1. British Parallel Pipe conforms to ISO 228-1, making it compatible with other British Pipe Standard fittings.

2. The thread flank angle is 55°, ensuring a secure and reliable seal for high-pressure applications.

3. The port conforms to ISO 1179, providing a standardized interface for hydraulic systems.

4. Parallel threads require an O-Ring, crush washer, gasket, or metal-to-metal seal between connections for a pressure-tight connection, preventing leaks and ensuring safety.

5. Available in 2 versions – parallel (BSPP) and tapered (BSPT).

|

PART# |

PORT THREAD SIZE |

WRENCH FLATS |

INTERFACE THREAD SIZE |

OVERALL LENGTH |

WEIGHT |

|

SEMA3/1/8ED** |

1/8 BSPP |

19 |

M16X2.0 |

1.77 |

0.15 |

|

SEMA3/1/4ED** |

1/4 BSPP |

19 |

M16X2.0 |

1.94 |

0.16 |

|

SEMA3/3/8ED** |

3/8 BSPP |

21 |

M16X2.0 |

1.94 |

0.16 |

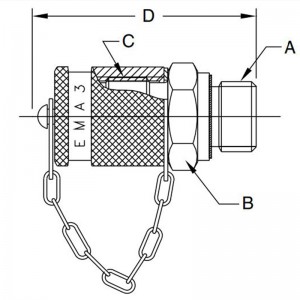

Our British Parallel Pipe is a popular choice among foreign threads, known for its versatility and reliability. It is available in two versions: parallel (BSPP) and tapered (BSPT). The thread flank angle for both versions is 55°, providing a secure and dependable seal for various hydraulic applications.

Conforming to the ISO 228-1 standard, our British Parallel Pipe ensures compatibility with other British Pipe Standard fittings. This standardization allows for easy integration and interchangeability within hydraulic systems, simplifying the selection and installation of components.

The port of our British Parallel Pipe complies with the ISO 1179 standard, providing a standardized interface for hydraulic connections. This facilitates seamless integration and enables the use of compatible components across different hydraulic systems.

For parallel threads, a pressure-tight connection requires the use of an O-Ring, crush washer, gasket, or a metal-to-metal seal between connections. This ensures a leak-free and secure joint, guaranteeing the integrity and safety of your hydraulic system.

It is important to note that our British Parallel Pipe is not interchangeable with SAE or NPT(F) threads. Each thread type has its own unique specifications and requirements. To avoid confusion, it is crucial to correctly identify and match the thread type when working with hydraulic connections.

At Sannke, we take pride in being a leading hydraulic fitting factory, dedicated to providing high-quality products. Contact us today to discover how our hydraulic fittings can enhance the performance and reliability of your hydraulic systems.