Hydraulic systems are the backbone of countless industries, powering everything from heavy machinery to precision aerospace equipment. At the heart of these systems are hydraulic fluid fittings, components that connect hoses, tubes, and pipes while ensuring a leak-free, efficient flow of hydraulic fluid. Without the right fittings, even the most advanced hydraulic system can suffer from inefficiency, leaks, and premature wear.

One of the most widely used fitting types is the right-angle (90-degree) hydraulic fitting. Known for its space-saving design and ability to redirect fluid flow, this component plays a crucial role in maintaining efficiency and reliability.

This guide will help you understand what right-angle fittings are, where they are used, and how to choose the right one for your hydraulic system.

What Are Right-Angle Hydraulic Fluid Fittings?

Right-angle hydraulic fittings, often called 90-degree elbow fittings, are connectors designed to change the direction of hydraulic fluid flow at a right angle.

➡️ Straight fittings connect components in a direct line.

➡️ Tee fittings split flow into three directions.

➡️ Right-angle fittings redirect flow at a sharp 90-degree turn, reducing hose stress and saving space.

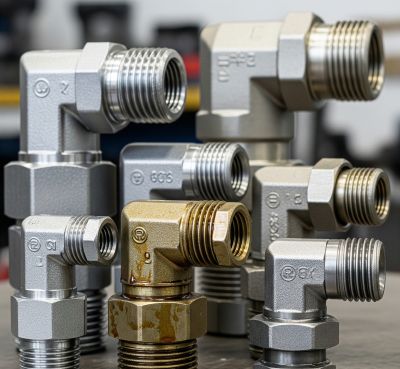

These fittings are manufactured in various materials depending on application needs:

➡️ Carbon steel – durable and suitable for high-pressure systems.

➡️ Stainless steel – corrosion-resistant, ideal for marine and offshore use.

➡️ Brass – commonly used in lower-pressure applications with excellent machinability.

Why Use Right-Angle Fittings in Hydraulic Systems?

Right-angle fittings provide several advantages that make them essential in compact or complex hydraulic layouts:

➡️ Space-saving design – Perfect for installations with limited room.

➡️ Smooth redirection of fluid flow – Prevents hose kinking and ensures consistent performance.

➡️ Improved efficiency – Helps streamline fluid paths in intricate hydraulic systems.

➡️ Reliability – Properly installed right-angle fittings minimize leaks and extend system life.

Types of Right-Angle Hydraulic Fittings

Hydraulic systems demand different types of 90-degree fittings to suit specific needs:

➡️ 90-Degree Elbow Fittings – Standard connectors for redirecting fluid at a right angle.

➡️ Swivel Elbows – Allow rotational movement while keeping a tight seal, reducing hose stress.

➡️ Adapter Elbows – Used to connect different thread types or sizes (e.g., BSP to NPT).

➡️ Custom or Heavy-Duty Right-Angle Fittings – Designed for extreme pressure or specialized requirements.

Key Applications of Right-Angle Hydraulic Fluid Fittings

Right-angle fittings are found in a wide range of industries, including:

➡️ Construction machinery – Excavators, loaders, cranes.

➡️ Agricultural equipment – Tractors, harvesters, irrigation systems.

➡️ Industrial hydraulic systems – Manufacturing plants, automation systems.

➡️ Automotive and aerospace systems – Power steering, braking systems, landing gear.

➡️ Marine and offshore applications – Ships, drilling platforms, and underwater equipment.

Factors to Consider When Choosing Right-Angle Fittings

Selecting the right fitting ensures safety, efficiency, and long service life. Key factors include:

➡️ Pressure rating – Match the fitting to your system’s operating pressure.

➡️ Material durability – Choose materials resistant to corrosion and wear.

➡️ Size and thread standards – Common standards include BSP, NPT, JIC, and ORFS.

➡️ Temperature tolerance – Ensure the fitting can withstand system heat ranges.

➡️ Ease of installation – Opt for fittings that simplify maintenance and replacement.

Benefits of Using Right-Angle Hydraulic Fittings

Using right-angle fittings in your system brings multiple advantages:

➡️ More efficient system layouts in confined spaces.

➡️ Reduced hose damage and leak risks.

➡️ Optimized fluid flow control.

➡️ Increased lifespan of the hydraulic system overall.

Installation and Maintenance Tips

To get the best performance, follow these guidelines:

➡️ Proper alignment – Prevents unnecessary stress on hoses.

➡️ Use correct sealing methods – Apply O-rings or thread sealants when needed.

➡️ Inspect regularly – Look for leaks, corrosion, or wear.

➡️ Replace worn fittings promptly – Avoid costly system failures.

Common Mistakes to Avoid

When dealing with hydraulic fittings, avoid these pitfalls:

➡️ Selecting the wrong thread type or size.

➡️ Over-tightening fittings, which can damage threads and seals.

➡️ Mixing incompatible materials.

➡️ Ignoring system pressure and temperature ratings.

FAQs

Q1: What is the difference between a 90-degree hydraulic fitting and a swivel fitting?

A 90-degree fitting redirects fluid flow at a right angle, while a swivel fitting adds the ability to rotate, reducing hose stress.

Q2: Can right-angle fittings handle high-pressure applications?

Yes, when made from suitable materials like carbon or stainless steel and rated for the system’s pressure.

Q3: How do I know which material is best for my hydraulic system?

Consider your environment: stainless steel for corrosion-prone areas, carbon steel for high-pressure, and brass for lighter-duty systems.

Q4: Are right-angle fittings reusable?

Some are reusable if not damaged, but it’s best practice to replace fittings when signs of wear appear.

Q5: What standards should I check before buying a hydraulic fitting?

Look for thread and connection standards like BSP, NPT, JIC, or ORFS to ensure compatibility.

Conclusion

Right-angle hydraulic fluid fittings may seem like small components, but they play a big role in system performance, reliability, and safety. By choosing the right type, material, and size, you ensure smoother fluid flow, reduced leaks, and longer-lasting equipment.

If you’re upgrading or building a hydraulic system, make sure to invest in high-quality right-angle fittings for maximum efficiency and durability.

Post time: Aug-22-2025