Pipe unions are small but critical components in piping systems. While they are often viewed as simple connectors, misunderstanding how they interact with flow direction can lead to leaks, inefficiencies, safety risks, and costly rework.

Correctly understanding and implementing flow direction in pipe unions is essential for maintaining system performance, ensuring safety, and meeting industry standards. This topic is especially important for engineers, plumbers, piping designers, maintenance teams, and contractors who design, install, or service fluid systems.

This article provides a comprehensive guide to pipe union flow direction, covering fundamentals, applicable standards, design considerations, installation best practices, common mistakes, maintenance guidance, real-world examples, and frequently asked questions.

Understanding Pipe Unions

What Is a Pipe Union?

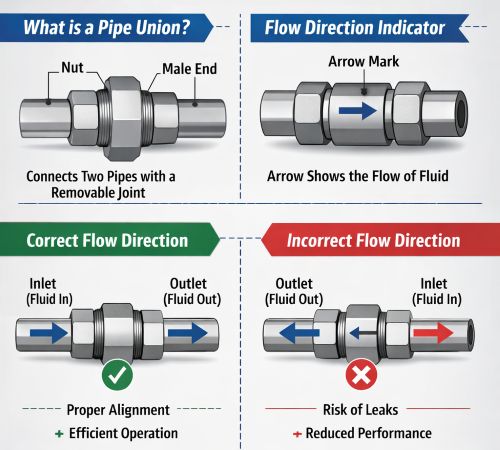

A pipe union is a type of fitting designed to join two pipes in a way that allows easy disconnection and reconnection without cutting the pipe or disturbing adjacent components. It typically consists of three parts:

1. Two threaded or welded ends

2. A central nut that draws the ends together

3. A sealing surface or gasket that prevents leaks

Pipe unions are commonly used where frequent maintenance, inspection, or equipment replacement is required.

How Pipe Unions Differ from Other Pipe Fittings

1. Couplings: Permanent or semi-permanent connections that usually require pipe rotation for removal.

2. Flanges: Bolted connections that take more space and require additional hardware.

3. Pipe unions: Compact, easy to disconnect, and ideal for tight spaces or maintenance-heavy systems.

Common Types of Pipe Unions

1. Threaded Unions

➡️ Most common in residential and light industrial systems

➡️ Easy to install and remove

➡️ Suitable for low to moderate pressure applications

2. Grooved Unions

➡️ Used in fire protection and industrial piping

➡️ Allow quick assembly with mechanical couplings

➡️ Accommodate some movement and vibration

3. Welded Unions

➡️ Used in high-pressure or high-temperature systems

➡️ Provide strong, leak-resistant connections

➡️ Less flexible for frequent disassembly

4. Quick-Release Unions / Wing Nut Unions

➡️ Designed for rapid connection and disconnection

➡️ Common in temporary or mobile systems

➡️ Often used in process and utility applications

What Is Flow Direction?

Flow direction refers to the intended path that a fluid—liquid or gas—travels through a piping system. It is usually determined during system design and is critical for ensuring proper operation of valves, meters, pumps, and some fittings.

Why Flow Direction Matters

Correct flow direction:

1. Maintains sealing integrity

2. Prevents erosion or turbulence

3. Protects sensitive components

4. Ensures safety and regulatory compliance

Flow Direction vs. Orientation

Flow direction is about how the fluid moves, while orientation refers to how the component is physically positioned (horizontal, vertical, angled).

Example:

A pipe union may be installed horizontally or vertically (orientation), but if it contains a sealing design that favors a specific flow path, installing it backwards can cause leaks or pressure loss, even if it “looks” correct.

Standards and Guidelines

Relevant Industry Standards

Several standards govern piping components and indirectly influence pipe union flow direction:

1. ANSI / ASME: Pressure ratings, dimensional requirements, and performance

2. ISO: International design and testing standards

3. ASTM: Material specifications

4. API: Guidelines for oil and gas piping systems (where applicable)

Specific Standards for Flow Direction

While pipe unions are often bidirectional, standards address:

1. Flow arrows on fittings when direction matters

2. Marking requirements for pressure, size, and materials

3. Compatibility with directional components like valves and meters

Regional Variations

1. North America: ASME, ANSI, ASTM dominate

2. Europe: ISO and EN standards

3. Asia: Combination of ISO and local standards

Compliance with regional standards is critical for safety, inspections, and liability protection.

Flow Direction in Pipe Union Design

How Pipe Unions Are Marked

Some pipe unions include:

➡️ Flow arrows

➡️ Cast or stamped markings

➡️ Manufacturer labels

➡️ Not all unions require flow markings, but when present, they must be followed.

Internal Design Considerations

➡️ Sealing surfaces may be tapered or asymmetrical

➡️ Gaskets may seat differently depending on flow

➡️ Internal contours can influence turbulence and wear

Does a Pipe Union Favor a Flow Direction?

Many standard unions are technically bidirectional, but design details, sealing methods, or system conditions may make one direction preferable.

Misconceptions to Avoid

1. “All pipe unions are flow-independent” — not always true

2. “Orientation doesn’t matter” — it can, especially in high-pressure or critical systems

Best Practices for Installation

1. Planning Before Installation

➡️ Read manufacturer specifications

➡️ Check for flow arrows or markings

➡️ Review system schematics and flow diagrams

2. Correct Installation Methods

➡️ Align union halves carefully to avoid cross-threading

➡️ Ensure correct flow direction where specified

➡️ Tighten to recommended torque—avoid overtightening

3. Field Tips for Troubleshooting

➡️ Look for unusual leaks or vibration

➡️ Compare installation against drawings

➡️ If flow direction is unclear, consult manufacturer documentation

Common Mistakes and How to Avoid Them

1. Ignoring flow direction labels: Always inspect markings

2. Installing unions backwards: Double-check before final tightening

3. Using the wrong union type: Match pressure, temperature, and media

4. Failing to verify standards compliance: Ensure codes and regulations are met

Maintenance and Inspection

1. Routine Inspection Tips

➡️ Check for leaks around sealing surfaces

➡️ Inspect alignment and nut tightness

➡️ Ensure flow indicators remain visible and legible

2. When to Replace a Pipe Union

Signs of failure include:

➡️ Persistent leaks

➡️ Corrosion or cracking

➡️ Damaged threads or sealing faces

Preventive replacement is often more cost-effective than reactive repairs after a failure.

Case Studies

Example #1: Industrial Water System

Problem: Frequent leaks at pipe unions

Cause: Incorrect flow direction relative to sealing design

Solution: Reinstallation following manufacturer flow guidelines

Outcome: Reduced leaks and improved system reliability

Example #2: HVAC Piping

Issue: Noise and pressure loss

Lesson Learned: Flow direction and orientation both matter

Best Practice: Clear labeling and installer training prevented recurrence

Frequently Asked Questions (FAQ)

Do all pipe unions have a preferred flow direction?

No. Many are bidirectional, but some designs or applications require correct flow alignment.

Can a pipe union be installed in any orientation?

Orientation may vary, but flow direction requirements must still be followed if specified.

What if flow direction isn’t marked?

Check manufacturer documentation or consult technical support before installation.

Conclusion

Understanding pipe union flow direction is essential for building safe, efficient, and compliant piping systems. While pipe unions may seem simple, ignoring design details, standards, or markings can lead to serious operational issues.

By following industry standards, respecting flow direction guidelines, and applying best installation and maintenance practices, engineers and technicians can significantly improve system reliability and longevity.

Always treat pipe unions as engineered components, not just connectors, and verify flow direction requirements before installation.

Post time: Jan-09-2026