Modern machines rely on hydraulic systems to perform heavy work efficiently. These systems use pressurized fluid to power lifting, pushing, and rotating under extreme loads.

However, hydraulic components often come from different manufacturers and standards, making them hard to connect. Hydraulic pump adapters solve this problem by allowing different parts to fit together and work as one system.

This article explains what hydraulic pump adapters are, why they matter, and how choosing the right one improves reliability and performance.

What Are Hydraulic Pump Adapters?

Hydraulic pump adapters are precision-engineered components designed to connect a hydraulic pump to another part of the hydraulic system, such as a motor, hose assembly, or manifold, when direct compatibility does not exist.

Their primary function is to ensure a secure mechanical connection, proper alignment, and a leak-free hydraulic seal while allowing pressurized fluid to flow efficiently between components. Unlike general hydraulic fittings, which typically connect hoses or pipes, pump adapters are often responsible for handling higher loads, precise alignment, and torque transmission.

Hydraulic pump adapters are widely used across industries that depend on high-performance hydraulic systems, including construction, agriculture, manufacturing, marine operations, and mobile equipment. Wherever hydraulic components must work together despite differences in design or standards, pump adapters play a vital role.

Why Hydraulic Pump Adapters Are Necessary

Every hydraulic component would share the same mounting interface, shaft type, and connection standard. In reality, the hydraulic industry is built around multiple global standards and manufacturer-specific designs.

One common challenge is compatibility. A pump may have a mounting flange that does not match the motor or gearbox it needs to connect to. Shaft dimensions, bolt patterns, and port configurations can vary widely.

Standardization differences further complicate matters. SAE, ISO, DIN, and other standards coexist, and equipment manufacturers often design systems around specific specifications.

Hydraulic pump adapters also become essential during retrofitting and system upgrades. When replacing a worn-out pump or upgrading to a more efficient model, the new component may not match the original mounting configuration. Instead of redesigning the entire system, an adapter allows the new pump to integrate smoothly.

From a cost perspective, adapters provide a practical and economical solution. Replacing entire pumps, motors, or assemblies due to minor incompatibilities is expensive. A well-designed adapter can solve the problem at a fraction of the cost.

Main Components of a Hydraulic Pump Adapter

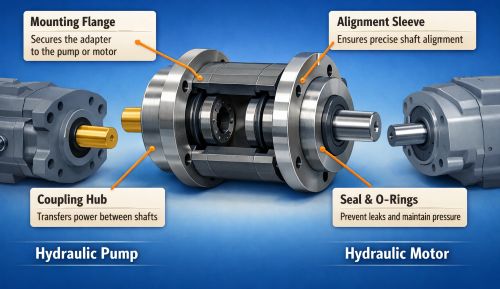

Although designs vary, most hydraulic pump adapters share several core components.

The adapter housing forms the main body and is typically machined from high-strength materials to withstand pressure, vibration, and mechanical stress. Its geometry ensures accurate alignment between connected components.

Sealing elements such as O-rings, gaskets, or face seals are critical for preventing fluid leaks. These seals must maintain integrity under high pressure and fluctuating temperatures.

Mounting flanges and bolt patterns allow the adapter to be securely fastened to the pump or mating component. Precision in these features ensures proper alignment and load distribution.

Ports and connection interfaces guide hydraulic fluid into and out of the adapter while maintaining consistent flow characteristics.

Types of Hydraulic Pump Adapters

1. Flange Adapters

Flange adapters are among the most common types used to connect pumps to motors or gearboxes.

SAE flange adapters follow standards set by the Society of Automotive Engineers and are widely used in mobile and industrial hydraulic systems. They provide reliable alignment and strong mechanical support.

ISO flange adapters conform to international standards and are commonly used in global or export-oriented equipment designs.

2. Threaded Adapters

Threaded adapters connect components using standardized threads.

Common thread types include BSP, NPT, and metric threads. These adapters are often used in lower-profile installations or where space constraints make flange connections impractical.

They are frequently found in auxiliary pump connections and compact hydraulic assemblies.

3. Shaft Adapters

Shaft adapters connect the rotating shaft of a hydraulic pump to a motor or drive system.

Splined shaft adapters are used for higher torque transmission and improved load distribution, while keyed shaft adapters are simpler and more common in moderate-duty applications.

Proper alignment is critical with shaft adapters, as misalignment can lead to vibration, noise, and premature component failure.

4. Custom Hydraulic Pump Adapters

In specialized applications, standard adapters may not meet system requirements. Custom hydraulic pump adapters are designed to match unique dimensions, loads, or environmental conditions.

Tailored designs offer precise fit, optimized performance, and extended service life, especially in demanding or non-standard applications.

How Do Hydraulic Pump Adapters Work?

Hydraulic pump adapters work by bridging physical and functional differences between components. Mechanically, they align mounting faces, shafts, and bolt patterns so that parts fit together accurately.

Hydraulically, they contain and direct pressurized fluid while minimizing turbulence and pressure loss. High-quality adapters maintain consistent flow paths and reliable sealing.

Adapters also play a role in torque transmission, especially in shaft-mounted applications. By ensuring correct alignment and secure engagement, they help prevent uneven loads and mechanical stress.

Ultimately, a properly designed adapter maintains system integrity, even under high pressure, continuous operation, and harsh working conditions.

Materials Used in Hydraulic Pump Adapters

Material selection has a direct impact on adapter performance and durability.

1. Carbon steel is commonly used due to its strength, durability, and cost-effectiveness in high-pressure environments.

2. Stainless steel offers superior corrosion resistance, making it ideal for marine, chemical, or food-processing applications.

3. Aluminum alloys are lighter and provide good corrosion resistance, often used in mobile or weight-sensitive systems.

The right material depends on operating pressure, temperature range, exposure to chemicals, and environmental conditions.

Key Performance Factors

Several performance factors determine the effectiveness of a hydraulic pump adapter.

1. Pressure ratings must meet or exceed system operating pressure to ensure safety and reliability.

2. Flow capacity affects how efficiently fluid moves through the adapter without excessive pressure drop.

3. Temperature resistance ensures seals and materials perform consistently under thermal stress.

4. Vibration and fatigue resistance are critical in mobile and high-duty-cycle applications where constant movement can weaken poorly designed components.

Common Applications of Hydraulic Pump Adapters

Hydraulic pump adapters are used across a wide range of industries.

1. Construction equipment relies on adapters to connect pumps to motors in excavators, loaders, and cranes.

2. Agricultural machinery uses adapters to integrate hydraulic systems in tractors, harvesters, and irrigation equipment.

3. Industrial manufacturing systems depend on adapters for presses, injection molding machines, and automated production lines.

4. Marine and offshore equipment requires corrosion-resistant adapters for harsh environments.

5. Mobile hydraulic systems use adapters to enable compact, flexible designs.

Installation and Maintenance Best Practices

Proper installation begins with pre-installation checks, including verifying dimensions, pressure ratings, and seal compatibility.

1. Correct torque and alignment procedures are essential to avoid stress and leaks. Over-tightening can damage seals, while under-tightening can cause loosening during operation.

2. Seals should be inspected regularly and replaced at the first signs of wear or damage.

3. Routine maintenance helps identify issues early, reducing the risk of unexpected failures and downtime.

Common Problems and How to Avoid Them

1. Leakage is often caused by improper sealing or damaged O-rings. Using the correct seal material and installation method helps prevent this issue.

2. Misalignment can lead to vibration and premature wear. Precision machining and careful installation are key to avoiding alignment problems.

3. Incorrect adapter selection, such as mismatched pressure ratings or dimensions, can compromise system performance.

4. Over-tightening or under-tightening fasteners can damage components or reduce connection stability. Following manufacturer specifications is essential.

How to Choose the Right Hydraulic Pump Adapter

Selecting the right adapter starts with matching pump and system specifications, including mounting interfaces, shaft dimensions, and pressure requirements.

1. Understanding industry standards such as SAE, ISO, and DIN helps ensure compatibility.

2. Operating conditions like pressure, temperature, and environmental exposure should guide material and design choices.

3. Working with reliable manufacturers or suppliers ensures quality, technical support, and long-term reliability.

Benefits of Using High-Quality Hydraulic Pump Adapters

High-quality adapters improve overall system reliability by ensuring proper alignment and sealing.

1. They reduce downtime by minimizing leaks, vibration, and unexpected failures.

2. Well-designed adapters extend the lifespan of pumps and connected components.

3. They also enhance safety and efficiency by maintaining consistent hydraulic performance.

Frequently Asked Questions

1. Are hydraulic pump adapters universal?

No. Adapters are designed for specific dimensions, standards, and operating conditions.

2. Can hydraulic pump adapters handle high-pressure applications?

Yes, when properly designed and rated for the system pressure.

3. When should an adapter be replaced?

Adapters should be replaced if there are signs of wear, leakage, deformation, or repeated seal failure.

4. Do adapters affect hydraulic system efficiency?

High-quality adapters have minimal impact and can actually improve efficiency by ensuring proper alignment and sealing.

Conclusion

Hydraulic pump adapters may be small components, but their impact on system performance is significant. They solve compatibility challenges, enable upgrades, and keep complex hydraulic systems running smoothly.

By understanding how hydraulic pump adapters work, selecting the right type, and installing them correctly, operators and engineers can maximize efficiency, reduce costs, and extend equipment life.

In hydraulics, the right connection makes all the difference.

Post time: Jan-20-2026