When it comes to mechanical design, assembly, and manufacturing, screw threads are one of the most critical yet overlooked components. They’re the backbone of fasteners, ensuring that parts are held together securely and precisely.

Standardization, especially through ISO metric threads, plays a crucial role in maintaining compatibility, performance, and interchangeability across industries. Without it, bolts, nuts, and components from different manufacturers would rarely fit together correctly.

In this guide, we’ll explore everything you need to know about standard metric screw threads, from their anatomy and naming system to size charts, tolerances, and applications.

What Are Metric Screw Threads?

A metric screw thread is a type of thread where all dimensions are expressed in millimeters. It’s defined by the ISO (International Organization for Standardization), making it the global standard for fasteners used in engineering and manufacturing.

These threads form a helical ridge around a cylindrical shaft, allowing screws and bolts to convert rotational motion into linear motion, essentially creating a firm mechanical grip.

Metric vs. Imperial Threads

Metric threads use millimeters for measurement, while imperial (inch-based) threads, such as UNC/UNF, are measured in inches and threads per inch (TPI).

For example:

➡️ M10 × 1.5 → Metric thread (10 mm diameter, 1.5 mm pitch)

➡️ 3/8-16 UNC → Imperial thread (3/8 inch diameter, 16 threads per inch)

Common ISO Standards

Several ISO standards define metric screw threads:

➡️ ISO 68-1 – Basic profile for ISO metric threads

➡️ ISO 261 – General-purpose metric screw thread standards

➡️ ISO 965 – Tolerances, limits of sizes, and thread fit classes

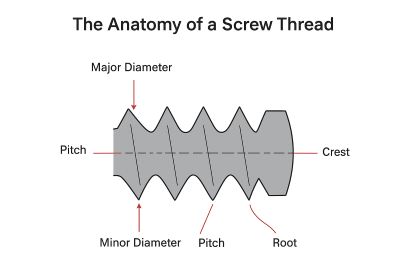

The Anatomy of a Screw Thread

Understanding thread geometry is essential for proper measurement and design.

Here are the key components:

➡️ Major Diameter: The outermost diameter of the thread.

➡️ Minor Diameter: The innermost diameter at the root of the thread.

➡️ Pitch Diameter: The imaginary diameter halfway between the major and minor diameters — crucial for thread engagement.

➡️ Pitch: The distance between two adjacent thread peaks, measured parallel to the axis.

➡️ Flank Angle: The angle formed between the sides of adjacent threads (for metric threads, typically 60°).

➡️ Crest and Root: The top (crest) and bottom (root) of the thread ridge.

Metric Screw Thread Designation Explained

Metric screw threads follow a standardized naming format:

Example: M10 × 1.5

Here’s what it means:

➡️ M = Metric thread

➡️ 10 = Nominal diameter in millimeters

➡️ 1.5 = Pitch (distance between threads in mm)

If no pitch is specified, it usually refers to the coarse pitch. For example, “M10” generally means “M10 × 1.5.”

Common examples:

➡️ M6 × 1.0 – Medium machine screws

➡️ M8 × 1.25 – Automotive and machinery bolts

➡️ M12 × 1.75 – Heavy-duty applications

ISO Metric Thread Series (Coarse, Fine, and Extra Fine)

Metric threads come in three main series, depending on their pitch:

|

Thread Type |

Description |

Typical Use |

|

Coarse (M) |

Standard pitch, easiest to assemble |

General-purpose fastening |

|

Fine (MF) |

Smaller pitch, stronger hold |

Automotive, precision machinery |

|

Extra Fine (MEF) |

Very small pitch |

Aerospace and specialized components |

Advantages Comparison:

|

Feature |

Coarse Threads |

Fine Threads |

|

Ease of Assembly |

Easier to start and tighten |

Requires precision |

|

Strength |

Moderate |

Higher tensile strength |

|

Resistance to Loosening |

Lower |

Higher (due to more threads per length) |

|

Common Use |

General |

Precision and vibration-prone areas |

Metric Screw Thread Size Chart (M1–M100)

Below is a simplified reference chart for standard metric threads:

|

Thread Size |

Pitch (mm) |

Major Dia (mm) |

Minor Dia (mm) |

Tap Drill Size (mm) |

|

M3 |

0.5 |

3.00 |

2.39 |

2.5 |

|

M4 |

0.7 |

4.00 |

3.30 |

3.3 |

|

M5 |

0.8 |

5.00 |

4.13 |

4.2 |

|

M6 |

1.0 |

6.00 |

4.92 |

5.0 |

|

M8 |

1.25 |

8.00 |

6.75 |

6.8 |

|

M10 |

1.5 |

10.00 |

8.35 |

8.5 |

|

M12 |

1.75 |

12.00 |

9.85 |

10.2 |

|

M16 |

2.0 |

16.00 |

13.55 |

14.0 |

|

M20 |

2.5 |

20.00 |

16.93 |

17.5 |

Most frequently used sizes: M3, M6, M8, M10, M12.

Tolerances and Fit Classes

Thread tolerances ensure proper fit, function, and interchangeability between mating parts.

➡️ External Threads (Bolts): Usually designated as 6g

➡️ Internal Threads (Nuts): Usually designated as 6H

A combination of these (e.g., 6H/6g) ensures a medium fit, balancing strength and ease of assembly.

Tip: Tight tolerances (e.g., 4H/4g) are used for precision applications, while looser ones (e.g., 7H/7g) are for general-purpose threads.

Tools and Gauges for Measuring Metric Threads

Accurate measurement ensures proper fit and avoids cross-threading. Common tools include:

➡️ Thread Gauges – For checking pitch and fit

➡️ Pitch Gauges – To identify thread spacing

➡️ Micrometers & Calipers – For measuring major/minor diameters

➡️ Optical Comparators – For high-precision inspection

How to identify an unknown metric thread:

1. Measure the outer diameter using a caliper.

2. Use a pitch gauge to determine thread spacing.

3. Compare your measurements to a metric thread chart.

Applications of Metric Screw Threads

Metric threads are widely used across industries such as:

1. Automotive – Engine parts, brackets, and chassis bolts

2. Construction – Steel framing and anchor bolts

3. Machinery – Fastening machine components

4. Electronics – Compact assemblies and housings

Their global standardization ensures components made in different countries fit perfectly — a must for international manufacturing.

Common Issues and Troubleshooting Tips

Common problems:

➡️ Cross-threading

➡️ Incorrect pitch selection

➡️ Damaged threads or poor fit

Prevention tips:

➡️ Use proper torque settings.

➡️ Apply thread lubricants or anti-seize compounds.

➡️ Inspect threads regularly with gauges or magnifiers.

Metric vs. Imperial Thread Comparison

|

Feature |

Metric (ISO) |

Imperial (UNC/UNF) |

|

Measurement Unit |

Millimeters |

Inches |

|

Pitch |

Distance between threads (mm) |

Threads per inch (TPI) |

|

Common Designation |

M10 × 1.5 |

3/8-16 UNC |

|

Global Use |

Worldwide |

Mostly US and UK |

|

Standard |

ISO 68-1, ISO 261 |

ASME B1.1 |

Why the shift to metric?

Global manufacturing now prioritizes ISO metric standards because they simplify design, reduce conversion errors, and ensure international compatibility.

FAQs

1. What is the most common metric thread size?

M6 and M8 are the most commonly used sizes in mechanical and industrial applications.

2. What does M10 × 1.5 mean?

It means a metric thread with a 10 mm nominal diameter and 1.5 mm pitch (distance between threads).

3. Can I use metric bolts in imperial threads?

No. Mixing metric and imperial threads can cause cross-threading and mechanical failure. Always use matching thread standards.

Conclusion

Understanding standard metric screw threads is essential for ensuring mechanical compatibility, precision, and safety. With ISO-defined sizes and tolerances, engineers and manufacturers can design systems that are universally reliable.

Refer to this guide and chart whenever you’re working with fasteners, and if you need deeper insight, consider downloading a printable metric thread chart for quick reference in your workspace.

Post time: Oct-29-2025