Hydraulic systems are the backbone of many industries, powering equipment in manufacturing plants, construction sites, agricultural operations, and mobile machinery. From lifting heavy loads to enabling precise motion control, hydraulics make modern operations efficient and reliable. However, when hydraulic systems fail, the consequences can be severe.

Hydraulic failures are costly due to unexpected downtime, safety hazards, expensive repairs, and reduced equipment lifespan. A single failure can halt production, delay projects, or even lead to workplace accidents.

The purpose of this article is to explain the most common types of hydraulic failures, how they occur, the warning signs to look for, and, most importantly, practical strategies to prevent them. Understanding these issues helps operators and maintenance teams keep systems running smoothly and avoid avoidable breakdowns.

How Hydraulic Systems Work (Brief Overview)

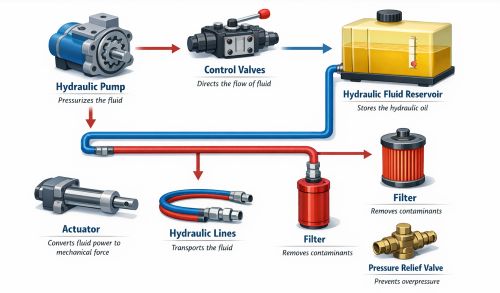

A hydraulic system uses pressurized fluid to transmit power and perform mechanical work. While systems vary in size and complexity, most include the following core components:

Basic Components of a Hydraulic System

1. Pump – Transfers fluid through the system to transform mechanical energy into hydraulic energy.

2. Hydraulic Fluid – Transmits electricity, disperses heat, lubricates parts, and guards against corrosion.

3. Valves – Control pressure, direction, and flow of the hydraulic fluid.

4. Cylinders and Motors – Convert hydraulic energy into linear or rotational mechanical motion.

5. Hoses and Seals – Transport fluid and maintain system pressure while preventing leaks.

Importance of Pressure, Flow, and Cleanliness

Hydraulic systems rely on the correct balance of pressure and flow to operate efficiently. Clean fluid is equally critical; contamination is one of the leading causes of system failure. Even minor deviations in these factors can cause performance issues.

Why Small Issues Escalate into Major Failures

Most hydraulic failures don’t happen suddenly. They start as small, unnoticed problems, slight contamination, a small leak, or marginal overheating, that worsen over time. Without early intervention, these issues compound and eventually lead to complete system failure.

Common Types of Hydraulic Failures

1. Hydraulic Fluid Contamination

Contamination occurs when unwanted substances enter the hydraulic fluid, degrading system performance.

Types of Contamination

➡️ Particulate: Dirt, dust, metal shavings

➡️ Water: Condensation, leaks, poor storage

➡️ Air: Entrained or dissolved air

Common Causes

➡️ Poor filtration

➡️ Improper maintenance practices

➡️ Contaminated replacement fluid

Warning Signs

➡️ Erratic operation

➡️ Increased wear

➡️ Noisy pumps and valves

Prevention Strategies

➡️ Use high-quality filtration systems

➡️ Practice clean fluid handling and storage

➡️ Perform regular fluid analysis

2. Hydraulic Fluid Degradation

Fluid degradation happens when hydraulic fluid breaks down chemically or physically over time.

Causes

1. Excessive heat

2. Oxidation

3. Extended service life

Impact on Performance

1. Reduced lubrication

2. Increased friction and wear

3. Formation of sludge and varnish

Symptoms

1. Darkened or foul-smelling fluid

2. Increased operating temperatures

3. Sluggish system response

Prevention Strategies

1. Monitor fluid temperature

2. Follow scheduled fluid replacement intervals

3. Use the correct fluid specifications recommended by manufacturers

3. Leakage (Internal and External)

Leakage is the unintended loss of hydraulic fluid within or outside the system.

Types of Leaks

➡️ Internal leaks: Fluid bypasses components internally, reducing efficiency

➡️ External leaks: Fluid escapes through fittings, hoses, or seals

Common Leak Points

➡️ Hoses

➡️ Fittings

➡️ Seals

➡️ Valves

Effects

➡️ Loss of system efficiency

➡️ Environmental hazards

➡️ Safety risks such as slips or fire hazards

Prevention Strategies

➡️ Conduct regular inspections

➡️ Select proper seals and materials

➡️ Ensure correct installation torque and alignment

4. Cavitation and Aeration

➡️ Cavitation: Formation and collapse of vapor bubbles due to low pressure

➡️ Aeration: Air entering the hydraulic fluid

Damage Caused

1. Pitting of pump surfaces

2. Reduced efficiency

3. Accelerated component wear

Symptoms

1. Loud knocking or whining noises

2. Vibration

3. Reduced system performance

Prevention Strategies

1. Design and maintain proper reservoirs

2. Maintain correct fluid levels

3. Eliminate air leaks in suction lines

5. Overheating

Overheating occurs when hydraulic fluid temperature exceeds safe operating limits.

Common Causes

➡️ Excessive pressure

➡️ Inadequate cooling

➡️ Internal leakage

Effects

➡️ Fluid breakdown

➡️ Seal hardening or failure

➡️ Reduced component life

Symptoms

1. Hot surfaces

2. Reduced efficiency

3. Burnt-smelling fluid

Prevention Strategies

1. Install effective cooling systems

2. Maintain correct pressure and flow settings

3. Perform routine system monitoring

6. Pump Failure

Pump failure results in reduced or complete loss of hydraulic power.

Common Failure Modes

1. Wear and scoring

2. Bearing failure

3. Seal damage

Causes

1. Contamination

2. Misalignment

3. Cavitation

Early Warning Signs

1. Noise and vibration

2. Pressure loss

3. Increased operating temperature

Prevention Strategies

1. Ensure correct pump sizing

2. Perform alignment checks

3. Implement preventive maintenance programs

7. Valve Malfunctions

Valves regulate flow, pressure, and direction. When they fail, system control is compromised.

Common Issues

➡️ Sticking valves

➡️ Wear

➡️ Contamination buildup

System Impact

➡️ Erratic motion

➡️ Pressure instability

➡️ Reduced efficiency

Prevention Strategies

➡️ Maintain clean fluid practices

➡️ Perform periodic testing and calibration

➡️ Replace worn components promptly

8. Seal and Hose Failure

Seals and hoses deteriorate over time, leading to leaks or sudden ruptures.

Causes

1. Aging materials

2. Chemical exposure

3. Excessive pressure

Environmental and Operational Factors

1. Extreme temperatures

2. Abrasion

3. Improper routing

Safety Risks

1. High-pressure fluid injection injuries

2. Fire hazards

3. Environmental contamination

Prevention Strategies

1. Use properly rated components

2. Avoid excessive bending and abrasion

3. Follow scheduled replacement cycles

General Best Practices to Prevent Hydraulic Failures

1. Implement a preventive maintenance schedule

2. Train operators and maintenance personnel

3. Use condition monitoring tools (fluid analysis, vibration monitoring)

4. Keep accurate maintenance records

5. Follow manufacturer recommendations consistently

Cost of Ignoring Hydraulic Failures

Ignoring hydraulic issues can result in:

1. Unplanned downtime and lost productivity

2. Safety hazards and regulatory non-compliance

3. Long-term equipment damage and higher repair costs

Example Scenario:

A small undetected fluid leak leads to contamination and pump failure. The result: halted production, emergency repairs, replacement parts, and lost revenue—costing many times more than routine maintenance would have.

When to Seek Professional Help

Situations Requiring Expert Diagnosis

➡️ Recurring failures

➡️ Unexplained pressure or temperature fluctuations

➡️ Complex system performance issues

Benefits of Professional Hydraulic Audits

➡️ Early problem detection

➡️ Optimized system performance

➡️ Reduced long-term costs

Importance of Qualified Technicians

Certified professionals ensure repairs and adjustments are done correctly, safely, and in compliance with industry standards.

Frequently Asked Questions (FAQ)

Q: What is the most common cause of hydraulic failure?

A: Fluid contamination is the leading cause of hydraulic system failure.

Q: How often should hydraulic fluid be analyzed?

A: Typically every 3–6 months, depending on operating conditions.

Q: Can overheating permanently damage a hydraulic system?

A: Yes, prolonged overheating can degrade fluid and destroy seals and components.

For more knowledge about your hydraulic system needs, check out these resources:

What Are Pneumatic Fitting Connectors and How Do They Work?

Why 90 Degree Compression Fittings Are Ideal for Tight Spaces

What Is a Hydraulic Plug with O Ring? Features and Advantages Explained

Conclusion

Hydraulic failures ranging from contamination and overheating to pump, valve, and hose failures are often preventable. Most issues begin small but escalate when left unchecked.

Prevention is far more effective and economical than repair. By adopting proactive maintenance practices, monitoring system conditions, and addressing problems early, organizations can ensure reliable performance, improved safety, and significant cost savings over the life of their hydraulic systems.

For durable and trusted hose fittings and adapters, contact Sannke!

Post time: Jan-29-2026