Hydraulic systems are the lifeblood of modern industrial operations, powering everything from heavy machinery to precision control systems. These systems rely on a network of pipes and fittings that must withstand immense pressure, temperature fluctuations, and corrosive fluids. For this reason, durable and high-quality fittings are essential to ensure performance, safety, and longevity.

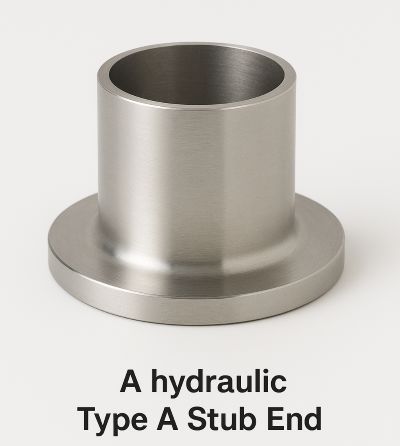

Among the many components that make up a hydraulic piping system, the Type A Stub End stands out as a crucial element. When manufactured from stainless steel, it provides the ideal combination of corrosion resistance, strength, and ease of maintenance, all vital in demanding hydraulic applications. Designed and standardized according to ASME, ANSI, MSS, and ASTM guidelines, stainless steel Type A Stub Ends offer compatibility and reliability for a wide range of industrial environments.

What Is a Type A Stub End?

A stub end is a short length of pipe with one flared end that is used in conjunction with a Lap Joint Flange to connect sections of piping. Instead of welding a flange directly to the pipe, the stub end provides a separable connection, allowing easy disassembly without cutting or re-welding.

The Type A Stub End features a machined face and a bevel that fits perfectly against a Lap Joint Flange, ensuring a secure and leak-free seal. It’s commonly used in systems where frequent dismantling or inspection is required.

Difference Between Stub End Types:

➡️ Type A: Designed for use with Lap Joint Flanges; the hub thickness matches the flange for smooth alignment.

➡️ Type B: Used with Slip-On Flanges; slightly different dimensions and a less polished facing.

➡️ Type C: A versatile option that can be used with either Lap Joint or Slip-On Flanges, often without a polished face.

Common manufacturing standards include ASME B16.9, MSS SP-43, and ASTM A403, which define dimensions, tolerances, and material properties.

Why Stainless Steel Is the Ideal Material

1. Corrosion Resistance:

Hydraulic fluids can be corrosive, especially in systems exposed to saltwater, chemicals, or harsh environments. Stainless steel resists oxidation and corrosion, ensuring long-term reliability.

2. Strength and Durability:

Hydraulic systems often operate under high pressure and temperature variations. Stainless steel maintains structural integrity under these stresses, reducing the risk of cracks or deformation.

3. Low Maintenance:

Once installed, stainless steel components require minimal upkeep. Their smooth surface resists buildup and allows easy cleaning, extending service life.

4. Recyclability and Sustainability:

Stainless steel is 100% recyclable, making it an environmentally responsible choice for industries seeking sustainable solutions.

Role of Stub Ends in Hydraulic Systems

Stub ends play a pivotal role in enhancing flexibility and maintainability within hydraulic networks. By pairing with Lap Joint Flanges, they allow easy pipe alignment and quick disassembly, ideal for systems requiring periodic inspection, cleaning, or modification.

Key contributions include:

1. Leak prevention through precise face alignment.

2. Pressure stability under fluctuating hydraulic loads.

3. Ease of reconfiguration, especially in modular hydraulic lines.

4. Compatibility with different flange types and pipe schedules.

Key Benefits of Stainless Steel Type A Stub Ends

1. Easy Installation and Alignment: The design simplifies assembly and ensures accurate positioning.

2. Cost-Effective Alternative: Eliminates the need for full-welded flanges, saving both material and labor costs.

3. Ideal for Maintenance-Heavy Systems: Perfect for hydraulic lines requiring frequent inspection or cleaning.

4. Excellent Performance: Maintains strength and sealing integrity in high-pressure and corrosive environments.

Common Applications

Stainless steel Type A stub ends are widely used in:

➡️ Industrial hydraulic systems and power plants.

➡️ Oil and gas transmission and refining pipelines.

➡️ Chemical processing and petrochemical facilities.

➡️ Marine and offshore installations, where corrosion resistance is critical.

➡️ Food and pharmaceutical production lines that demand hygiene and cleanability.

Manufacturing and Quality Standards

Stub ends can be either forged or machined from seamless pipe sections, ensuring dimensional accuracy and surface finish. Quality control measures are essential to meet industry requirements.

Common standards and specifications include:

➡️ ASME B16.9 – Factory-made wrought fittings.

➡️ MSS SP-43 – Butt-welding fittings for low-pressure applications.

➡️ ASTM A403 – Standard specification for stainless steel wrought fittings.

Quality assurance typically involves:

➡️ Dimensional inspection to verify conformity.

➡️ Hydrostatic testing to ensure pressure integrity.

➡️ Surface finish checks to guarantee smooth sealing surfaces.

Choosing the Right Stub End for Your Hydraulic System

Selecting the appropriate stub end requires attention to detail. Key factors include:

➡️ Material grade (e.g., 304, 316, or duplex stainless steel) for corrosion and strength requirements.

➡️ Size and wall thickness to match pipe dimensions and pressure ratings.

➡️ Flange compatibility to ensure a secure fit.

➡️ Pipe schedule and system pressure class alignment to maintain safety and performance.

Always source from a reputable manufacturer or supplier that provides certified materials and documented testing.

Maintenance and Longevity Tips

To maximize the lifespan of your stainless steel Type A stub ends:

➡️ Conduct routine inspections to identify wear or corrosion.

➡️ Clean regularly using non-abrasive methods to maintain surface integrity.

➡️ Avoid mechanical damage during installation or handling.

➡️ Replace fittings that show signs of pitting, erosion, or deformation to prevent leaks and maintain system efficiency.

Find useful resources here ⬇️⬇️⬇️

Hydraulic Threaded Brass Nipple for High-Pressure Applications

ASME B16.5 Ring Type Joint Flanges: Specifications, Materials, and Dimensions

Hydraulic Bell Reducer Pipe Fitting vs. Standard Reducer Pipe Fitting [Key Differences]

Conclusion

In hydraulic systems where reliability and performance are non-negotiable, stainless steel Type A stub ends offer a proven solution. Their combination of corrosion resistance, strength, and easy maintenance ensures long-term dependability in even the most demanding environments.

By adhering to recognized standards and selecting quality materials, engineers and system designers can achieve a balance of efficiency, safety, and cost-effectiveness. For optimal results, always consult with trusted experts or suppliers to ensure the right specifications for your application.

Post time: Oct-13-2025