Hydraulic systems rely on precise, high-pressure connections to operate safely and efficiently. One small but critical component that often goes unnoticed is the swivel joint. In hydraulic pipe fittings, swivel joints play a key role in improving flexibility, reducing stress, and preventing leaks.

Understanding what swivel joints are and why they matter can help engineers, technicians, and buyers make better decisions when designing or maintaining hydraulic systems.

What Are Swivel Joints?

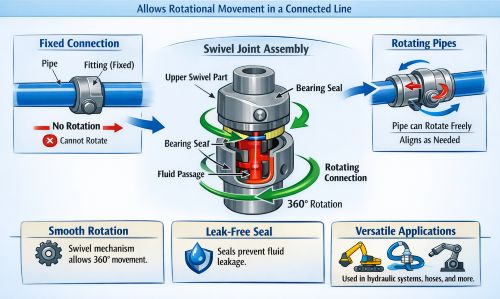

Swivel joints are specialized hydraulic fittings designed to allow rotation between connected components without interrupting fluid flow. Unlike standard fixed fittings, swivel joints enable movement, making them ideal for applications where pipes or hoses need to rotate, shift, or align during installation or operation.

A typical swivel joint consists of a rotating body, a stationary body, and an internal sealing system. This design allows the joint to turn freely while maintaining a secure, leak-free connection under pressure.

How Swivel Joints Work

Swivel joints work by allowing controlled rotational movement between two connected parts. Internal seals, such as O-rings, ball seals, or metal-to-metal seals, ensure that hydraulic fluid remains contained even as the joint rotates.

The rotation helps absorb movement caused by vibration, thermal expansion, pressure changes, or mechanical motion. By reducing torsional stress, swivel joints help protect pipes, hoses, and other hydraulic components from premature wear or failure.

Types of Swivel Joints Used in Hydraulic Pipe Fittings

There are several types of swivel joints used in hydraulic applications, each designed for specific operating conditions:

1. Single-plane swivel joints, which allow rotation in one direction

2. Multi-plane swivel joints, offering movement in multiple directions

3. Inline swivel joints, commonly used in straight pipe connections

4. Elbow or angled swivel joints, useful for tight spaces and directional changes

5. High-pressure swivel joints, engineered for demanding hydraulic environments

Selecting the right type depends on system pressure, movement requirements, and installation constraints.

Key Benefits of Swivel Joints in Hydraulic Systems

Swivel joints offer several important advantages in hydraulic pipe fittings:

1. Reduced stress on pipes and fittings, minimizing fatigue and cracking

2. Easier installation, as alignment does not need to be perfect

3. Improved system flexibility, especially in dynamic or mobile equipment

4. Extended component lifespan, lowering replacement and maintenance costs

By allowing controlled movement, swivel joints help hydraulic systems operate more smoothly and reliably.

Common Applications of Swivel Joints

Swivel joints are widely used across many industries, including:

➡️ Construction and heavy equipment

➡️ Industrial manufacturing machinery

➡️ Oil and gas processing systems

➡️ Marine and offshore equipment

➡️ Agricultural and mobile hydraulic systems

Any application involving movement, vibration, or frequent maintenance can benefit from the use of swivel joints.

Why Swivel Joints Matter in Hydraulic Pipe Fittings

In high-pressure hydraulic systems, even small misalignments can lead to leaks, seal damage, or fitting failure. Swivel joints help prevent these issues by accommodating movement and reducing mechanical stress.

They also improve safety by lowering the risk of sudden hose or pipe failures, which can be dangerous and costly. Over time, swivel joints contribute to lower downtime, improved system efficiency, and more predictable maintenance schedules.

Factors to Consider When Choosing a Swivel Joint

When selecting a swivel joint for hydraulic pipe fittings, several factors should be evaluated:

1. Pressure rating to match or exceed system requirements

2. Choosing materials like stainless steel or carbon steel

3. Seal type and compatibility with hydraulic fluids

4. Thread type, size, and industry standards compliance

Choosing the correct swivel joint ensures reliable performance and long-term durability.

Installation and Maintenance Best Practices

Proper installation is essential for swivel joint performance. Always follow manufacturer torque specifications and avoid over-tightening, which can damage seals. Ensure the joint is aligned correctly and free from contamination during installation.

Regular inspection for leaks, wear, or restricted movement can help identify issues early. Proper maintenance extends the service life of swivel joints and keeps hydraulic systems running efficiently.

Conclusion

Swivel joints may be small components, but their impact on hydraulic pipe fittings is significant. By allowing rotation, reducing stress, and preventing leaks, swivel joints improve system reliability, safety, and performance.

Whether you are designing a new hydraulic system or upgrading an existing one, understanding the role of swivel joints and selecting the right type can make a measurable difference in long-term operation and maintenance success.

Post time: Feb-09-2026