Hydraulic systems are the unseen power behind much of today’s heavy machinery and industrial equipment. From construction excavators and manufacturing presses to agricultural tractors and mining rigs, hydraulics make it possible to lift, move, and shape materials with immense precision and force.

However, these powerful systems rely on clean, pressurized fluid to function efficiently. When hydraulic lines are exposed to contamination, leaks, or damage, performance drops, and costly downtime or equipment failure can follow.

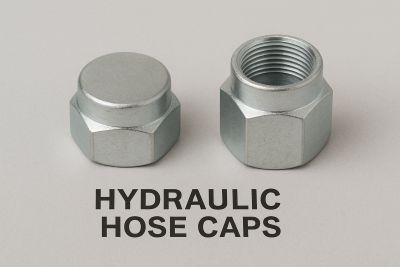

That’s where hydraulic hose caps come in. These small but vital components protect hydraulic systems from contaminants, fluid loss, and environmental hazards. In this article, we’ll explain what hydraulic hose caps are, how they work, and why they’re essential for maintaining reliable, long-lasting hydraulic equipment.

What Are Hydraulic Hose Caps?

Hydraulic hose caps are protective covers designed to seal the ends of hydraulic hoses when they are not in use. Their main function is to prevent dirt, dust, moisture, and other contaminants from entering the hydraulic system, which could otherwise compromise fluid integrity and system performance.

These caps are typically made from durable materials such as plastic, steel, brass, or aluminum, chosen based on the working environment and application.

It’s also important to distinguish between caps and plugs:

➡️ Caps cover external threads on a hose or fitting.

➡️ Plugs seal internal threads within a port or connector.

Both serve the same overall goal, to keep hydraulic systems clean, sealed, and ready for use.

Types of Hydraulic Hose Caps

Hydraulic hose caps come in several varieties, each suited to specific needs and applications:

|

Type |

Typical Use Case |

Key Advantages |

|

Threaded Hose Caps |

High-pressure systems requiring secure sealing |

Strong, vibration-resistant fit |

|

Quick-Connect Caps |

Systems needing frequent connection/disconnection |

Fast and tool-free installation |

|

Dust Caps |

Storage or transport of unused hoses |

Lightweight protection against environmental contaminants |

|

Custom / Specialized Caps |

Equipment with unique fittings or harsh conditions |

Tailored performance and material strength |

Selecting the right type ensures optimal performance and protection for your hydraulic system.

Why Hydraulic Hose Caps Are Essential

1. Protection from Contamination

Hydraulic systems are highly sensitive to contamination. Even microscopic particles of dust or metal shavings can cause wear, corrosion, and blockages that lead to reduced efficiency or complete failure.

Hose caps provide a barrier against these pollutants, ensuring your hydraulic fluid remains clean and your system performs at its best.

2. Preventing Leaks and Fluid Loss

When hoses are disconnected, fluid leakage can occur — not only wasting expensive hydraulic oil but also reducing system pressure. Hose caps seal unused hose ends, preventing drips and preserving hydraulic integrity.

3. Extending Equipment Lifespan

Clean, well-maintained hydraulic systems operate more smoothly and require fewer repairs and replacements. By preventing contamination and fluid loss, hose caps help extend the life of both hoses and connected components.

4. Safety and Environmental Benefits

Uncontrolled fluid leaks can pose slip hazards, environmental risks, and even safety threats from high-pressure spray. Properly capped hoses help prevent these incidents, promoting a safer, cleaner workspace and reducing environmental impact.

When and Where to Use Hydraulic Hose Caps

Hydraulic hose caps should be used whenever hoses are disconnected, stored, or exposed to potential contamination. Common scenarios include:

1. During maintenance or repair work – Prevent contamination while components are being serviced.

2. During transport or storage – Protect hoses and fittings in transit or when equipment is idle.

3. In harsh environments – Ideal for dusty, muddy, marine, or outdoor job sites.

4. On spare or replacement hoses – Keep backup hoses clean and ready for immediate use.

How to Select the Right Hydraulic Hose Cap

Choosing the correct cap involves considering several key factors:

1. Hose Size and Fitting Type – Match the cap to your specific hose diameter and thread type.

2. Material Selection –

➡️ Plastic: Ideal for storage and low-pressure use.

➡️ Steel or Brass: Best for heavy-duty or high-pressure environments.

3. Temperature and Pressure Ratings – Ensure the cap can withstand your operating conditions.

4. Manufacturer Compatibility – Always verify fit and performance with OEM or industry standards.

Best Practices for Using Hydraulic Hose Caps

To get the most out of your hose caps and maintain system health:

1. Clean hose ends before capping to avoid trapping contaminants inside.

2. Inspect and replace damaged caps regularly.

3. Store caps in a clean, dry location to prevent contamination.

4. Check capped hoses in storage periodically to ensure integrity and readiness.

Conclusion

Though small in size, hydraulic hose caps play a major role in maintaining hydraulic system performance, safety, and longevity. By preventing contamination, leaks, and damage, they help ensure your equipment runs efficiently and reliably, reducing costly downtime and repairs.

Protect your hydraulic system today with high-quality hose caps from Sannke.

You may also browse our full range of:

For bulk orders or technical assistance, contact our team, we’re here to help you keep your hydraulics clean, safe, and efficient.

Post time: Nov-07-2025