Hydraulic systems form the backbone of various industrial applications, from heavy machinery to construction equipment. At the heart of these systems lie common hydraulic fittings, essential components that ensure the seamless flow of hydraulic fluids. In this article, we’ll dive deep into the world of hydraulic fittings, discussing their types, functions, and the importance of standard connections.

The Vital Role of Hydraulic Fittings

Hydraulic fittings might appear unassuming, but their significance cannot be understated. These fittings are the linchpins that connect various hydraulic components, ensuring airtight seals and efficient fluid transfer. Whether it’s heavy-duty machinery or intricate medical equipment, hydraulic fittings play a critical role in maintaining operational fluidity.

Understanding Hydraulic Fittings: A Variety of Types

Threaded Fittings

Threaded fittings are a staple in hydraulic systems. They consist of male and female threads that screw together, creating a secure connection. These fittings are reliable and come in various thread types, such as NPT and BSPP.

Flange Fittings

Flange fittings are known for their robustness and durability. They involve two flanges connected with bolts, providing a tight connection that can withstand high pressures. Flange fittings are often used in demanding applications.

Compression Fittings

Compression fittings utilize compression rings to create seals. They are easy to install and suitable for soft tubing materials. However, they are not recommended for high-pressure applications.

Quick Disconnect Couplings

Quick disconnect couplings allow rapid connection and disconnection of hydraulic lines. They are essential in scenarios requiring frequent component changes or maintenance.

O-Ring Boss Fittings

O-Ring Boss fittings incorporate an O-ring to create a leak-free seal. They are commonly used in applications with high pressures and offer superior sealing capabilities.

Pipe Fittings

Pipe fittings, often used in plumbing, also find their place in hydraulic systems. They come in various shapes and sizes, facilitating different connection types.

What Are the Most Common Hydraulic Fittings?

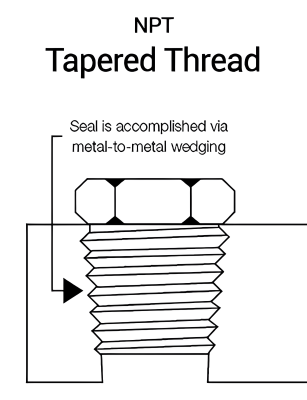

NPT (National Pipe Taper) Fittings

NPT fittings are tapered thread fittings widely used in North America. They provide a reliable seal, making them suitable for a range of hydraulic applications.

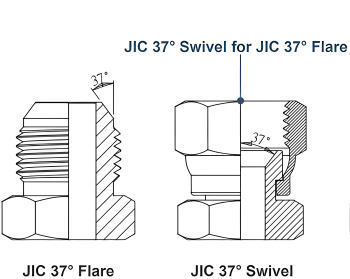

JIC (Joint Industry Council) Fittings

JIC fittings use a 37-degree flared cone to create a seal. They are versatile and well-suited for high-pressure applications, making them a popular choice.

ORFS (O-Ring Face Seal) Fittings

ORFS fittings employ an O-ring to create a tight seal on a flat face. They are known for their leak-free performance and resistance to vibrations.

Exploring Standard Hydraulic Connections

Importance of Standardization

Standard hydraulic connections bring uniformity to the industry. They ensure compatibility between components from different manufacturers, promoting interchangeability and ease of maintenance.

Benefits of Standard Hydraulic Connections

Standard connections reduce downtime by allowing quick replacement of components. They also simplify inventory management and streamline system design and maintenance.

Factors to Consider When Choosing Hydraulic Fittings

Fluid Compatibility

Selecting fittings compatible with the hydraulic fluid is crucial to prevent degradation or failure. Understanding the fluid’s composition is essential for choosing the right materials.

Pressure Rating

The pressure rating of fittings must match the operating pressure of the hydraulic system. Using fittings with inadequate pressure ratings can lead to leaks or catastrophic failures.

Temperature Range

Consider the temperature conditions the fittings will experience. Extreme temperatures can affect the materials’ integrity and impact the overall system performance.

Application Requirements

Different applications demand different types of fittings. Factors like vibration, movement, and environmental conditions influence the choice of fittings to ensure reliable performance.

The Interplay Between Fittings and Hydraulic Hoses

Hydraulic fittings and hoses work hand in hand. The compatibility of fittings and hoses ensures a secure connection that can withstand the pressures of the hydraulic system.

Ensuring Proper Installation and Maintenance

Proper installation is crucial to prevent leaks and ensure optimal performance. Regular maintenance, including inspections and replacements, helps prolong the lifespan of hydraulic fittings.

FAQs About Common Hydraulic Fittings

Q: What makes NPT fittings suitable for hydraulic systems?

A: NPT fittings’ tapered threads create a secure seal, preventing leaks in hydraulic applications.

Q: Are flange fittings only used in high-pressure applications?

A: Flange fittings are known for their durability, making them ideal for high-pressure scenarios, but they can be used in various applications.

Q: How do quick disconnect couplings improve maintenance efficiency?

A: Quick disconnect couplings allow rapid component changes, reducing downtime during maintenance tasks.

Q: Why is proper installation crucial for hydraulic fittings?

A: Proper installation ensures leak-free connections, preventing fluid loss and system inefficiencies.

Q: Can I mix and match different types of fittings within a hydraulic system?

A: It’s recommended to stick to a consistent fitting type to ensure compatibility and reliable performance within the system.

Conclusion: Ensuring Efficiency in Hydraulic Systems

Common hydraulic fittings and standard connections are the unsung heroes of hydraulic systems. Their seamless collaboration ensures that fluid power is harnessed effectively across industries. Choosing the right fittings, adhering to standardization, and prioritizing maintenance all contribute to the longevity and reliability of these systems.

Post time: Aug-31-2023