Butt weld flanges are important in pipelines because they help fluids flow smoothly. They connect pipes together. These flanges are well-engineered and strong for connecting pipes in various industries. Let’s delve into the world of butt weld flanges and explore the myriad types of flanges that contribute to the efficiency of fluid systems.

What Are Butt Weld Flanges?

Butt weld flanges are welded directly to the end of a pipe, providing a strong and permanent connection. These flanges are well-known for being reliable and durable. They are often chosen for important applications that require strong structures. The welding process ensures a leak-proof connection, minimizing the risk of fluid leakage.

What Are Different Types of Flanges?

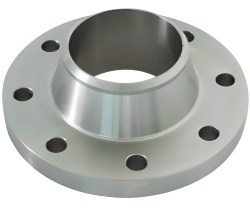

Weld Neck Flanges: Enhancing Structural Integrity

Weld neck flanges are characterized by their extended neck, providing additional support to the pipe. These flanges have a tapered hub that strengthens the connection. They are great for high-pressure use. This type of flange is widely used in industries where structural integrity is a priority.

Slip-On Flanges: Streamlining Installation

After sliding over the pipe, slip-on flanges are welded into position. These flanges are easy to install, so they are popular in applications that need efficiency and speed. The snug fit of slip-on flanges ensures a secure connection, minimizing the risk of misalignment.

Socket Weld Flanges: Ensuring Enhanced Flow

Socket weld flanges are designed with a recessed area to accommodate the pipe’s end. The pipe is inserted into the socket, and fillet welding is applied for a robust connection. This flange allows fluid to flow smoothly. It is good for applications that need a strong flow.

Threaded Flanges: Versatility in Connection

Threaded flanges feature threads on the bore, allowing them to be screwed onto the pipe. Threaded flanges are great for applications that need frequent maintenance or changes. Installing and removing them is simple.

Lap Joint Flanges: Accommodating Misalignment

Lap joint flanges are unique in their design, with a stub end that allows easy bolting to the connected pipe. The design of these flanges can adjust for small misalignments, making them suitable for flexible alignment.

Blind Flanges: Closing Off Connections

Blind flanges serve the crucial role of closing off the end of a pipe. This type of flange is employed when the end of the pipe needs to be sealed, preventing the flow of fluids. Blind flanges are often used when expansion or maintenance is expected in the future.

Orifice Flanges: Precision in Flow Measurement

Orifice flanges are made especially for applications involving flow metering. They feature a small hole or orifice that facilitates accurate measurement of fluid flow. This type of flange is essential in industries where precise control of fluid flow is paramount.

Conclusion

The world of butt weld flanges is vast and diverse, with each type of flange serving a unique purpose in fluid systems. Professionals in precise industries must understand flanges to be reliable and efficient.

Post time: Dec-29-2023