1. Crafted from robust Stainless Steel or reliable Carbon Steel, these tube fittings ensure exceptional strength and durability for long-lasting performance.

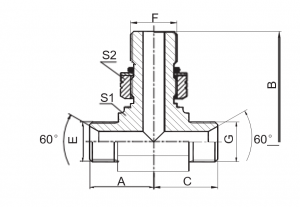

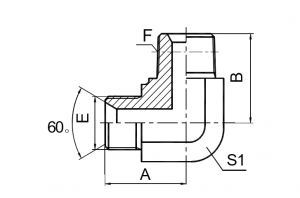

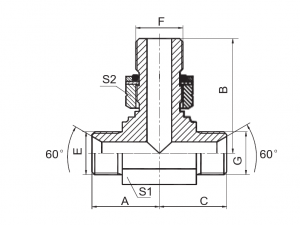

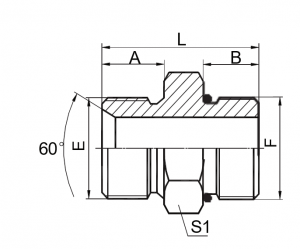

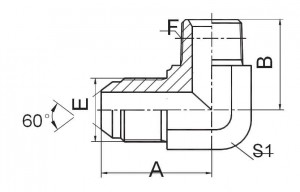

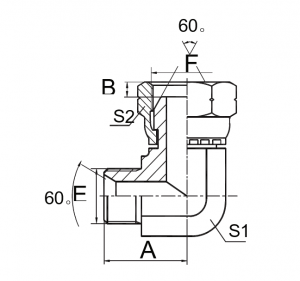

2. Choose from a variety of body types, including Straight, elbows (45 degrees and 90 degrees), allowing you to achieve the perfect fit and orientation for your specific application.

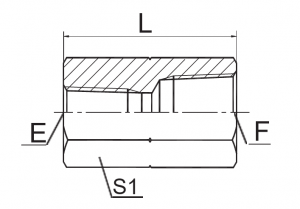

3. With compatibility across various thread systems like Metric, ISO Tapered, NPT, BSPP, BSPT, JIS, SAE, UNF, G, R, and JIC, these fittings offer seamless integration into different systems.

4. The tube fittings feature multiple connection surface options, such as Multi-seal, Flat, Flat O-Ring, and Cone Seat, ensuring leak-free and reliable connections, enhancing overall system performance.

5. Suitable for a diverse range of applications, these BSP Male 60°Seat / SAE O-Ring Boss L-Series ISO 11926-3 Branch Tees are the ideal choice for industries requiring versatile and dependable tube fittings.

|

PART NO.

|

THREAD | O-RING | DIMENSIONS | ||||||

| E | F | G | F | A | B | C | S1 | S2 | |

| SABOB-04OG | G1/4″X19 | 7/16″X20 | G1/4″X19 | 8.92X1.83 | 25 | 30.5 | 25 | 14 | 17 |

| SABOB-06-04-06OG | G3/8″X19 | 7/16″X20 | G3/8″X19 | 8.92X1.83 | 27.5 | 31.5 | 27.5 | 16 | 17 |

| SABOB-06OG | G3/8″X19 | 9/16″X18 | G3/8″X19 | 11.89X1.98 | 27.5 | 33.3 | 27.5 | 16 | 19 |

| SABOB-08-06-08OG | G1/2″X14 | 9/16″X18 | G1/2″X14 | 11.89X1.98 | 34.5 | 37 | 34.5 | 22 | 19 |

| SABOB-08OG | G1/2″X14 | 3/4″X16 | G1/2″X14 | 16.36X2.21 | 34.5 | 40 | 34.5 | 22 | 24 |

| SABOB-12-10-12OG | G3/4″X14 | 7/8″X14 | G3/4″X14 | 19.18X2.46 | 40 | 47 | 40 | 27 | 27 |

| SABOB-12OG | G3/4″X14 | 1.1/16″X12 | G3/4″X14 | 23.47X2.95 | 40 | 51 | 40 | 27 | 32 |

| SABOB-16-12-16OG | G1″X11 | 1.1/16″X12 | G1″X11 | 23.47X2.95 | 46 | 54.5 | 46 | 33 | 32 |

| SABOB-16OG | G1″X11 | 1.5/16″X12 | G1″X11 | 29.74X2.95 | 46 | 54.5 | 46 | 33 | 41 |

| Note: F end is connected with ISO 11926-1 port. | |||||||||

Crafted from robust Stainless Steel or reliable Carbon Steel, these tube fittings guarantee exceptional strength and durability, ensuring long-lasting and reliable performance.

You have the freedom to choose from a variety of body types, including Straight, Elbows (45 degrees and 90 degrees), allowing you to achieve the perfect fit and orientation for your specific application needs.

Our tube fittings boast compatibility across various thread systems, such as Metric, ISO Tapered, NPT, BSPP, BSPT, JIS, SAE, UNF, G, R, and JIC. This wide compatibility ensures seamless integration into different systems, providing flexibility and ease of use.

With multiple connection surface options available, including Multi-seal, Flat, Flat O-Ring, and Cone Seat, these fittings ensure leak-free and reliable connections. Such robust connections enhance overall system performance and contribute to a reliable and efficient workflow.

These BSP Male 60° Seat / SAE O-Ring Boss L-Series ISO 11926-3 Branch Tees are suitable for a diverse range of applications. Their versatility and dependability make them the ideal choice for industries requiring top-quality tube fittings.

Whether you need OEM or ODM orders, we are here to meet your requirements. We also offer optional logo printing or design services, allowing you to customize the fittings to your specific needs.

Our commitment to responsibility ensures the quality and service of our connector tube fittings. Our professional engineers and advanced equipment guarantee high-quality products, and we take pride in being one of the best hydraulic fitting factories.

For more information or to place an order, please don’t hesitate to contact us. We look forward to providing you with top-quality BSP Male 60° Seat / SAE O-Ring Boss L-Series ISO 11926-3 Branch Tee tube fittings for your hydraulic system needs.

-

BSP Male Double Use Fitting | Versatile Solutio...

-

BSP Male 60° Seat / BSP Male O-Ring Branch Tee ...

-

BSPT Female / BSP Female 60° Cone Fittings | Zi...

-

BSP Male Double Use Fitting for 60° Cone Seat /...

-

90° Elbow JIS Gas Male Fitting / 60° Cone / BSP...

-

Reliable 90° Elbow Fitting | BSP Male 60° Seat ...