Choosing the right type of fitting isn’t just a technical detail. It directly impacts safety, leak prevention, durability, and overall system performance. With so many connection standards used across industries, selecting the wrong fitting can lead to costly failures or maintenance issues later on.

Both NPT (National Pipe Tapered) and Inverted Flare fittings are widely used in HVAC, automotive fuel and brake lines, hydraulic systems, gas lines, and plumbing. But they work differently, and mixing them up can cause serious connection problems.

This guide simplifies the comparison to help you quickly determine which type of fitting is right for your application.

What Are NPT Fittings?

NPT (National Pipe Tapered) fittings are a threaded connection standard widely used across the U.S.

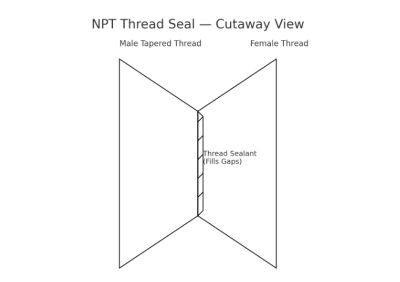

How NPT Works

NPT threads are cut at a slight taper. As you tighten them together, the threads compress and deform, creating a seal. However, the threads alone are rarely enough for a leak-proof connection — they need thread sealants such as:

➡️ PTFE tape (Teflon tape)

➡️ Pipe dope

Advantages of NPT

1. Highly standardized and easy to source

2. Low-cost and simple to install

3. Works with many different materials (steel, brass, PVC, aluminum, etc.)

Limitations of NPT

1. Thread sealant required to avoid leaks

2. Threads may gall or wear with repeated tightening

3. Over-tightening can crack fittings or deform threads

Common NPT Applications

1. Residential and industrial plumbing

2. Gas lines (when using proper sealant)

3. Low- to medium-pressure fluid systems

What Are Inverted Flare Fittings?

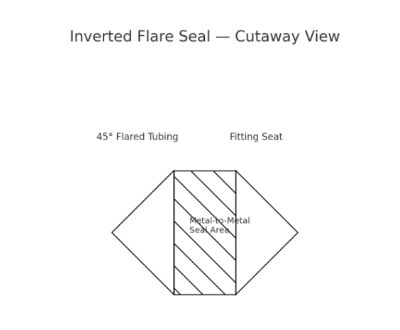

Inverted flare fittings are a style of flare fittings using a 45° inward (inverted) flare. These fittings create a metal-to-metal mechanical seal rather than relying on the threads.

How Inverted Flare Works

The tubing end is flared outward at 45° and seats into a conical cavity inside the fitting. When tightened:

1. The flare compresses into the matching seat

2. A strong, leak-proof seal forms without sealant

Advantages of Inverted Flare

1. Reliable seal — even under high pressure

2. Resistant to vibration

3. No thread sealants required

4. Connections are reusable and long-lasting

Limitations of Inverted Flare

1. Must be flared correctly (precision required)

2. Higher cost than NPT fittings

3. Compatible only with certain metal tubing materials

Common Inverted Flare Applications

1. Automotive brake and fuel systems

2. Hydraulic and pneumatic systems

3. HVAC and refrigeration lines

4. High-vibration machinery

NPT vs. Inverted Flare: Head-to-Head Comparison

|

Feature |

NPT |

Inverted Flare |

|

Sealing Method |

Thread deformation + sealant |

Metal-to-metal compression |

|

Leak Prevention |

Depends heavily on sealant and installation |

Consistent if flared properly |

|

Pressure Rating |

Variable, generally lower |

Higher, ideal for hydraulic use |

|

Vibration Resistance |

Weaker — prone to loosening |

Excellent resistance |

|

Reusability |

Threads degrade over time |

Highly reusable |

|

Tools/Installation |

Simple tools |

Requires flaring tools & technique |

|

Cost |

Lower upfront |

Slightly higher |

|

Material Compatibility |

Works with many piping materials |

Mainly metal tubing |

|

Best For |

General-purpose plumbing |

Precision and high-pressure lines |

When to Use NPT Fittings

Choose NPT when you need:

✔ Quick and simple installation

✔ Cost-effective connections

✔ Low- to medium-pressure piping

✔ Wide material compatibility

✔ Systems with minimal vibration

Examples: residential plumbing, general gas lines, irrigation systems

When to Use Inverted Flare Fittings

Choose an inverted flare when you need:

✔ High-pressure sealing

✔ Vibration resistance

✔ Leak-proof results without sealants

✔ Reusable connections

Examples: brake lines, high-vibration hydraulics, refrigeration systems

Common Mistakes to Avoid

|

Mistake |

Why It’s a Problem |

|

Over-tightening NPT threads |

Can crack fittings or strip threads |

|

Using sealant on inverted flare threads |

Prevents proper metal-to-metal contact |

|

Incorrect flaring angle |

Causes leaks and weak connections |

|

Mixing standards (NPT vs flare) |

They are not interchangeable |

Choosing the Right Fitting: Quick Decision Guide

1. Need metal-to-metal sealing? → Inverted Flare

2. Need a fast, cheap, general-purpose connection? → NPT

3. High vibration environment? → Inverted Flare

4. Working with PVC or soft metals? → NPT

5. High-pressure hydraulic system? → Inverted Flare

Conclusion

Both NPT and inverted flare fittings serve important roles, but they’re designed for very different environments:

➡️ NPT: Best for cost-efficient plumbing tasks and moderate-pressure systems where sealant use is acceptable.

➡️ Inverted Flare: Ideal for critical, high-pressure, or high-vibration applications requiring long-term reliability.

Before choosing a fitting, always consider:

✔ Operating pressure

✔ Vibration levels

✔ Tubing material

✔ Need for reusability

✔ Installation skill and tools

Choosing the right fitting from the start means safer, more durable, and more efficient fluid system performance.

Post time: Dec-05-2025