Modern irrigation systems are designed to save time, water, and labor, and one small but essential component that helps achieve this is the hydraulic quick coupling valve. If you’re new to irrigation equipment or looking to upgrade your system, understanding how this valve works can make a big difference in efficiency and ease of use.

This beginner’s guide explains what a hydraulic quick coupling valve is, how it works, where it’s used, and how to choose the right one for your irrigation needs.

What Is a Hydraulic Quick Coupling Valve?

A hydraulic quick coupling valve is a type of irrigation fitting that allows hoses, pipes, or sprinklers to be connected and disconnected quickly without shutting down the entire water system. It is installed underground or above ground and remains closed when not in use, preventing water flow.

When a matching key, coupler, or valve plug is inserted, the valve opens automatically, allowing water to flow. Once the key is removed, the valve closes again, stopping the flow instantly.

In simple terms, it’s a convenient access point for water in an irrigation system.

How Does a Hydraulic Quick Coupling Valve Work?

The valve operates using a simple mechanical principle:

1. When the valve is not connected, an internal spring and seal keep it closed.

2. When a coupling key or valve plug is inserted, it pushes the internal mechanism down.

3. This opens the valve and allows water to flow through the system.

4. Removing the key causes the valve to close automatically, stopping the water.

This design makes quick-coupling valves ideal for systems where frequent connection and disconnection are required.

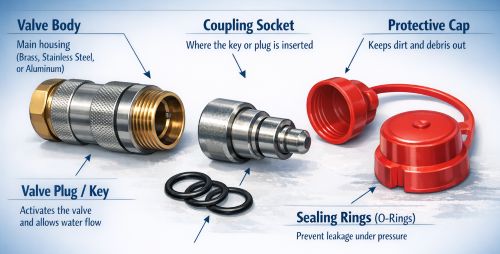

Key Components of a Hydraulic Quick Coupling Valve

Understanding the main parts helps beginners see how the valve functions:

➡️ Valve Body – The main housing, usually made of brass, stainless steel, or aluminum

➡️ Coupling Socket – The opening where the key or plug is inserted

➡️ Valve Plug / Key – Activates the valve and allows water flow

➡️ Sealing Rings (O-rings) – Prevent leakage under pressure

➡️ Protective Cap – Keeps dirt and debris out when the valve is not in use

Each component plays a role in maintaining water control and preventing system damage.

Types of Hydraulic Quick Coupling Valves

There are several types available, depending on application and system design:

1. Straight-Type Valves – Common for underground irrigation systems

2. Angled Valves – Used where space or pipe layout requires a bend

3. Single Shut-Off Valves – Shut off flow on one side

4. Double Shut-Off Valves – Shut off flow on both sides for added safety

5. Manual vs Automatic Valves – Automatic valves close instantly when disconnected

Choosing the right type depends on how and where the valve will be used.

Common Materials Used

Hydraulic quick coupling valves are manufactured from different materials, each with its own advantages:

1. Brass – Durable, corrosion-resistant, and widely used

2. Stainless Steel – Excellent for high-pressure or corrosive environments

3. Aluminum – Lightweight and cost-effective

4. Plastic or Composite – Suitable for low-pressure or residential systems

Material selection affects durability, pressure tolerance, and cost.

Applications in Irrigation Systems

Hydraulic quick coupling valves are widely used across many irrigation setups, including:

1. Agricultural irrigation for fields and crops

2. Landscape and garden irrigation in parks and residential areas

3. Greenhouses and nurseries

4. Portable or temporary irrigation systems

They allow users to move sprinklers or hoses easily without redesigning the system.

Benefits of Using Hydraulic Quick Coupling Valves

Using quick coupling valves offers several important advantages:

➡️ Fast and easy connection and disconnection

➡️ Reduced water loss and leakage

➡️ Improved flexibility in irrigation layout

➡️ Significant time and labor savings

➡️ Better water control and system safety

These benefits make them especially useful for beginners and professionals alike.

How to Choose the Right Hydraulic Quick Coupling Valve

When selecting a valve, consider the following factors:

1. Pipe size and connection type

2. Operating pressure and flow rate

3. Compatibility with existing irrigation components

4. Environmental conditions, such as soil type and water quality

Choosing the correct valve ensures long-term performance and fewer maintenance issues.

Installation Basics for Beginners

Installing a hydraulic quick coupling valve is straightforward, but it should be done carefully:

1. Gather basic tools such as wrenches and sealing tape

2. Ensure the valve is installed at the correct depth

3. Align the valve properly to avoid stress on pipes

4. Always test for leaks after installation

5. Avoid over-tightening and ensure seals are correctly placed.

Maintenance and Care Tips

Regular maintenance keeps the valve working efficiently:

1. Inspect valves periodically for leaks or damage

2. Clean dirt and debris from the coupling socket

3. Replace worn O-rings as needed

4. Use protective caps when valves are not in use

5. Proper care can significantly extend the valve’s lifespan.

Common Problems and Troubleshooting

Some common issues include:

➡️ Leakage – Often caused by worn seals

➡️ Difficulty connecting – Usually due to debris or misalignment

➡️ Valve not closing properly – May indicate internal wear

If problems persist, replacement is often more cost-effective than repair.

Frequently Asked Questions

1. Are hydraulic quick coupling valves interchangeable?

Not always. Compatibility depends on size, pressure rating, and manufacturer standards.

2. Can they handle high-pressure irrigation systems?

Yes, if the valve is designed and rated for high-pressure use.

3. How long do they last?

With proper maintenance, they can last many years.

4. Are they suitable for portable irrigation systems?

Absolutely. They are ideal for portable and flexible setups.

Conclusion

Hydraulic quick coupling valves are a simple yet powerful solution for improving irrigation efficiency. For beginners, they offer an easy way to connect and disconnect equipment, reduce water waste, and gain better control over irrigation systems.

By understanding how they work and choosing the right valve for your needs, you can build a more reliable, flexible, and efficient irrigation system.

Post time: Feb-05-2026