In the realm of hydraulic systems, the proper installation of hydraulic hose fittings is of utmost importance. These fittings serve as vital components that connect hydraulic hoses to various parts, ensuring a secure and leak-free connection.

This article will provide a detailed and comprehensive guide on how to install hydraulic hose fittings correctly. By following the step-by-step instructions outlined here, you can ensure a successful and efficient installation that will contribute to the optimal performance of your hydraulic system.

Understanding Hydraulic Hose Fittings

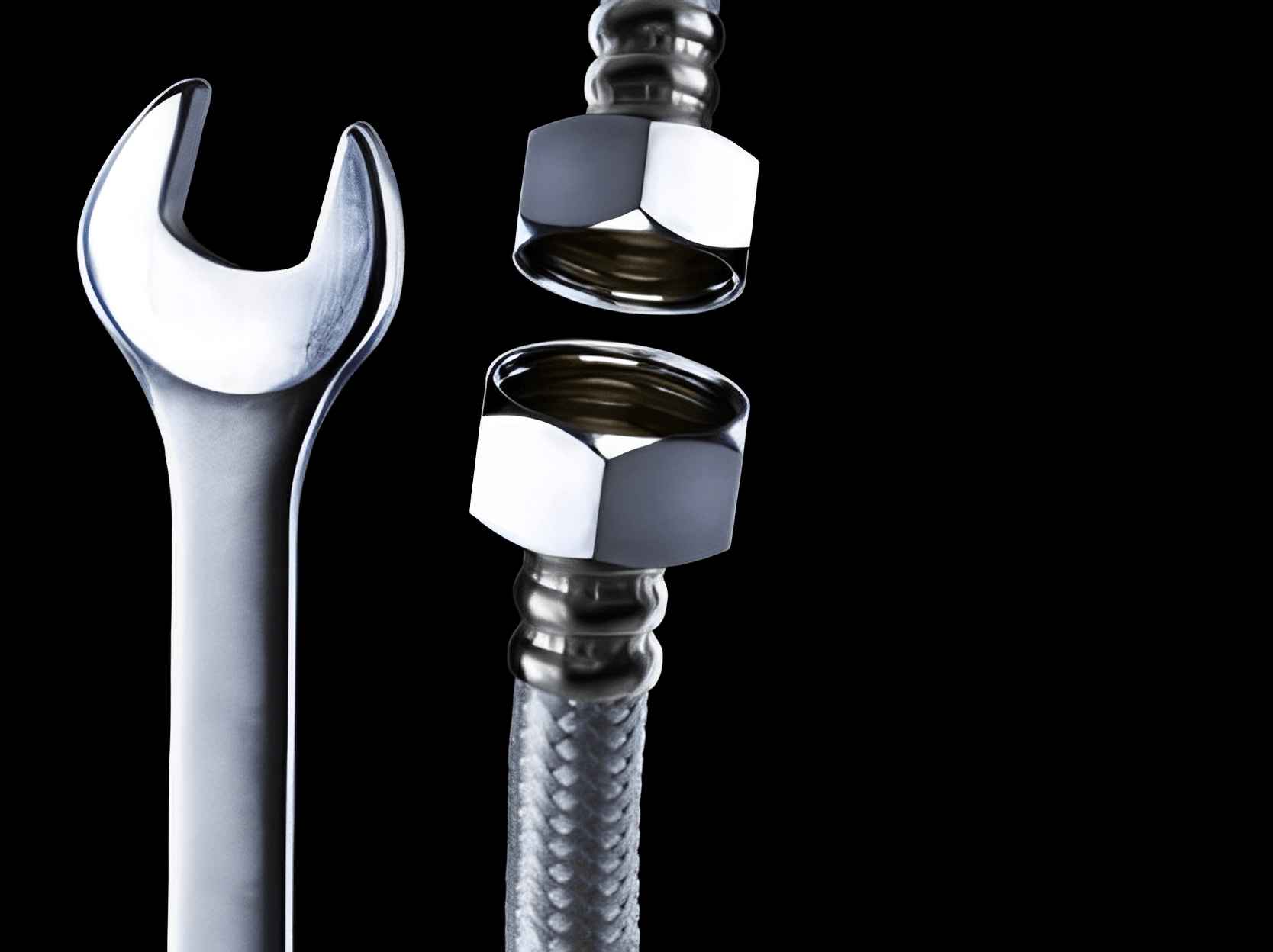

Before delving into the installation process, it’s essential to have a solid understanding of hydraulic hose fittings and their purpose. Hydraulic hose fittings are specialized components designed to connect hydraulic hoses to other hydraulic components, such as pumps, valves, and cylinders. These fittings come in various types, including hydraulic couplings, adapters, and connectors, each serving a specific function in the hydraulic system.

Preparing for Installation

Prior to commencing the installation process, it is crucial to prioritize safety and gather the necessary tools and equipment. Safety should always be the foremost concern when working with hydraulic systems. This involves wearing the appropriate protective gear, such as safety glasses and gloves, to safeguard against potential hazards.

In order to facilitate correct work, it is also crucial to make sure the work space is well-lit and free of any obstructions that can hinder the installation procedure. Before proceeding with the installation, it is essential to relieve the hydraulic pressure within the system to prevent any accidents or injuries.

Once safety measures are in place, gather the required tools, including wrenches, pliers, a hydraulic hose cutter, and thread sealant or tape.

Step-by-Step Installation Process

Selecting the appropriate fitting:

When installing hydraulic hose fittings, it is crucial to select the fitting that best suits your specific application. Consider factors such as the type of hydraulic hose, the pressure rating required, and the fitting compatibility with the rest of the hydraulic system. Referring to the manufacturer’s guidelines or consulting a hydraulic specialist can ensure the proper selection of fittings.

Measuring and cutting the hydraulic hose:

Using a hydraulic hose cutter, measure and cut the hydraulic hose to the desired length. It is essential to achieve a clean and precise cut, ensuring there are no frayed edges or debris that could compromise the fitting installation.

Attaching the fitting to the hose:

The proper alignment and orientation of the fitting are crucial for a secure and effective connection. Insert the fitting into the hydraulic hose, ensuring it is fully seated. To prevent leaks and ensure a tight seal, apply thread sealant or tape to the fitting threads before insertion.

Tightening the fitting securely:

Use the appropriate wrench or pliers to tighten the fitting onto the hydraulic hose. It is important to strike a balance between tightening the fitting securely and avoiding over-tightening, which could damage the fitting or the hose. Follow the manufacturer’s recommendations for the appropriate torque specifications to achieve the desired tightness.

Testing and Inspection:

Once the hydraulic hose fitting installation is complete, it is essential to conduct thorough testing and inspection to ensure its effectiveness and reliability.

Conducting a pressure test:

Gradually increase hydraulic pressure while closely monitoring all connections for any signs of leaks or abnormal behavior. Ensure that all fittings and connections are secure and properly sealed, as any leakage can compromise the performance of the hydraulic system.

Inspecting fittings and connections:

Carefully inspect all fittings, hoses, and connections for any signs of leaks, damage, or abnormalities. It is crucial to verify that all fittings are properly aligned and sealed to prevent any flow or performance issues. If any issues are detected, they should be promptly addressed to prevent potential damage to the hydraulic system.

Troubleshooting Common Installation Problems

During the installation process, certain common problems may arise. Here are a few troubleshooting tips to address them effectively:

Dealing with leaking fittings or connections:

If you encounter any leaks, check the tightness of the fittings and ensure proper alignment. If leaks persist, disassemble the fitting, clean all components thoroughly, and reapply thread sealant or tape before reassembling.

Correcting improper alignment or orientation:

Confirm that the fittings are aligned correctly with the hydraulic hose and other components. Ensure that the orientation matches the requirements of the hydraulic system to prevent any flow or performance issues.

Handling damaged or worn hydraulic hoses:

Regularly inspect the hydraulic hose for any signs of damage or wear. If any issues are detected, it is crucial to replace the hose promptly to maintain the integrity and reliability of the hydraulic system.

Maintenance and care:

To ensure the long-term performance and reliability of your hydraulic hose fittings, proper maintenance and care are essential.

Regular inspection and cleaning:

Regularly inspect the fittings and hoses for any signs of damage, wear, or contamination. Clean the fittings and connections to remove debris or contaminants that could impact their functionality. Regular inspection will help detect any issues before they escalate into larger problems.

Replacing worn or damaged fittings or hoses:

It is critical to repair any fittings or hoses that exhibit wear or damage right away. Follow the manufacturer’s guidelines for replacement and ensure that the new fittings or hoses are compatible with the hydraulic system.

Following manufacturer’s guidelines for maintenance:

Adhere to the maintenance guidelines provided by the manufacturer of the hydraulic hose fittings. This includes recommended intervals for inspection, lubrication, and replacement to optimize the performance and lifespan of the fittings.

Wrap Up

Proper installation of hydraulic hose fittings is critical for the reliable and efficient operation of hydraulic systems. You can make sure the installation procedure goes smoothly by carefully following the step-by-step instructions provided in this article. Remember to prioritize safety, select the appropriate fittings, and follow proper tightening techniques. Conduct thorough testing and inspection, and address any issues promptly. With regular maintenance and care, your hydraulic hose fittings will provide optimal performance and longevity for your hydraulic system.

Post time: Jun-08-2023