In the world of hydraulic systems, choosing the right fittings is crucial for ensuring optimal performance and preventing leaks or system failures. Among the various fittings available, Code 62 hydraulic fittings stand out for their ability to handle high-pressure applications with exceptional reliability. In this article, we will delve into the world of Code 62 fittings, exploring their design, advantages, applications, and more.

What are Code 62 Hydraulic Fittings?

Code 62 hydraulic fittings are specifically engineered for high-pressure systems, providing a robust and leak-resistant connection between components. These fittings are designed to withstand significantly higher pressure ratings compared to standard fittings, making them ideal for heavy-duty applications where reliability is paramount. With their superior performance capabilities, Code 62 fittings offer peace of mind to operators in critical industries.

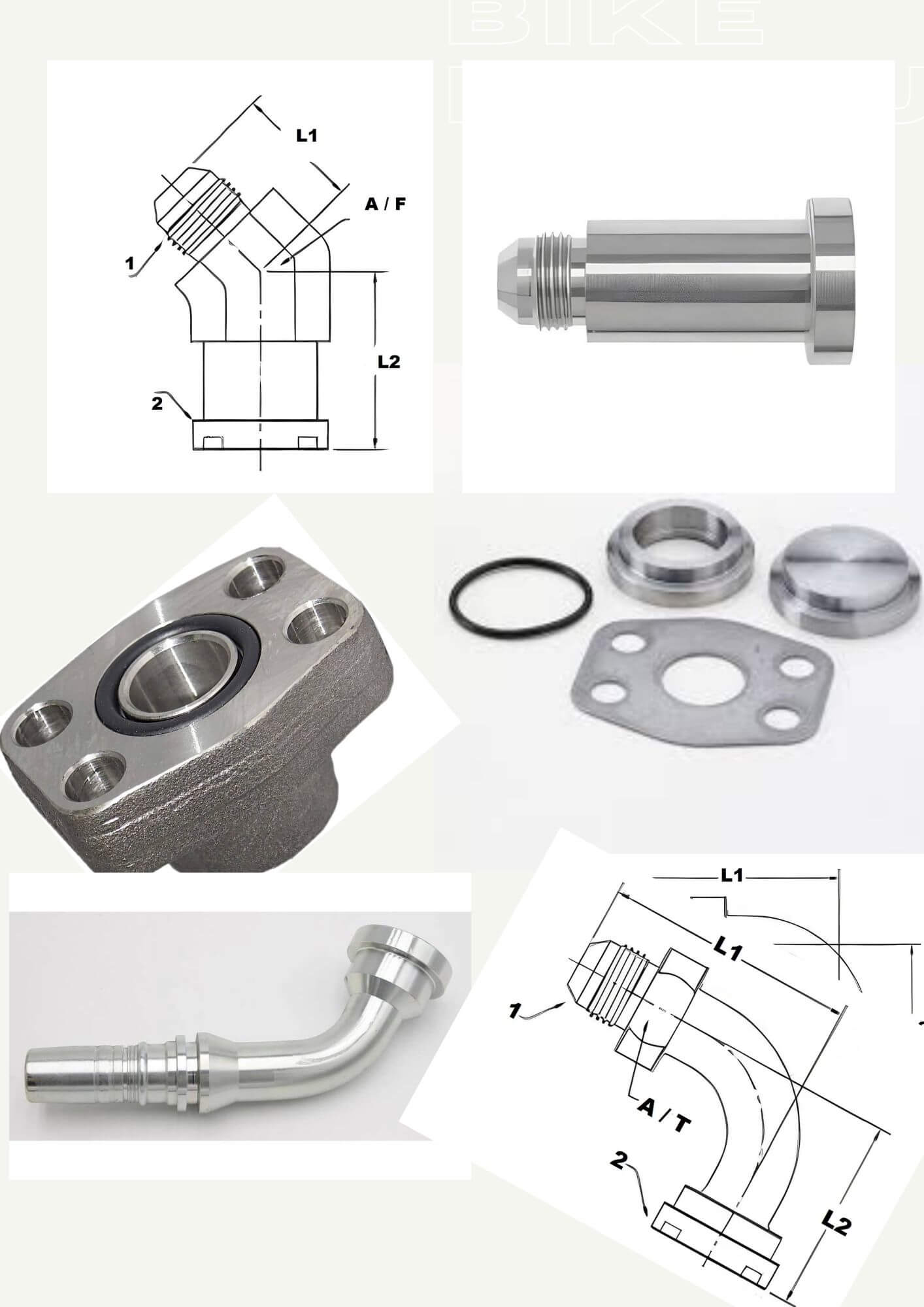

Several examples of Code 62 hydraulic fittings:

The Design and Construction of Code 62 Fittings

Code 62 fittings are constructed using high-quality steel alloys, ensuring strength and durability under extreme operating conditions. Additionally, these fittings often feature corrosion-resistant coatings or plating, protecting them from the harsh effects of fluids and environmental factors. This combination of robust materials and protective finishes enhances the longevity and reliability of Code 62 fittings.

Connection types and configurations vary for Code 62 fittings, but they commonly utilize flange connections with an O-ring seal design. This configuration ensures a secure and leak-free joint, even under high-pressure conditions. Threaded options are also available for applications where flange connections may not be suitable.

Code 62 vs. Other Hydraulic Fittings Standards

Different hydraulic systems may require different fitting standards, and it's essential to understand how Code 62 fittings compare to other common standards. When compared to Code 61 fittings, Code 62 fittings generally have higher pressure ratings and are specifically designed for more demanding applications. While interchangeability between Code 61 and Code 62 fittings is limited, understanding the specific requirements of your system will help determine the most appropriate choice.

Similarly, when comparing Code 62 fittings to Code 37 fittings, it becomes evident that they serve different connection methods and applications. Code 37 fittings typically use bite-type or flareless connections, whereas Code 62 fittings rely on flange connections. Understanding the nuances of each fitting type will help you select the most suitable option for your hydraulic system.

Applications and Industries Using Code 62 Fittings

Code 62 fittings find extensive use in industries that rely on heavy-duty machinery and equipment. Construction and mining operations benefit from the robust nature of Code 62 fittings, as they can handle the high-pressure demands of hydraulic systems in excavators, bulldozers, and other earth-moving machinery. The oil and gas industry also utilizes Code 62 fittings in drilling rigs, hydraulic fracturing equipment, and pipeline systems.

Moreover, Code 62 fittings play a vital role in industrial systems and processes. Manufacturing and automation applications, power generation plants, and marine and offshore operations all benefit from the reliability and leak resistance offered by Code 62 fittings. These fittings are well-suited for the demanding environments and critical operations found in these industries.

Installation and Maintenance of Code 62 Fittings

Proper installation is crucial for the effective performance of Code 62 fittings. Following manufacturer guidelines, including torque specifications, ensures the fittings are securely fastened. Additionally, careful alignment of flange connections and proper positioning of gaskets are essential to prevent leaks and maintain system integrity.

Regular inspection and maintenance practices are equally important for ensuring the longevity and reliability of Code 62 fittings. Routinely checking for leaks, especially at high-pressure joints, allows early detection and prompt resolution. Cleaning and lubrication recommendations should be followed to prevent contamination and reduce wear and tear on the fittings.

Code 62 Fittings Safety Considerations

Working with high-pressure hydraulic systems carries inherent risks, and safety should always be a top priority. Maintaining the integrity of Code 62 fittings is crucial for preventing accidents and equipment damage. Proper system design, adherence to pressure and temperature limitations, and utilizing appropriate safety devices all contribute to mitigating hazards associated with high-pressure systems.

Operators should also be aware of the correct handling and usage precautions when working with Code 62 fittings. Wearing suitable personal protective equipment (PPE) and receiving training and education on safe operating practices are vital for preventing injuries and ensuring compliance with safety regulations.

Selecting the Right Code 62 Fittings for Your Application

Choosing the most suitable Code 62 fittings for your hydraulic system involves considering various factors. Operating pressure and temperature requirements should be carefully assessed to ensure the fittings can withstand the specific demands of your system. Fluid compatibility is another crucial aspect, as different fluids can have varying effects on the materials used in Code 62 fittings.

Additionally, environmental conditions, such as exposure to harsh weather or corrosive substances, should be taken into account.

Consulting with experts and suppliers in the field is highly recommended when selecting Code 62 fittings. They can provide valuable insights, assist in customization options, and help evaluate the reliability and certifications of different fittings to ensure they meet your specific application needs.

Conclusion

Code 62 hydraulic fittings offer a reliable solution for high-pressure hydraulic systems, providing enhanced performance, durability, and leak resistance. Understanding their design, advantages, applications, and safety considerations is essential for making informed decisions when it comes to selecting the right fittings for your hydraulic system. By choosing Code 62 fittings, you can ensure the reliability and efficiency of your hydraulic operations, ultimately contributing to the success of your industry and business.

Post time: Jul-07-2023