Hydraulic systems rely on precise control of fluid flow to operate efficiently and safely. Whether the goal is to regulate actuator speed, reduce pressure surges, or stabilize system performance, controlling flow is critical. One simple yet highly effective component used for this purpose is the hydraulic orifice fitting.

In this article, we’ll explain what a hydraulic orifice fitting is, how it works, where it’s used, and how to choose the right one for your hydraulic system.

What Is a Hydraulic Orifice Fitting?

A hydraulic orifice fitting is a specialized fitting designed with a fixed, precisely sized opening (orifice) that restricts hydraulic fluid flow. Unlike standard fittings that allow unrestricted flow, an orifice fitting intentionally limits flow to control speed, pressure, or system response.

These fittings are commonly used where a consistent, predictable flow restriction is required without the complexity of adjustable valves. Their simplicity makes them reliable, compact, and cost-effective for many hydraulic applications.

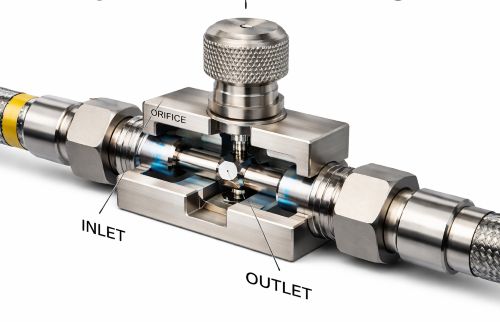

Key Components of a Hydraulic Orifice Fitting

Although hydraulic orifice fittings are simple in design, each component plays an important role:

1. Fitting Body: Typically made from carbon steel, stainless steel, or brass to withstand high pressures and harsh environments.

2. Orifice: A fixed, precision-drilled hole or insert that determines the flow rate.

3. Threaded Connections: Available in common standards such as NPT, BSPP, BSPT, JIC, or ORFS.

4. Sealing Elements: May include O-rings, metal-to-metal seals, or thread sealants to prevent leaks.

The orifice size is the most critical factor, as even a small change in diameter can significantly affect flow rate and pressure drop.

How Does a Hydraulic Orifice Fitting Work?

A hydraulic orifice fitting works by restricting the cross-sectional area through which fluid flows. When hydraulic fluid passes through the small orifice, it experiences resistance, which results in:

1. Reduced flow rate

2. Controlled actuator speed

3. A pressure drop across the fitting

The relationship between flow rate and pressure is directly influenced by the orifice diameter, fluid viscosity, and system pressure. Smaller orifices create greater resistance and higher pressure drops, while larger orifices allow more flow.

In practical terms, this means an orifice fitting can slow down a hydraulic cylinder, dampen system movement, or reduce sudden pressure spikes—all without moving parts.

Types of Hydraulic Orifice Fittings

Hydraulic orifice fittings are available in several configurations to suit different system designs:

➡️ Fixed Orifice Fittings: Feature a permanently drilled orifice for consistent flow control.

➡️ Replaceable Orifice Fittings: Allow the orifice insert to be swapped for different flow rates.

➡️ Inline Orifice Fittings: Installed directly in the hydraulic line.

➡️ Port Orifice Fittings: Installed into a valve or manifold port.

Each type offers specific advantages depending on maintenance needs, space constraints, and system flexibility.

Common Applications of Hydraulic Orifice Fittings

Hydraulic orifice fittings are widely used across industries, including:

1. Controlling cylinder and actuator speeds

2. Reducing pressure surges and shock loads

3. Damping system vibration and noise

4. Balancing flow in parallel circuits

5. Protecting sensitive hydraulic components

They are commonly found in industrial machinery, mobile equipment, agricultural systems, and material handling applications.

Advantages of Using Hydraulic Orifice Fittings

Hydraulic orifice fittings offer several key benefits:

➡️ Simple and reliable design with no moving parts

➡️ Cost-effective compared to adjustable flow control valves

➡️ Compact size, ideal for tight installations

➡️ Consistent performance once properly sized

➡️ Low maintenance requirements

These advantages make orifice fittings an excellent choice for applications requiring stable, repeatable flow control.

Limitations and Important Considerations

Despite their benefits, hydraulic orifice fittings also have limitations:

1. Flow rate is fixed and not adjustable

2. Sensitive to contamination and debris

3. Pressure drop can generate heat

4. Incorrect sizing can reduce system efficiency

5. Because of these factors, careful selection and system cleanliness are essential.

How to Choose the Right Hydraulic Orifice Fitting

Selecting the right orifice fitting involves several considerations:

1. Required flow rate and allowable pressure drop

2. Operating pressure and temperature

3. Correct orifice diameter

4. Compatible thread type and sealing method

5. Material compatibility with hydraulic fluid

Proper sizing calculations or manufacturer flow charts are often used to ensure optimal performance.

Hydraulic Orifice Fittings vs Other Flow Control Devices

Compared to flow control valves or needle valves, hydraulic orifice fittings offer:

➡️ Less flexibility but greater simplicity

➡️ Lower cost and smaller footprint

➡️ Higher reliability in fixed-flow applications

For systems that do not require adjustment, orifice fittings are often the preferred solution.

Installation and Best Practices

To ensure reliable operation:

1. Install fittings in clean hydraulic systems

2. Follow torque specifications

3. Use proper sealing methods

4. Verify flow direction if specified

5. Test system performance after installation

Good installation practices help prevent leaks, clogging, and premature failure.

Common Problems and Troubleshooting

Common issues include:

1. Reduced flow due to clogging

2. Excessive pressure drop

3. Overheating caused by restriction

4. Inconsistent system response

Regular inspection and filtration can prevent most problems.

Frequently Asked Questions

1. Can hydraulic orifice fittings be adjusted?

No, most orifice fittings have a fixed flow rate.

2. How do I determine the correct orifice size?

Orifice size is calculated based on flow rate, pressure, and fluid properties.

3. Are hydraulic orifice fittings reusable?

Yes, provided they are clean and undamaged.

4. Can they handle high pressure?

Yes, when selected within their rated pressure limits.

Conclusion

A hydraulic orifice fitting may be a small component, but it plays a critical role in controlling flow and stabilizing hydraulic systems. By understanding how it works and selecting the right design, engineers and technicians can improve system efficiency, reliability, and performance.

When used correctly, hydraulic orifice fittings provide a simple, durable, and cost-effective solution for precise flow control in a wide range of hydraulic applications.

Post time: Feb-03-2026