1. Its 45-degree angle ensures efficient directional changes, promoting optimal fluid flow throughout your system.

2. Choose from a range of protective finishes including zinc-plated, Zn-Ni-plated, Cr3, and Cr6-plated. These finishes not only add visual appeal but also provide exceptional corrosion resistance, ensuring longevity in challenging environments.

3. Craft the fitting to your specific needs with alternative materials such as stainless steel, carbon steel, and brass. This adaptability guarantees compatibility with a wide range of fluids and environments, catering to diverse industries.

4. Its meticulously designed seal technology ensures leak-proof connections, making it an ideal choice for critical fluid applications.

5. From its diverse finishes to material options, this fitting adheres to the highest standards of quality.

|

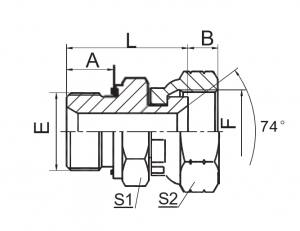

PART NO.

|

THREAD | O-RING | DIMENSIONS | ||||

| E | F | E | A | B | S1 | S2 | |

| S2F4-04 | 9/16X18 | 9/16X18 | O011 | 18.3 | 8.5 | 14 | 19 |

| S2F4-06 | 11/16″X16 | 11/16″X16 | O012 | 20.5 | 10 | 19 | 22 |

| S2F4-08 | 13/16″X16 | 13/16″X16 | O014 | 24 | 11 | 22 | 27 |

| S2F4-10 | 1″X14 | 1″X14 | O016 | 28 | 15 | 27 | 30 |

| S2F4-12 | 1.3/16″X12 | 1.3/16″X12 | O018 | 30.7 | 15 | 30 | 36 |

| S2F4-16 | 1.7/16″X12 | 1.7/16″X12 | O021 | 33 | 15 | 36 | 41 |

| S2F4-20 | 1.11/16″X12 | 1.11/16″X12 | O025 | 35.5 | 15 | 41 | 50 |

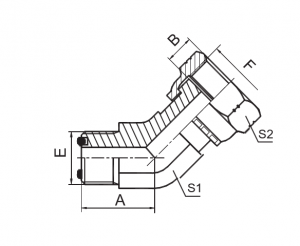

Elevate your fluid system’s efficiency with the precisely engineered 45° Elbow ORFS Male O-Ring / ORFS Female fitting. This fitting’s 45-degree angle is more than design—it’s a guarantee of efficient directional changes that foster optimal fluid flow throughout your system.

Delight in the freedom of choice with a range of protective finishes including zinc-plated, Zn-Ni-plated, Cr3, and Cr6-plated options. Beyond their visual allure, these finishes bolster the fitting’s longevity with exceptional corrosion resistance, ensuring performance remains intact even in the most challenging environments.

Craft the fitting to align seamlessly with your distinct requirements by choosing alternative materials such as stainless steel, carbon steel, and brass. This adaptability ensures compatibility across a wide spectrum of fluids and operating contexts, addressing the unique needs of diverse industries.

Experience confidence in leak-proof connections, facilitated by meticulously designed seal technology. This fitting is more than a component—it’s a solution tailored for critical fluid applications where reliability is non-negotiable.

From the spectrum of finishes to the myriad of material options, this fitting stands as a testament to the highest standards of quality. Every facet is crafted with precision that meets and surpasses industry benchmarks.

Unearth the pinnacle of hydraulic fitting craftsmanship through Sannke, an emblem of distinction within hydraulic fitting factories. For inquiries and access to hydraulic solutions customized for your specific needs, don’t hesitate to connect with us. Your journey towards optimized fluid system performance commences with Sannke.

-

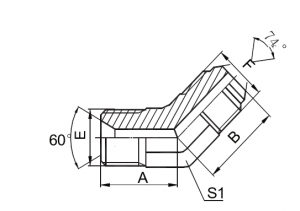

45° BSP Male 60° Seat / JIC Male 74° Cone Adapt...

-

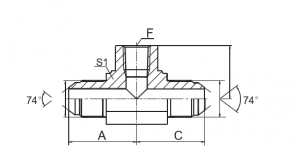

JIC Male / BSPT Female / JIC Male Fittings | Re...

-

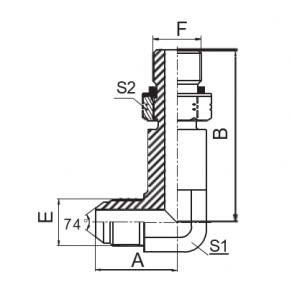

90° JIC Male / Extra Long SAE 74° O-Ring Boss |...

-

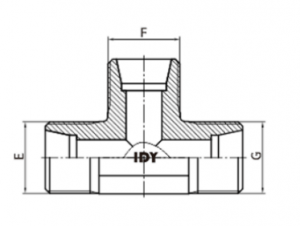

Barrel Tee BSP Thread Adjustable Stud Ends With...

-

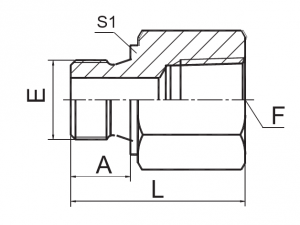

BSP Male Captive Seal / JIC Female 74° Seat | F...

-

Metric Male with Bonded Seal / NPT Female | Ver...