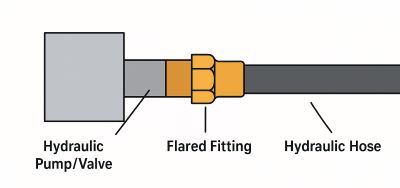

Hydraulic systems power everything from construction machinery to manufacturing equipment, and their reliability depends heavily on secure, leak-free connections. One of the most dependable ways to achieve these connections is through flaring, a technique that shapes the end of a tube so it can connect tightly to a fitting.

In this guide, we’ll explore the different types of flaring in hydraulic systems, how each type works, and where they are most commonly used.

What Is Flaring in Hydraulic Systems?

Flaring is a process that reshapes the end of a metal tube, typically steel, stainless steel, copper, or aluminum, into a conical or rounded shape. This modified end forms a tight, pressure-resistant seal when joined with the correct fitting.

A proper flare is essential because hydraulic systems operate under high pressure. A poorly formed flare can lead to leaks, equipment damage, or even system failure.

The basic flaring process includes:

1. Cutting the tube cleanly

2. Deburring the inside and outside edges

3. Forming the flare with a flaring tool

4. Inspecting for smoothness, symmetry, and the correct angle

Why Flaring Is Important

Flaring plays a crucial role in hydraulic reliability. It offers several benefits:

1. Leak-free sealing: Prevents fluid loss and pressure drops

2. High-pressure tolerance: Suitable for heavy-duty machinery

3. Compatibility: Works with standard hydraulic fittings (JIC, SAE, etc.)

4. Safety and durability: Reduces the risk of hose blowouts or failures

5. Vibration resistance: Especially important in mobile equipment and vehicles

Types of Flaring in Hydraulic Systems

Different hydraulic applications require different flare types. Here are the most common ones used in industry today.

|

Flare Type |

Description |

Common Uses |

Advantages |

Limitations |

|

Single 45° Flare |

Simple conical flare formed at 45 degrees |

Light-duty hydraulics, plumbing, older automotive lines |

Easy to produce, general-purpose |

Not suitable for high-pressure or high-vibration environments |

|

Double 45° Flare |

Tubing edge is folded inward before flaring for added strength |

Automotive brake lines, fuel systems, areas with vibration |

Stronger and longer-lasting than single flares, better sealing |

More steps required; not used in high-pressure industrial hydraulics |

|

High-pressure flare used with standardized JIC fittings |

Industrial hydraulics, construction equipment, agriculture machinery |

Excellent pressure resistance, widely standardized, durable |

Requires precise tooling; angle cannot be mixed with 45° |

|

|

ISO/DIN Bubble Flare |

Forms a rounded “bubble” shape before tightening |

European vehicles, light-duty hydraulic systems, vibration-heavy setups |

Good sealing, works with metric lines, vibration resistant |

Limited to specific metric fittings and standards |

|

Flare is shaped inward to mate with compression fittings |

Automotive brakes and fuel lines, low-pressure hydraulics |

Easy assembly, secure connection |

Not suitable for high-pressure environments |

|

|

Special/Custom Flares |

Proprietary or application-specific flare shapes |

Aerospace, high-pressure industrial systems, specialized machinery |

High precision, designed for extreme conditions |

Requires specialized machines; not interchangeable |

How Hydraulic Flaring Tools Work

The quality of a flare often depends on the tools used. Here are the main types:

|

Tool Type |

Description |

Best For |

Key Advantages |

Limitations |

|

Manual Flaring Tools |

Hand-operated tools that use mechanical force to form flares |

Small-scale work, field repairs, soft metals like copper |

Low cost, portable, simple to use |

Requires operator skill; less consistent results; slower for heavy-duty materials |

|

Hydraulic Flaring Tools |

Use hydraulic pressure to form accurate, consistent flares |

Frequent use, steel/stainless steel tubing, industrial applications |

Faster, more precise, handles tougher materials easily |

More expensive; bulkier than manual tools |

|

Automatic/Electric Flaring Machines |

Motorized or fully automated machines for high-precision flaring |

Manufacturing, aerospace, large-scale production |

Maximum accuracy, fast cycle times, ideal for high-volume output |

Highest cost; requires power and dedicated workspace |

Where Each Type of Flare Is Used

1. Industrial Hydraulics

-

Presses

-

Injection molding machines

-

Heavy-duty hydraulic lines

2. Automotive and Transportation

-

Brake and fuel lines

-

Power steering systems

3. Construction and Agriculture

-

Excavators

-

Loaders

-

Tractors

4. HVAC & Refrigeration

-

Copper tubing

-

Refrigerant lines

5. Aerospace and Marine

-

High-vibration, high-precision systems

-

Corrosion-resistant lines

Choosing the Right Type of Flare

When selecting a flare type, consider:

1. Pressure rating requirements

2. Type of fluid being used

3. Vibration levels

4. Compatibility with fittings

5. Material of the tubing

Matching the flare to the correct fitting is essential because mixing angles (like 37° and 45°) will lead to immediate failure.

Common Flaring Mistakes to Avoid

1. Over-flaring or under-flaring

2. Using the wrong flare angle

3. Leaving burrs or sharp edges

4. Using incompatible fittings

5. Not checking the finished flare for cracks

Taking the time to form and inspect each flare saves time and prevents costly hydraulic failures.

Conclusion

Flaring is a small but essential part of hydraulic system design. Whether you’re working with 37° JIC flares, double flares, bubble flares, or specialized hydraulic flare types, choosing the right method ensures a secure, leak-free, and long-lasting connection.

Understanding how different types of hydraulic flaring work, and where they’re used, helps technicians, engineers, and mechanics create safer and more reliable hydraulic systems.

Post time: Dec-09-2025