In hydraulic systems, ensuring secure and leak-free connections is crucial for efficient and reliable operation. When it comes to establishing connections through solid barriers, bulkhead fittings play a vital role.

In this article, we will explore the world of bulkhead fittings in hydraulic systems, discussing their types, components, working principles, benefits, applications, considerations for choosing, installation, maintenance, troubleshooting, and safety considerations.

Types of Bulkhead Fittings

➢ Standard Bulkhead Fittings

Standard bulkhead fittings provide a versatile solution for creating connections through solid barriers. They typically consist of a body, lock nut or compression ring, O-ring or gasket, and nut and ferrule. These fittings offer ease of installation and provide reliable sealing.

➢ Locknut Bulkhead Fittings

Locknut bulkhead fittings utilize a locknut mechanism to create a secure connection. The locknut ensures proper compression and sealing of the fitting against the barrier, making it suitable for applications with high vibration or external forces.

➢ Compression Bulkhead Fittings

Compression bulkhead fittings employ compression rings to create a tight and leak-free connection. They are often used when connecting hydraulic hoses or pipes through solid barriers, offering reliability and ease of assembly.

➢ Flanged Bulkhead Fittings

Flanged bulkhead fittings feature a flange that provides a robust connection. This type of fitting is commonly used in applications that require high-pressure sealing or where frequent disconnection and reconnection are required. Flanged bulkhead fittings offer durability and convenience.

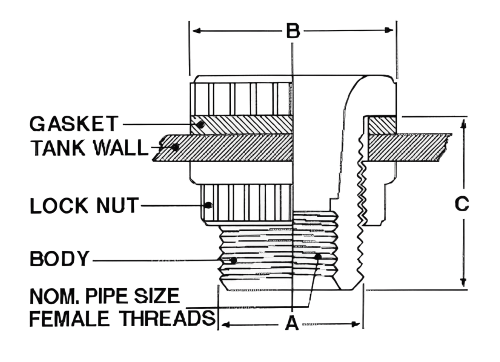

Components of Bulkhead Fittings

Bulkhead fittings consist of several key components that contribute to their functionality:

➢ Body

The body of a bulkhead fitting acts as the main structure, providing the connection point between two hydraulic components. It is designed to fit through a solid barrier and facilitate a secure connection.

➢ Lock Nut or Compression Ring

The lock nut or compression ring is an essential component that ensures a tight seal. In locknut bulkhead fittings, the locknut secures the fitting against the barrier, while compression bulkhead fittings utilize a compression ring to create a reliable seal.

➢ O-ring or Gasket

The O-ring or gasket is placed between the fitting and the barrier to prevent fluid leakage. It provides a sealing surface that is compressed when the fitting is tightened, ensuring a leak-free connection.

➢ Nut and Ferrule

The nut and ferrule work together to secure the connection. The nut is tightened onto the fitting, compressing the ferrule against the hose or pipe, creating a tight and reliable seal.

Working Principle of Bulkhead Fittings

Bulkhead fittings operate based on a solid barrier principle, ensuring secure and leak-free connections:

✅ Creating a Secure and Leak-Free Connection through a Solid Barrier

The primary purpose of a bulkhead fitting is to enable connections through a solid barrier, such as a wall or panel. By inserting the fitting through the barrier and tightening the components, a secure and leak-free connection is established.

✅ Utilizing Compression or Flanged Mechanisms for Tight Sealing

Depending on the type of bulkhead fitting, either a compression or flanged mechanism is employed to achieve a tight seal. Compression fittings utilize rings or locknuts to compress the O-ring or gasket, ensuring a reliable seal. Flanged fittings, on the other hand, rely on the flange to provide a robust connection and sealing surface.

Benefits of Bulkhead Fittings

Bulkhead fittings offer several benefits that make them valuable components in hydraulic systems:

✅ Facilitating Installation of Hydraulic Systems through Solid Barriers

Bulkhead fittings enable the installation of hydraulic components or systems through solid barriers, allowing for convenient routing of hoses or pipes. This feature simplifies the installation process and saves valuable space.

✅ Ensuring Leak-Free Connections in Challenging Environments

The reliable sealing provided by bulkhead fittings ensures leak-free connections even in challenging environments. Whether facing high pressures, vibrations, or external forces, bulkhead fittings maintain the integrity of the hydraulic system.

✅ Allowing for Easy Maintenance and Repairs without System Disassembly

Bulkhead fittings allow for easy maintenance and repairs without the need for system disassembly. By disconnecting the fitting components, servicing or replacing hydraulic components becomes more efficient, minimizing downtime.

Applications of Bulkhead Fittings

Bulkhead fittings find applications in various industries and hydraulic systems:

➢ Industrial Machinery and Equipment

Bulkhead fittings are commonly used in industrial machinery and equipment, where connections need to be established through solid barriers. They facilitate the efficient and reliable functioning of hydraulic systems in manufacturing processes.

➢ Automotive and Transportation Systems

Bulkhead fittings play a crucial role in automotive and transportation systems, where hydraulic connections are required through vehicle bodies or structural components. They provide secure and leak-free connections for braking systems, power steering, and more.

➢ Marine and Offshore Applications

In marine and offshore applications, bulkhead fittings are essential for establishing connections through vessel hulls or structural barriers. They ensure reliable and leak-free connections in hydraulic systems used in ships, offshore platforms, and subsea equipment.

➢ Hydraulic Power Units and Control Systems

Bulkhead fittings are widely utilized in hydraulic power units and control systems. They allow for secure connections through control panels, cabinets, or walls, facilitating the efficient and safe operation of hydraulic power units and control systems.

Considerations for Choosing Bulkhead Fittings

When selecting bulkhead fittings, certain factors should be considered:

✅ Size and Compatibility with Hydraulic Hoses or Pipes

Choose bulkhead fittings that are compatible with the size and type of hydraulic hoses or pipes used in your system. Ensuring a proper fit is essential for a secure and leak-free connection.

✅Pressure and Temperature Ratings

Consider the pressure and temperature requirements of your hydraulic system. Select bulkhead fittings that can withstand the specific operating conditions to maintain performance and safety.

✅ Material Selection Based on Application and Environment

The material used in bulkhead fittings should be chosen based on the application and environmental factors. Consider aspects such as corrosion resistance, durability, and compatibility with hydraulic fluids to ensure optimal performance.

Installation of Bulkhead Fittings

Proper installation is crucial for the optimal performance of bulkhead fittings. The following steps outline the installation process:

✅ Preparing the Bulkhead Surface

Ensure that the bulkhead surface is clean and free from any debris or contaminants that could compromise the connection. This step ensures a proper seal and secure fit.

✅ Inserting the Bulkhead Fitting and Tightening Components

Insert the bulkhead fitting through the prepared hole in the barrier. Tighten the components, such as the lock nut or compression ring, the O-ring or gasket, and the nut and ferrule, following the manufacturer’s specifications. This will create a secure and leak-free connection.

✅ Conducting Pressure Tests and Inspections

After installation, conduct pressure tests to verify the integrity of the connection. Inspect the fitting for any signs of leaks, damage, or improper sealing. Address any issues promptly to ensure the reliable operation of the hydraulic system.

Maintenance and Troubleshooting

Proper maintenance and troubleshooting practices contribute to the longevity and optimal performance of bulkhead fittings:

➢ Regular Inspections for Leaks or Damage

Periodically inspect bulkhead fittings for any signs of leaks, damage, or wear. Detecting and addressing issues early can prevent further damage and ensure a reliable connection.

➢ Replacing O-rings or Gaskets When Necessary

If O-rings or gaskets show signs of wear or damage, replace them promptly to maintain a proper seal. This step prevents fluid leakage and ensures the integrity of the hydraulic system.

➢ Addressing Connection Issues or Loosening of Components

If you notice any connection issues or loosening of components in bulkhead fittings, address them promptly. Tighten the components as needed to ensure a secure and leak-free connection.

Safety Considerations for Bulkhead Fittings

Working with hydraulic systems and bulkhead fittings requires adherence to proper safety precautions:

✅ Following Proper Installation Procedures

Ensure that individuals involved in the installation of bulkhead fittings follow the manufacturer’s recommended procedures. This ensures safe and proper installation, minimizing the risk of accidents or damage.

✅ Ensuring Compatibility and Secure Connections

Verify the compatibility of bulkhead fittings with the hydraulic hoses or pipes used in the system. Ensure that connections are secure and properly tightened to prevent leaks and system failure.

✅ Adhering to Industry Safety Guidelines

Follow industry safety guidelines and standards when working with hydraulic systems and bulkhead fittings. This includes wearing appropriate personal protective equipment and following proper safety protocols to minimize risks.

Conclusion

Bulkhead fittings are essential components in hydraulic systems, enabling secure connections through solid barriers. Their reliable sealing properties and ease of installation make them invaluable in various industries and applications. By understanding the types, components, working principles, benefits, applications, considerations for choosing, installation, maintenance, troubleshooting, and safety considerations associated with bulkhead fittings, you can maximize the performance and reliability of your hydraulic systems. Proper selection, installation, and maintenance of bulkhead fittings are key to ensuring leak-free connections and efficient hydraulic operations.

By following industry guidelines and taking necessary precautions, you can enhance safety and enjoy the benefits of secure and reliable hydraulic connections through solid barriers.

Post time: Jul-14-2023