Identifying hydraulic fittings can be challenging, especially when multiple fittings look similar at first glance. Among the most commonly used types are JIC fittings, known for their reliability and compatibility across many hydraulic applications. Misidentifying these fittings can lead to leaks, downtime, or even equipment damage. That’s why understanding how to correctly identify JIC fittings is essential for anyone working with hydraulic or fluid systems.

In this guide, you’ll learn exactly how to identify JIC fittings by examining their flare angle, thread type, and thread size. We’ll also cover how JIC compares to similar fittings and what tools you need to ensure accurate identification.

What Is a JIC Fitting?

JIC fittings are precision-machined, mechanical flare fittings commonly used in high-pressure hydraulic applications. They were standardized by the Joint Industry Council, hence the name “JIC.” Their defining feature is the 37-degree flare that creates a metal-to-metal seal.

Common Applications

JIC fittings are widely used in:

➡️ Hydraulic systems

➡️ Fuel delivery lines

➡️ Industrial machinery

➡️ Agricultural equipment

➡️ Heavy equipment and construction machinery

Their durability and versatility make them a standard choice in industries where reliable sealing and vibration resistance are crucial.

Key Characteristic: 37-Degree Flare Sealing Surface

The most important feature of a JIC fitting is its 37° flare. This flare, when paired with a matching male or female seat, forms a tight, metal-to-metal seal without requiring an O-ring or gasket.

Comparison to Other Common Fittings

JIC fittings are often confused with:

1. NPT (National Pipe Tapered) fittings, which rely on tapered threads—not a flare— for sealing.

2. ORB (O-Ring Boss) fittings, which use straight threads but seal via an O-ring.

3. BSPP/BSPT (British Standard Pipe) fittings, which use different thread profiles and often a 60° seat.

Understanding these differences is key to identifying JIC fittings correctly.

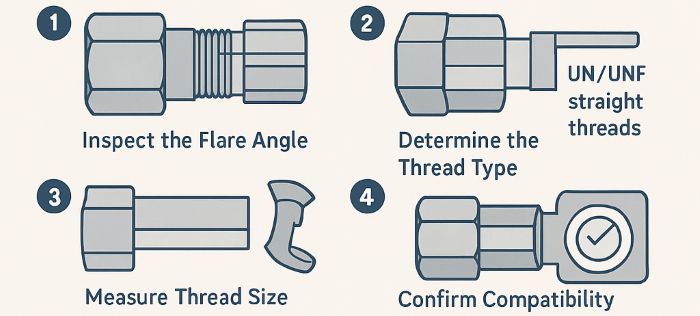

How to Identify JIC Fittings Step by Step

Step 1: Inspect the Flare Angle

JIC fittings use a 37-degree flare, which gives them their distinctive sealing surface. This angle is not interchangeable with other flare fittings, especially the more common 45-degree flare often found in automotive applications.

A 37° flare appears more shallow than a 45° flare. Experienced technicians can often see the difference by eye, but beginners should use a tool for accuracy.

A flare seat gauge is the most reliable way to confirm the flare angle. Simply place the gauge against the sealing surface and verify whether it matches the 37° profile.

Step 2: Determine the Thread Type

All JIC fittings use Unified National Fine (UNF) straight threads. This means:

➡️ Threads are not tapered

➡️ The seal does not occur on the threads

➡️ Thread pitch matches standardized UNF specifications

Recognizing Straight vs. Tapered Threads

➡️ Straight threads (JIC, ORB) maintain the same diameter across the length.

➡️ Tapered threads (NPT) get narrower toward the tip.

A quick visual inspection or a caliper measurement at two points will reveal whether the thread is straight.

Common Thread Pitches for JIC Fittings

Thread pitch varies based on size, but JIC threads are always UN/UNF. Examples include:

1. 1/4″ JIC: 7/16″-20

2. 3/8″ JIC: 9/16″-18

3. 1/2″ JIC: 3/4″-16

Step 3: Measure Thread Size

Tools You Need:

1. Digital or dial calipers

2. Thread pitch gauge

3. JIC size chart

These tools ensure accuracy and eliminate guesswork.

How to Measure Thread Dimensions

➡️ Male fittings: measure the outside diameter of the threads

➡️ Female fittings: measure the inside diameter of the threads

Next, use a thread pitch gauge to determine the number of threads per inch (TPI).

Matching Measurements to Size Charts

Once you have diameter + pitch, compare your measurements with a JIC chart. For example:

➡️ A male thread measuring ~0.56″ OD with 18 TPI corresponds to 3/8″ JIC.

➡️ A 0.75″ OD with 16 TPI corresponds to 1/2″ JIC.

Common JIC Sizes

1. 1/4″ — 7/16”-20

2. 3/8″ — 9/16”-18

3. 1/2″ — 3/4”-16

4. 3/4″ — 1-1/16”-12

5. 1″ — 1-5/16”-12

Step 4: Confirm Compatibility

Check Both Ends of the Fitting

Adapters may combine different fitting types. Always measure both ends—never assume they’re the same.

Ensure All Characteristics Match JIC Specs

For a fitting to be JIC:

➡️ The flare must be 37°

➡️ Threads must be UNF straight threads

➡️ Dimensions must match a JIC size

Warning: Don’t Mix JIC with AN or SAE

AN and JIC are similar but not identical. Mixing them incorrectly can cause:

➡️ Leaks

➡️ Thread galling

➡️ Safety hazards

Always verify the specification before installation.

JIC vs. Similar Fittings (How Not to Get Confused)

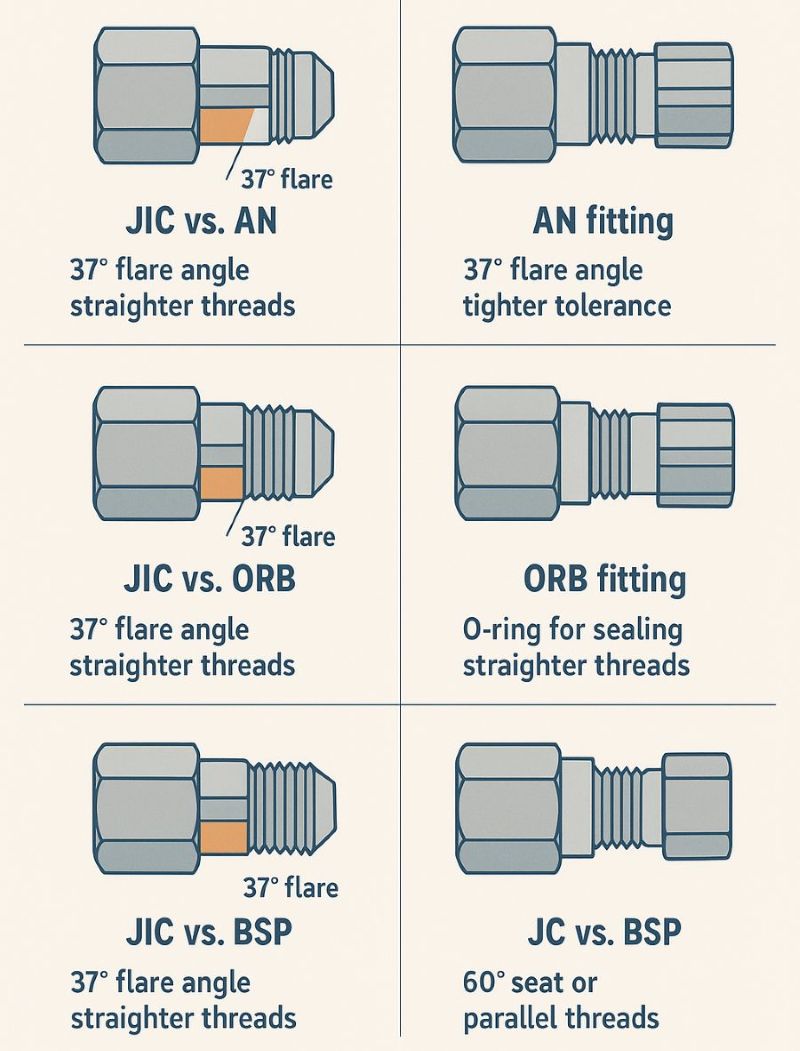

JIC vs. AN (Army-Navy) Fittings

Similarities

➡️ Both use 37° flare

➡️ Threads are very similar

Differences

➡️ AN fittings have tighter tolerances

➡️ Designed for aerospace and high-vibration environments

Why You Should Not Interchange Them

They may appear to fit together, but mismatched tolerances can lead to long-term reliability issues.

JIC vs. NPT Fittings

➡️ NPT uses tapered threads

➡️ Seals via thread deformation, often requiring tape or sealant

➡️ No flare seat

This makes NPT easy to distinguish once you recognize the tapers.

JIC vs. ORB (O-Ring Boss)

➡️ ORB uses straight threads, just like JIC

➡️ But it seals with an O-ring, not a flare

➡️ The absence of a flare seat makes ORB easy to spot

JIC vs. BSP Fittings

➡️ BSP threads have a different angle, pitch, and profile

➡️ Some BSP fittings have a 60° seat

Others use parallel threads

Quick ways to verify:

➡️ Use thread pitch gauge (BSP values differ)

➡️ Check for a 60° or flat seat instead of 37°

Tools You Need for Identifying JIC Fittings

To identify fittings accurately, use:

➡️ Thread pitch gauge — to determine TPI

➡️ Calipers — for measuring diameters

➡️ Flare angle gauge — to confirm the 37° seat

➡️ Comparison chart — to match measurements

Why Accuracy Matters

Incorrect fittings can lead to:

➡️ Hydraulic leaks

➡️ Pressure loss

➡️ Equipment failure

➡️ Increased maintenance costs

Precision is not optional in hydraulic systems, it’s essential.

Common Mistakes and How to Avoid Them

1. Assuming all straight threads are JIC — ORB also uses straight threads

2. Confusing 45° flare with 37° flare — always use a gauge

3. Not inspecting both ends of adapter fittings — mismatches are common

4. Ignoring thread damage — worn threads can distort measurements

JIC Size Chart

Here is a simplified JIC reference chart:

|

JIC Dash Size |

Thread Size (UNF) |

Male OD (inches) |

Common Applications |

|

-4 |

7/16”-20 |

0.44 |

Small hydraulics, fuel lines |

|

-6 |

9/16”-18 |

0.56 |

Medium pressure lines |

|

-8 |

3/4”-16 |

0.75 |

General hydraulic systems |

|

-12 |

1-1/16”-12 |

1.06 |

High-flow industrial hydraulics |

|

-16 |

1-5/16”-12 |

1.31 |

Heavy equipment and high-pressure use |

Note: Chart values are approximate and may vary by manufacturer

Conclusion

Identifying JIC fittings doesn’t have to be complicated. By focusing on three main features, flare angle, thread type, and thread size, you can quickly and accurately determine whether a fitting is JIC. Using the right tools, like calipers and thread gauges, ensures consistent and reliable results.

Proper identification prevents leaks, maintains system integrity, and ensures compatibility across your hydraulic components.

Post time: Nov-14-2025