Hydraulic systems run on seriously high pressure, so even the tiniest leak can turn into a big, messy, and expensive problem. That’s why good sealing isn’t optional… it’s essential. And when it comes to keeping hydraulic fluid right where it belongs, nothing gets the job done like an O-ring.

These little rubber flex, seal, and hold strong against pressure, vibration, and whatever else your machine throws at them.

In this article, we’ll dive into the top 10 types of hydraulic fittings with O-rings, what they are, how they work, and why they’re the go-to choice for leak-free performance across industries.

Let’s keep those systems running tight!

What Are Hydraulic Fittings with O-Rings?

Hydraulic fittings with O-rings are connectors designed with a built-in elastomer ring that compresses when tightened, creating a tight and reliable seal. Unlike metal-to-metal fittings, which rely solely on precision machining, O-rings provide a softer sealing surface that adapts to minor imperfections.

How O-rings improve reliability

O-rings enhance reliability by:

1. Providing uniform sealing pressure

2. Compensating for minor surface irregularities

3. Withstanding vibration, temperature changes, and pressure spikes

This makes them especially effective in dynamic or high-pressure environments.

Common O-ring materials

O-rings are produced from several elastomers, including:

➡️ NBR (Nitrile): The most common, ideal for petroleum-based hydraulic fluids

➡️ Viton (FKM): High-temperature and chemical-resistant

➡️ EPDM: Excellent for water-based fluids

Choosing the right material ensures optimal sealing and extended service life.

Advantages over metal-to-metal sealing

O-ring fittings offer:

1. Better resistance to vibration

2. Superior leak prevention

3. Easier installation

4. Longer-lasting seals

These advantages make O-ring fittings the preferred option for most modern hydraulic systems.

Benefits of Using O-Ring Hydraulic Fittings

Enhanced leak protection

The elastomeric seal ensures a tight connection even when system pressure fluctuates.

Vibration resistance

O-rings absorb shock and movement, reducing the risk of loosening or leakage.

High-pressure performance

They maintain seal integrity even in systems exceeding thousands of PSI.

Easy installation and maintenance

O-ring fittings require less torque and less precision than metal-to-metal types.

Fluid compatibility

With various material options, O-rings can be matched to almost any hydraulic fluid.

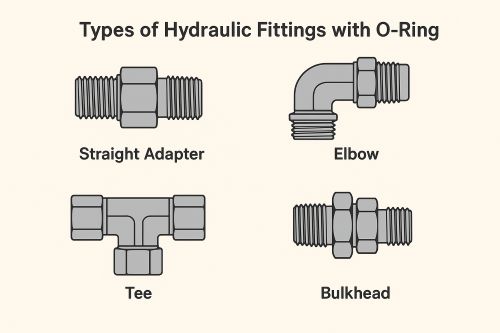

Top 10 Types of Hydraulic Fittings with O-Ring for Leak-Free Performance

1. O-Ring Face Seal (ORFS) Fittings

ORFS fittings feature a flat face with an embedded O-ring that forms the sealing surface when joined.

Best applications:

➡️ Heavy machinery

➡️ Agriculture equipment

➡️ High-pressure hydraulic lines

Why they excel:

Their design virtually eliminates leaks caused by vibration or over-tightening, making them one of the most reliable O-ring fittings available.

2. O-Ring Boss (ORB) Fittings

ORB fittings use straight threads with an O-ring seated in a groove to create a fluid-tight seal.

Common uses:

➡️ Hydraulic pumps

➡️ Cylinders

➡️ Control valves

Key benefit:

ORB fittings allow for angular adjustment before tightening, making installation easier and more flexible.

3. SAE Straight Thread O-Ring Fittings

These fittings follow SAE standards and use straight threads paired with an O-ring to seal at the port interface. They are ideal for any equipment using SAE O-ring ports.

Common applications:

1. Construction equipment

2. Industrial hydraulic systems

3. Mobile machinery

4. Flareless Bite-Type O-Ring Fittings

These fittings feature a ferrule that “bites” into the tubing when tightened, eliminating the need for flaring.

Industries:

1. Mining

2. Construction

3. Forestry machinery

Strength and performance:

They offer high structural integrity and reliable sealing under extreme pressure.

5. JIC-to-ORB Adapter Fittings

These hybrids use JIC threads but integrate an O-ring boss for sealing.

Use cases:

1. Retrofits

2. Custom hydraulic assemblies

3. Systems transitioning between fitting styles

Leak prevention:

The added O-ring provides superior sealing compared to standard JIC metal-to-metal seats.

6. Metric O-Ring Hydraulic Fittings

These fittings are manufactured according to DIN and ISO specifications.

Common in:

1. European equipment

2. Asian machinery

3. International hydraulic systems

Sealing performance:

They deliver reliable sealing while meeting global engineering requirements.

7. BSPP O-Ring Port Fittings

British Standard Parallel Pipe fittings that use parallel threading and an O-ring for sealing.

Comparison to BSPT:

Unlike BSPT tapered threads, BSPP uses the O-ring instead of thread deformation to seal.

Industries:

1. Oil & gas

2. Marine

3. Heavy industrial applications

8. Flange Connectors with O-Ring Seal

Flanges use an O-ring groove on the mating surface, tightened by bolts to form a strong, reliable seal.

Ideal for:

➡️ Ultra-high-pressure systems

➡️ Large-diameter hydraulic lines

Code 61 vs. Code 62

-

Code 61: Standard pressure

-

Code 62: Higher pressure rating

9. Swivel O-Ring Hydraulic Fittings

Designed to rotate during movement, preventing hoses from twisting or kinking. The O-ring maintains a seal even during rotation, ensuring no fluid escapes.

Applications:

➡️ Articulating boom equipment

➡️ Rotating robotic arms

➡️ Mobile hydraulic machinery

10. O-Ring Plug and Cap Fittings

These fittings temporarily or permanently seal unused ports. They prevent contamination, fluid loss, and damage during system shutdowns or transport.

Types:

➡️ Threaded plugs

➡️ Flat-faced caps

➡️ Pressure-resistant designs

How to Select the Right O-Ring Hydraulic Fitting

Here are the key considerations:

1. Pressure rating: Ensure the fitting can withstand system pressure

2. Fluid type: Match the O-ring material to hydraulic fluid

3. Thread compatibility: Verify SAE, metric, BSPP, or ORB requirements

Choosing the correct O-ring

Consider:

1. Material compatibility

2. Temperature range

3. Size based on groove and port dimensions

Mistakes to avoid

1. Using incompatible O-ring materials

2. Over-tightening fittings

3. Mixing thread standards

Maintenance Tips for O-Ring Hydraulic Fittings

Inspection

Regularly check for:

➡️ Cracks

➡️ Flattening

➡️ Hardening

➡️ Cuts or abrasions

Lubrication & installation

Use compatible lubricants and make sure fittings are aligned before tightening.

Replacement frequency

Replace O-rings at the first sign of wear or during scheduled maintenance cycles.

Signs of failure

Watch for:

1. Drips or seepage

2. Pressure loss

3. Unusual vibration

4. Air in the system

Address issues immediately to prevent larger failures.

Conclusion

Hydraulic fittings with O-rings offer unmatched leak prevention, durability, and performance under high pressure. The top 10 types listed in this guide each serve unique roles, ensuring you can find the perfect solution for your hydraulic system.

By choosing the right O-ring material, maintaining your fittings properly, and understanding the advantages of each type, you can significantly improve your equipment’s reliability and efficiency.

If you found this guide helpful, consider subscribing to more hydraulic insights, contacting us for high-quality hydraulic parts, or exploring our other technical resources.

Post time: Nov-27-2025