Hydraulic systems play a crucial role in powering machinery across a wide range of industries, from construction to aerospace. These systems rely on a network of components like pumps, cylinders, hoses, and valves, all of which must remain sealed and protected to operate efficiently. One often-overlooked yet essential component in ensuring the longevity and performance of these systems is the hydraulic flange cap.

Hydraulic flange caps serve as protective covers for the open ends of hydraulic flanges. They prevent contaminants from entering the system, assist in safe transportation and storage, and support system maintenance by minimizing fluid leaks and pressure loss.

In this blog post, we’ll take a deep dive into the types, materials, and applications of hydraulic flange caps, so you can better understand their role and how to select the right one for your needs.

What Are Hydraulic Flange Caps?

Hydraulic flange caps are designed to cover and seal the ends of hydraulic flanges. They act as a barrier against external elements like:

➡️ Dust

➡️ Dirt

➡️ Moisture

➡️ Other contaminants

By shielding exposed flange connections, these caps help maintain system cleanliness, especially during transport or when the equipment is not in use.

In addition, they:

➡️ Support safe handling and storage of components

➡️ Reduce the risk of fluid leakage or contamination

➡️ Help maintain pressure integrity when systems are temporarily offline

When and Why They’re Used

Hydraulic flange caps are widely used in several scenarios:

➡️ Transportation: To prevent contaminants from entering open connections

➡️ System shutdowns: To maintain cleanliness and integrity when the system is offline

➡️ Flushing and cleaning: During maintenance to isolate parts of the system

➡️ Storage: To ensure parts are protected during downtime

Their use can extend the life of hydraulic equipment by preserving component quality and preventing early wear.

Types of Hydraulic Flange Caps

Hydraulic flange caps come in various types, each tailored for specific applications and sealing needs.

Threaded Flange Caps

These are screw-on type caps designed for high-pressure or long-term sealing. They are commonly used in:

1. Mobile hydraulic equipment

2. Industrial machinery

3. High-pressure environments where a secure fit is essential

Threaded caps are more robust and typically suited for semi-permanent or permanent protection.

Push-Fit Flange Caps

Push-fit caps are designed for quick and easy installation, making them ideal for temporary use. They’re typically used for:

1. Shipping protection

2. Short-term storage

3. Temporary system shutdowns

They don’t require tools for application or removal, which makes them efficient for fast-paced operations.

Dust Caps vs. Sealing Caps

1. Dust Caps: Focused on blocking contamination, ideal for low-pressure environments or where fluid containment isn’t needed.

2. Sealing Caps: Offer a tight seal to retain pressure and prevent leaks, used in systems where pressure retention is essential.

Custom or Specialty Flange Caps

Some applications demand unique features, and custom or specialty flange caps are made to meet these needs. Examples include:

➡️ High-temperature resistant caps

➡️ Color-coded caps for system identification

➡️ Tamper-proof caps for security in regulated environments

➡️ OEM-specific designs for proprietary equipment

Materials Used in Hydraulic Flange Caps

The performance and durability of a flange cap are heavily influenced by the material used. Here’s a breakdown of common options:

Plastic (Nylon, Polyethylene, Polypropylene)

➡️ Lightweight and corrosion-resistant

➡️ Best for temporary protection

➡️ Suitable for most environments unless extreme heat or pressure is involved

➡️ Cost-effective and recyclable

Plastic flange caps are ideal for businesses looking for economical, disposable solutions during transport or storage.

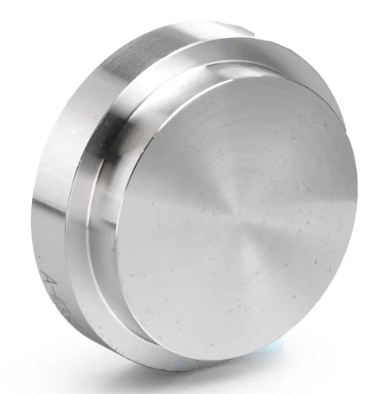

Metal (Steel, Stainless Steel, Aluminum)

➡️ Highly durable and suitable for high-pressure systems

➡️ Withstands extreme temperatures and chemical exposure

➡️ Ideal for permanent or long-term applications

➡️ Common in industrial, marine, and offshore settings

Stainless steel versions are especially favored where corrosion resistance is crucial.

Rubber and Elastomeric Compounds

➡️ Flexible and shock-absorbing

➡️ Offer superior sealing properties

➡️ Used in dynamic applications where some movement or vibration is expected

➡️ Suitable for equipment with irregular flange surfaces

➡️ Elastomeric caps are often used in automotive, aerospace, or mobile machinery.

Applications Across Industries

Hydraulic flange caps are found across a wide spectrum of industries, each with specific protection needs.

Construction and Heavy Equipment

1. Shields exposed hydraulic parts from mud, dust, and moisture

2. Used during transportation of excavators, bulldozers, and cranes

3. Essential for outdoor environments with harsh working conditions

Agriculture and Farming Machinery

1. Protects hydraulic lines in tractors, harvesters, and sprayers

2. Useful in dusty or muddy fields

3. Makes quick maintenance and equipment swaps easier and cleaner

Manufacturing and Automation

1. Applied during machine assembly, maintenance, or shutdowns

2. Helps prevent dust or debris from contaminating sensitive hydraulic systems

3. Supports clean production environments

Marine and Offshore

1. Used in saltwater-exposed systems like ships, oil rigs, and ports

2. Corrosion-resistant materials are key here

3. Often part of maintenance kits for onboard hydraulic systems

Aerospace and Defense

1. Requires high-performance flange caps

2. Must withstand extreme temperatures and pressures

3. Used in aircraft hydraulics and military ground vehicles

Choosing the Right Flange Cap

Selecting the right flange cap depends on several factors:

➡️ Environment: Will the cap face extreme temperatures, vibration, or chemical exposure?

➡️ System Pressure: High-pressure systems need more durable materials (e.g., metal or high-performance elastomers)

➡️ Flange Standard: Match the cap to standard sizes like SAE, ISO, or DIN

➡️ Material Preference: Choose based on required strength, reusability, and budget

➡️ Color-Coding or Labeling: Helps in organization and maintenance identification

By considering these, you’ll ensure optimal protection and system longevity.

Final Thoughts

Though often small and inexpensive, hydraulic flange caps play a big role in protecting your equipment and maintaining the integrity of your hydraulic systems. Whether you’re storing machinery, transporting equipment, or performing regular maintenance, choosing the right cap—by type, material, and application—can prevent costly damage and downtime.

Looking for quality hydraulic flange caps?

Browse our Hydraulic Flange Cap Range or contact our team for expert advice on the best options for your system.

Protect your investment! Cap it right!

Post time: Jul-30-2025