Hydraulic systems play a critical role in modern machinery, powering everything from construction equipment and industrial automation to agricultural and marine applications. These systems rely on pressurized fluid to transmit force and motion efficiently. However, one major challenge arises when hydraulic fluid must be transferred between stationary and rotating components.

This is where hydraulic swivel joints come into play. Designed to allow the continuous flow of hydraulic fluid while parts rotate, swivel joints are essential for smooth, safe, and efficient machine operation.

In this article, you’ll learn what a hydraulic swivel joint is, how it works, why it’s important, and how to choose and maintain the right one for your application.

What Is a Hydraulic Swivel Joint?

A hydraulic swivel joint is a mechanical component that allows hydraulic fluid to flow between a stationary part and a rotating part of a machine without twisting or damaging hoses. It enables rotation, often up to 360 degrees or more, while maintaining a sealed fluid connection under pressure.

Hydraulic swivel joints are also commonly known as hydraulic rotary joints, swivel couplings, or rotary swivel joints, depending on the industry and application.

The core purpose of a hydraulic swivel joint is simple but vital: to transfer hydraulic fluid during rotation. Unlike fixed hydraulic connections, which are rigid and cannot rotate, swivel joints are specifically engineered to handle continuous or intermittent rotational movement without leakage or pressure loss.

Why Hydraulic Swivel Joints Are Important

Hydraulic swivel joints are crucial to the performance and longevity of hydraulic systems for several reasons.

First, they prevent hose twisting and damage. Without a swivel joint, rotating motion would twist hydraulic hoses, leading to kinks, premature wear, and eventual failure.

Second, swivel joints enable continuous rotation and movement, which is essential for machinery such as excavators, cranes, and rotating platforms that require unrestricted motion.

They also improve machine efficiency and safety by maintaining consistent fluid flow and pressure, reducing the risk of sudden hose bursts or fluid leaks that could endanger operators.

Finally, hydraulic swivel joints reduce downtime and maintenance costs. By protecting hoses and connections from stress and wear, they extend the service life of hydraulic components and minimize unplanned repairs.

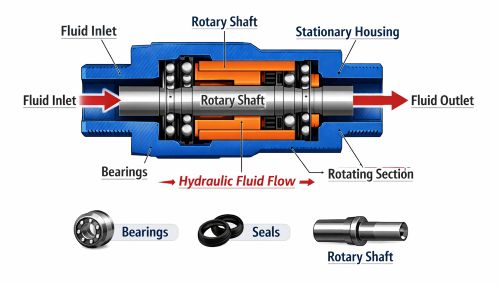

Main Components of a Hydraulic Swivel Joint

A hydraulic swivel joint consists of several key components, each playing a critical role in its performance:

➡️ Housing and Body: The outer structure that contains and protects the internal components while providing mounting points.

➡️ Rotating Shaft or Spindle: The internal part that rotates relative to the housing and allows fluid transfer between the stationary and moving sections.

➡️ Bearings: Ball, roller, or plain bearings support smooth rotation and reduce friction and wear.

➡️ Sealing System: O-rings, lip seals, or mechanical seals prevent hydraulic fluid from leaking, even under high pressure.

➡️ Ports and Flow Passages: Internal channels and external ports guide the hydraulic fluid through the joint to the connected hoses or pipes.

How Does a Hydraulic Swivel Joint Work?

The working principle of a hydraulic swivel joint is straightforward but highly engineered.

Hydraulic fluid enters the swivel joint through a stationary inlet port. Inside the joint, the fluid flows through precisely machined internal passages within the rotating shaft or body. As the connected component rotates, bearings ensure smooth movement, allowing rotation without resistance or misalignment.

At the same time, seals maintain a tight barrier, preventing fluid from escaping even under high pressure. These seals are designed to accommodate rotation while maintaining consistent contact between moving and stationary parts.

Hydraulic swivel joints can be single-channel (single-pass), allowing one fluid line to pass through, or multi-channel (multi-pass), enabling multiple fluid lines, such as pressure, return, and pilot lines, to flow simultaneously through a single unit.

Types of Hydraulic Swivel Joints

Hydraulic swivel joints come in several types to suit different applications:

➡️ Single-pass swivel joints: Designed for systems with one hydraulic circuit.

➡️ Multi-pass swivel joints: Support multiple independent fluid channels within one joint.

➡️ Low-pressure swivel joints: Used in applications with moderate pressure requirements.

➡️ High-pressure swivel joints: Engineered to withstand demanding hydraulic pressures.

➡️ Standard swivel joints: Off-the-shelf solutions for common applications.

➡️ Custom-designed swivel joints: Tailored for specific pressure, flow, or environmental needs.

Common Applications of Hydraulic Swivel Joints

Hydraulic swivel joints are used across a wide range of industries, including:

1. Construction equipment such as excavators, cranes, loaders, and drilling rigs

2. Industrial machinery and automation systems

3. Mobile hydraulic systems, including trucks and material-handling equipment

4. Offshore, marine, and agricultural equipment, where rotation and durability are critical

Hydraulic Swivel Joint vs. Rotary Union

Hydraulic swivel joints and rotary unions share similar functions, as both allow fluid transfer during rotation. However, there are important differences.

Swivel joints are typically designed for hydraulic fluid and higher-pressure applications, while rotary unions may handle a wider range of media, such as air, steam, or coolant.

A hydraulic swivel joint is preferred when high pressure, durability, and mobile equipment are involved. A common misconception is that the two terms are interchangeable, but their design and intended use often differ significantly.

Key Benefits of Using Hydraulic Swivel Joints

Using hydraulic swivel joints offers several advantages:

1. 360-degree continuous rotation without hose twisting

2. Increased system reliability and consistent performance

3. Compact, space-saving design

4. Improved operator safety

5. Longer service life for hoses, seals, and connected components

Factors to Consider When Choosing a Hydraulic Swivel Joint

Selecting the right swivel joint requires careful evaluation of several factors:

1. Operating pressure and flow rate

2. Number of fluid channels required

3. Rotation speed and duty cycle

4. Type and temperature of hydraulic fluid

5. Environmental conditions, such as dust, moisture, corrosion, or extreme temperatures

Installation and Maintenance Basics

Proper installation is critical for swivel joint performance. Always ensure correct alignment and follow manufacturer’s torque specifications for mounting and fittings.

Routine inspections should check for leaks, unusual noise, vibration, or reduced performance. Common signs of wear include fluid seepage, increased resistance to rotation, or pressure loss.

Basic maintenance best practices include keeping the joint clean, monitoring operating conditions, and replacing seals or bearings when necessary to avoid larger system failures.

Common Problems and Troubleshooting

Some common issues with hydraulic swivel joints include:

1. Leakage, often caused by worn or damaged seals

2. Seal wear or bearing failure due to contamination or misalignment

3. Pressure loss resulting from internal wear or improper sizing

In many cases, minor issues can be repaired by replacing seals or bearings. However, severe wear or structural damage may require the complete replacement of the swivel joint.

Frequently Asked Questions (FAQ)

What is the lifespan of a hydraulic swivel joint?

Lifespan depends on operating conditions, maintenance, and quality, but many swivel joints last several years in normal use.

Can hydraulic swivel joints handle high pressure?

Yes, high-pressure swivel joints are specifically designed to operate safely under demanding hydraulic pressures.

Are swivel joints customizable?

Many manufacturers offer custom swivel joints tailored to specific pressure, flow, size, or environmental requirements.

How often should swivel joints be maintained?

Regular inspections should be part of routine maintenance, with servicing intervals based on usage and operating conditions.

Looking for more expert insights for your hydraulic system? Take a tour at these resources ⬇️ ⬇️ ⬇️

Hydraulic Thread Compatibility: G Pipe Thread vs NPT Explained

What Is a Hydraulic Compression Tee Fitting and How Does It Work?

Compression Fitting Diagrams and Dimensional Standards for Professionals

Conclusion

Hydraulic swivel joints are essential components in modern hydraulic systems, enabling safe and efficient fluid transfer during rotation. By preventing hose twisting, improving reliability, and supporting continuous movement, they play a vital role in machine performance.

Choosing the right hydraulic swivel joint, and installing and maintaining it properly, can significantly enhance efficiency, safety, and long-term operational reliability. Whether in construction, industrial, or mobile applications, a well-selected swivel joint is an investment in performance and durability.

Post time: Dec-19-2025