes them adaptable to different hydraulic system configurations.

Considerations When Selecting Hydraulic Elbows

Selecting the right hydraulic elbow is critical to ensure system efficiency and longevity. Factors to consider include:

Size and Angle: Choose the size and angle that best suits your system’s requirements and layout.

Material: Opt for high-quality materials that are compatible with the hydraulic fluid used and the operating conditions.

Pressure Rating: Ensure the hydraulic elbow can handle the system’s maximum pressure without failure.

Corrosion Resistance: Consider the environment in which the hydraulic system operates and select a corrosion-resistant elbow if needed.

Installation and Maintenance

Proper installation and regular maintenance are key to the optimal performance and longevity of hydraulic elbows. Ensure secure connections, monitor for leaks, and perform routine checks to replace worn-out elbows promptly.

FAQs

Q1: Can hydraulic elbows be used in high-pressure hydraulic systems?

➡ Hydraulic elbows are available in various pressure ratings to suit different systems, including high-pressure applications.

Q2: How do I identify the correct size of a hydraulic elbow for my system?

➡ Measure the available space and the required angle within your hydraulic system to determine the right size and angle for the hydraulic elbow.

Q3: Are hydraulic elbows compatible with all hydraulic fluids?

➡ Hydraulic elbows should be selected based on compatibility with the specific hydraulic fluid used in your system to avoid chemical reactions or degradation.

Q4: What are the common materials used for hydraulic elbows?

➡ Hydraulic elbows are typically made from materials like stainless steel, brass, or carbon steel due to their durability and resistance to corrosion.

Q5: Where can I find reliable suppliers of hydraulic elbows?

➡ Reliable suppliers of hydraulic elbows can be found through industry-specific directories, online marketplaces, or by consulting with hydraulic experts and manufacturers.

Conclusion

In conclusion, hydraulic elbows are indispensable components in hydraulic systems, providing the flexibility and efficiency required for smooth fluid flow. Understanding their sizes, applications, advantages, and selection criteria empowers you to make informed decisions for your hydraulic systems, ensuring optimal performance and longevity.

Post time: Oct-11-2023