When it comes to maintaining machinery, proper lubrication is everything. Without it, moving parts grind, overheat, and fail long before their expected lifespan. That’s where grease fittings come in, small but essential components that make lubrication fast, clean, and efficient.

In this guide, we’ll explore what a grease fitting is, how it works, the different types and materials available, and why they’re indispensable in mechanical systems. By the end, you’ll have a clear understanding of their purpose, operation, and maintenance.

What Is a Grease Fitting?

A grease fitting, also known as a Zerk fitting or grease nipple. It is a small metal connector designed to feed lubricant directly into mechanical systems such as bearings, joints, or bushings.

When a grease gun attaches to the fitting, it delivers pressurized grease into the internal lubrication channels of the equipment. This ensures every moving surface receives the necessary film of grease to reduce friction and wear.

In essence, grease fittings act as one-way valves, allowing grease in but keeping dirt, dust, and contaminants out. Their presence can dramatically extend the lifespan of machinery by preventing metal-to-metal contact and premature failure.

How Does a Grease Fitting Work?

Here’s how a grease fitting functions step-by-step:

1. A grease gun attaches securely to the head of the fitting.

2. Grease is pumped under pressure through the fitting’s internal check valve.

3. The lubricant travels through small internal passages, reaching bearings, bushings, or joints.

4. Inside the fitting, a check ball or spring-loaded valve opens to allow grease in and then closes immediately after, preventing grease from leaking out and contaminants from entering.

This simple yet effective mechanism maintains internal pressure and ensures a clean, controlled lubrication process. The result? Consistent protection, minimal mess, and extended component life.

Types of Grease Fittings

Grease fittings come in several shapes and designs to suit different maintenance needs and installation locations:

➡️ Standard (Straight) Fittings: The most common type, ideal for easily accessible points on machinery.

➡️ 90-Degree Fittings: Perfect for tight spaces or angled locations where a straight fitting would be hard to reach.

➡️ Button-Head Fittings: Used in heavy equipment and high-volume lubrication systems. Their large heads allow greater grease flow and easier connection in dirty or rugged environments.

➡️ Flush Grease Fittings: Designed for areas with limited clearance; they sit almost level with the surface to avoid snagging or damage.

Comparison Table: Fitting Types & When to Use Them

|

Fitting Type |

Description |

Ideal Application |

|

Straight (Standard) |

Basic, straight-in fitting. |

Easy-to-access lubrication points |

|

90° (Angle) Fitting |

Head is bent at 90°, allowing access in tight areas |

Spaces where gun access is obstructed |

|

Button-Head Fitting |

Large, low-profile head—often heavy-duty |

Heavy equipment, large bearings, rugged use |

|

Flush Grease Fitting |

Sits nearly flush with surface |

Areas with very limited clearance |

Comparison Table: Thread Sizes & Standards

|

Standard Type |

Common Thread Example |

Diameter & Pitch Example |

Notes |

|

SAE (Imperial) |

¼″-28 UNF |

~0.25″ diameter, 28 threads/inch |

Very common in North America |

|

Metric |

M6 × 1.0 |

6 mm diameter, 1.0 mm pitch |

Used in Europe/Asia & metric-based systems |

|

Metric |

M8 × 1.0 |

8 mm diameter, 1.0 mm pitch |

Medium-duty industrial applications |

|

BSP / Pipe |

1/8″ BSPT |

Tapered pipe thread |

Older industrial / fluid systems |

Grease Fitting Size Chart

|

Thread Type |

Thread Size |

Common Name |

Thread Pitch |

Typical Application |

Notes |

|

SAE (Inch) |

1/4″-28 UNF |

Standard (SAE-LT) |

Fine Thread |

Automotive, light machinery |

Most common in North America |

|

SAE (Inch) |

1/8″-27 NPT |

Pipe Thread |

Tapered |

Heavy equipment, hydraulic systems |

Provides tight seal for high pressure |

|

SAE (Inch) |

5/16″-24 UNF |

Fine Thread |

Fine |

Industrial and agricultural use |

Used when stronger threads are needed |

|

SAE (Inch) |

3/8″-24 UNF |

Fine Thread |

Fine |

Construction and mining equipment |

Common on large bearings |

|

Metric |

M6 × 1.0 |

Metric Fine |

1.0 mm |

European vehicles, small bearings |

Standard for compact fittings |

|

Metric |

M8 × 1.0 |

Metric Fine |

1.0 mm |

General industrial use |

Often replaces 1/4″-28 in EU machinery |

|

Metric |

M10 × 1.0 |

Metric Fine |

1.0 mm |

Heavy-duty machinery |

Suitable for higher torque applications |

|

BSP (British Standard Pipe) |

1/8″ BSPT |

Pipe Thread (Tapered) |

28 TPI |

UK and Commonwealth equipment |

Seals well under pressure |

|

BSP (British Standard Pipe) |

1/4″ BSPT |

Pipe Thread (Tapered) |

19 TPI |

Marine and industrial systems |

Used in larger lubrication lines |

|

Material |

Properties |

Best Used For |

|

Steel (Zinc-Plated) |

Strong, affordable, corrosion-resistant |

General-purpose machinery |

|

Brass |

Corrosion-resistant, softer metal |

Light-duty or precision equipment |

|

Stainless Steel |

Highly corrosion-resistant |

Marine, food processing, chemical environments |

|

Carbon Steel |

Strong but less corrosion-resistant |

Indoor or dry conditions |

Quick Selection Checklist

➡️ Measure the existing thread diameter and pitch to determine whether it’s SAE or Metric.

➡️ Choose the fitting type (straight, 90°, button‐head, flush) based on accessibility and space constraints.

➡️ Select the material (steel / zinc-plated, brass, stainless) appropriate for the environment (e.g., corrosion‐resistant for marine).

➡️ Verify the fitting’s head size / profile to ensure your grease gun can couple properly.

➡️ Ensure the fitting is rated / compatible for your grease type, pressure, and equipment load.

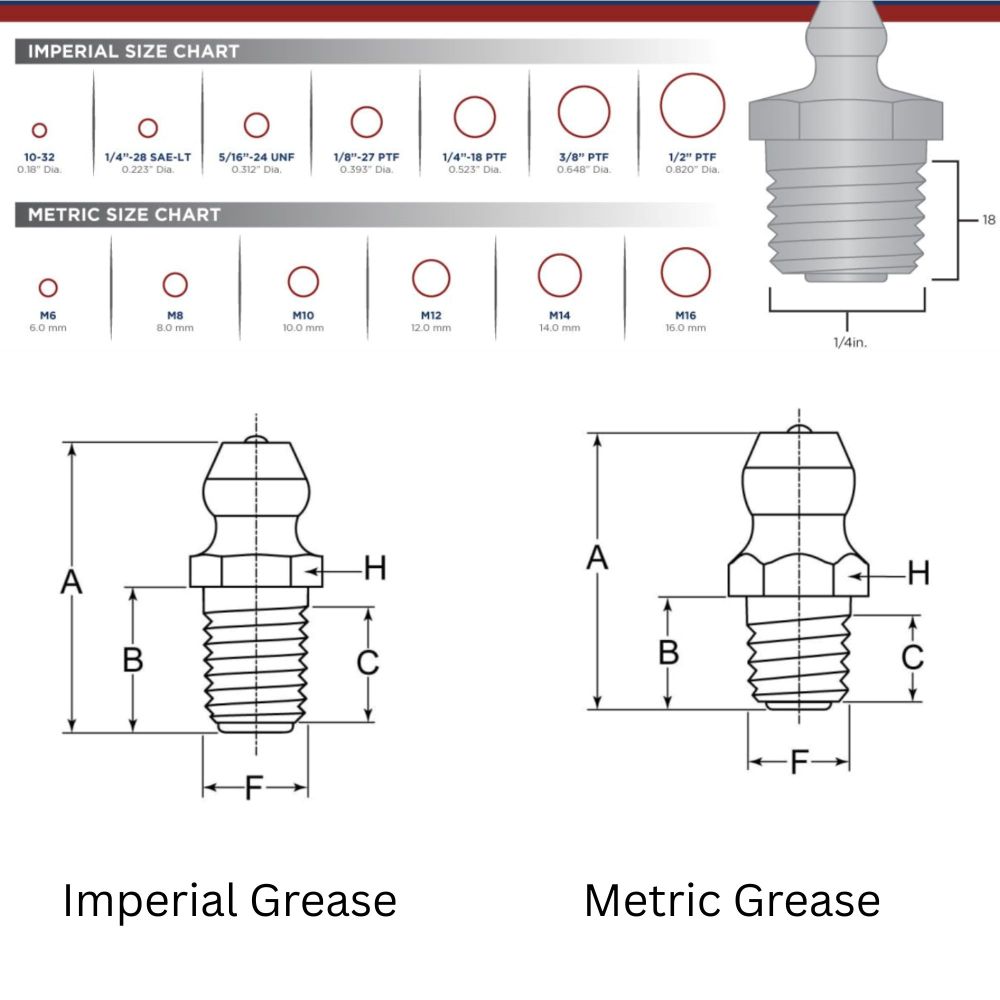

Grease-fitting Thread Styles (SAE vs Metric)

Key Points from the Diagram

➡️ On the left you’ll see the SAE/Imperial thread sizes (for example: ¼″-28 UNF) — common in North American machinery.

➡️ On the right you’ll see Metric thread versions (for example: M6 × 1.0, M8 × 1.0) — common in European/Asian machinery and many newer systems.

➡️ The diagrams highlight differences in thread diameter, pitch (threads per inch or mm between threads), and nipple / head profile for the fitting.

Note: Despite similar external appearance, SAE and Metric fittings are not interchangeable, because the threads don’t match in size or pitch.

Applications of Grease Fittings

Grease fittings are used virtually everywhere mechanical motion exists. Common applications include:

1. Automotive: Suspension joints, drive shafts, and steering linkages.

2. Agriculture: Tractors, combines, and other farm implements.

3. Construction and Industrial Equipment: Excavators, loaders, and conveyor systems.

4. Marine and Aviation: Control linkages and mechanical joints exposed to moisture or vibration.

Their versatility and reliability make them essential across all sectors where machinery depends on consistent lubrication.

Common Problems and Maintenance Tips

Even the best grease fittings need occasional attention. Here are a few common issues and how to handle them:

1. Clogged Fittings: Dirt or hardened grease can block flow. Clean the fitting tip with a wire brush or replace it if necessary.

2. Over-Greasing: Too much grease can damage seals or create excessive pressure. Pump only until slight resistance or grease appears at the relief point.

3. Contamination: Always wipe the fitting before connecting the grease gun to prevent debris from entering the system.

Maintenance Tip: Use the correct grease type recommended for your machinery, and ensure your grease gun delivers clean, uncontaminated lubricant.

Advantages of Using Grease Fittings

1. Provide easy, efficient access for lubrication.

2. Prevent wear, corrosion, and failure of critical components.

3. Reduce downtime and lower maintenance costs.

4. Extend equipment life, improving overall performance and reliability.

With regular use and proper care, grease fittings become one of the simplest ways to protect your investment in machinery.

Conclusion

Grease fittings may be small, but their impact is significant. They ensure that essential moving parts receive the lubrication they need to operate smoothly and last longer.

By understanding their function, types, and maintenance, you can keep your machinery running efficiently and avoid costly breakdowns.

Choose high-quality grease fittings and inspect them regularly, it’s a small step that makes a big difference in performance and longevity.

FAQs

Q1: Can I reuse old grease fittings?

You can, but only if they’re clean and not clogged or damaged. Replacing worn or corroded fittings is inexpensive insurance against future issues.

Q2: How often should I lubricate through a grease fitting?

Follow your manufacturer’s maintenance schedule. Frequency depends on operating conditions, load, and environment, heavy-duty or outdoor machines may need more frequent greasing.

Q3: What’s the difference between Zerk and button-head fittings?

A Zerk fitting is a standard nipple-type fitting for general use, while a button-head fitting has a larger head for high-volume or heavy-equipment lubrication.

Q4: What tools do I need to service grease fittings?

You’ll need a grease gun, the appropriate grease, and possibly a fitting cleaner or replacement tool for maintenance.

Post time: Nov-11-2025