When working with piping, fluid systems, or mechanical assemblies, choosing the right type of thread can be the difference between a secure, leak-free system—and a costly, dangerous failure. One of the most common points of confusion arises when distinguishing between NPT (National Pipe Taper) threads and RC (BSPT/PT) threads.

At a glance, these threads may look nearly identical, but mixing them can lead to serious issues like leaks, stripped threads, or even system failure under pressure. This post breaks down the key differences between these two thread types and why it’s essential to use the correct one.

What Are NPT and RC Threads?

What is NPT? (National Pipe Taper)

NPT, short for National Pipe Taper, is a standard used predominantly in North America. Defined by ANSI/ASME B1.20.1, NPT threads are tapered, meaning the diameter decreases slightly along the thread length to create a pressure-tight seal.

➡️ Seal mechanism: Relies on thread deformation and sealant (e.g., Teflon tape or pipe dope)

➡️ Common uses: Plumbing, industrial piping, hydraulic systems in North America

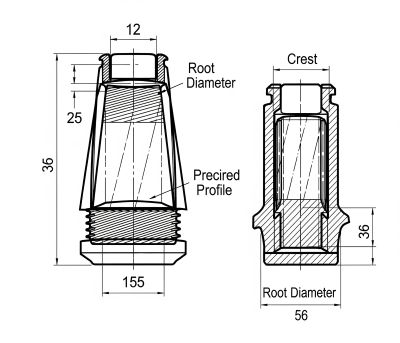

➡️ Design: Tapered threads with a 60° thread angle and flattened crests and roots

What is RC Thread? (Also known as BSPT or PT)

RC thread, also known as BSPT (British Standard Pipe Taper) or PT (as per JIS standards in Japan), is used internationally, particularly in Europe and Asia. It’s defined by ISO 7-1 and JIS B0203 standards.

➡️ Seal mechanism: Similar to NPT—relies on taper and thread deformation

➡️ Common uses: Pneumatic and hydraulic equipment, international machinery

➡️ Design: 55° thread angle with a rounded crest and root

Key Differences Between NPT and RC Threads

|

Feature |

NPT |

RC (BSPT) |

|

Standard |

ANSI/ASME B1.20.1 |

ISO 7-1 / JIS B0203 |

|

Thread Angle |

60° |

55° |

|

Thread Profile |

Flattened crest and root |

Rounded crest and root |

|

Taper Rate |

1 in 16 |

1 in 16 |

|

Compatibility |

Not interchangeable |

Not interchangeable |

|

Common Use Region |

North America |

Europe, Asia, international |

Despite similarities in taper rate and function, the different thread angles and profiles make NPT and RC threads incompatible. Trying to force one into the other often results in poor sealing and damage.

How to Identify NPT vs RC Threads

Identifying the right thread type before assembly is critical. Here are a few methods:

Visual Inspection: RC threads tend to have a slightly more rounded appearance, while NPT threads look sharper.

Thread Gauge & Caliper: Use a thread pitch gauge and calipers to measure thread count per inch and major/minor diameters.

Check Thread Angle: Use an optical comparator or thread angle gauge to differentiate 60° (NPT) from 55° (RC).

Look for Markings: Fittings often come stamped with “NPT,” “BSPT,” or “PT.” Always confirm before use.

Why It Matters – Practical Implications

Using the wrong thread type can lead to a host of problems:

Leaks: Mismatched threads won’t seal correctly, even with thread sealant.

Thread Damage: Forcing incompatible threads together may strip or gall the material.

Safety Risks: In pressurized systems, leaks or failures can cause injury or equipment damage.

Repair Costs: Fixing damaged threads often means replacing expensive components or fittings.

For both professionals and DIYers, these risks highlight the importance of matching thread types exactly.

Can NPT and RC Threads Be Used Together?

Short Answer: No, they shouldn’t be.

While some users try to force a seal using Teflon tape or pipe dope, this approach is not reliable or safe, especially under pressure. Most manufacturers specifically warn against mixing thread types.

When and How to Connect Them Safely:

➡️ Use certified adapters or converters designed to transition from NPT to BSPT/RC threads

➡️ Always follow the pressure ratings and material compatibility of the adapter

➡️ Confirm thread standards using the product’s technical documentation

Best Practices When Working With Threaded Connections

To avoid issues, follow these simple guidelines:

Verify Thread Type: Don’t guess. Always confirm the standard before assembly.

Use Proper Tools: A thread pitch gauge and calipers are essential for identification.

Sealants: Use them only when specified—and never rely on them to “fix” mismatched threads.

Avoid Mixing Threads: Unless you’re using a certified adapter, mixing threads is a gamble.

Consult Documentation: Manufacturer specs and equipment manuals often list compatible thread types.

Conclusion

NPT and RC threads may look similar, but they are fundamentally different in angle, profile, and compatibility. Knowing the difference isn’t just about being technically correct—it’s about ensuring your systems are safe, reliable, and leak-free.

Before you tighten the next fitting, double-check the thread type. If you’re unsure, consult a tech chart or reach out to the manufacturer. When in doubt, don’t force it—adapt it.

Post time: May-22-2025