Proper thread compatibility is essential for safe and reliable hydraulic systems. Because hydraulic connections operate under high pressure and vibration, even small thread mismatches can cause leaks, pressure loss, or system failure.

Two common hydraulic thread types are G Pipe Thread (BSPP) and NPT (National Pipe Taper). Although they may look similar, they follow different standards and sealing methods and are not directly compatible.

This article explains the key differences between G Pipe Thread and NPT and what to consider to ensure proper hydraulic thread compatibility.

What Are Hydraulic Pipe Threads?

Hydraulic pipe threads are standardized helical grooves formed on the outside or inside of fittings, hoses, and ports. Their primary purpose is to connect components within a hydraulic system while maintaining a secure and pressure-resistant joint.

Threads play two important roles in hydraulics. First, they provide the mechanical connection, holding components together. Second, depending on the thread type, they may also contribute to the sealing function, preventing fluid from leaking under pressure. In some designs, the threads themselves create the seal, while in others, the seal is achieved using an O-ring, washer, or bonded seal.

It is important to understand that not all threads are designed to seal in the same way. This distinction is why international thread standards exist, such as BSP, NPT, JIC, and metric threads. Each standard defines thread geometry, angles, tolerances, and sealing methods to ensure consistency and safety across applications.

Overview of G Pipe Thread (BSPP)

What Is a G Pipe Thread?

A G Pipe Thread, also known as BSPP (British Standard Pipe Parallel), is a parallel (straight) pipe thread defined by British and international standards. The “G” designation refers specifically to the parallel version of BSP threads.

G threads are governed by standards such as ISO 228 and BS 2779, which define their dimensions and performance requirements. Unlike tapered threads, G threads do not seal on the threads themselves.

Key Characteristics of G Pipe Threads

G Pipe Threads feature a parallel thread design, meaning the diameter of the thread remains constant along its length. The thread form uses a 55-degree Whitworth profile, which is distinct from many other hydraulic thread types.

Because G threads are parallel, they require an external sealing method. Sealing is typically achieved using an O-ring, bonded seal (Dowty washer), or flat washer that compresses against a machined face. This design allows for consistent sealing without relying on thread deformation.

G threads are commonly manufactured in materials such as carbon steel, stainless steel, brass, and plated finishes like zinc or nickel, depending on corrosion resistance and application needs.

Typical Applications of G Threads

G Pipe Threads are widely used in European and Asian hydraulic systems. They are common in industrial machinery, hydraulic power units, pneumatic systems, and fluid transfer equipment. Many OEM manufacturers standardize on BSPP threads due to their reliable sealing and ease of maintenance.

Overview of NPT (National Pipe Taper) Threads

What Is NPT?

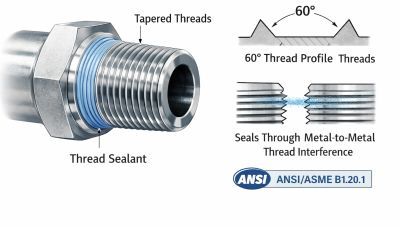

NPT, or National Pipe Taper, is a tapered pipe thread standard primarily used in North America. It is governed by ANSI/ASME B1.20.1, which defines its geometry and tolerances.

Unlike G threads, NPT threads are designed to seal through thread engagement and deformation.

Key Characteristics of NPT Threads

NPT threads have a tapered design, meaning the thread diameter gradually decreases along the length of the thread. This taper creates a tight, interference fit as the male and female threads are tightened together.

The thread angle for NPT is 60 degrees, which differs from BSPP’s 55-degree profile. Sealing occurs through metal-to-metal contact between the threads, often assisted by thread sealants such as PTFE tape or liquid thread compound to fill small gaps and improve sealing.

Typical Applications of NPT Threads

NPT threads are commonly found in North American hydraulic and fluid systems, including industrial equipment, agricultural machinery, construction equipment, and general-purpose fluid connections. They are widely available and familiar to technicians in these regions.

G Pipe Thread vs NPT: Key Differences

|

Feature |

G Pipe Thread (BSPP) |

NPT (National Pipe Taper) |

|

Thread Design |

Parallel (straight) thread |

Tapered thread |

|

Thread Angle |

55° Whitworth profile |

60° thread profile |

|

Sealing Method |

Seals with O-ring, bonded seal, or washer at the face |

Seals through metal-to-metal thread interference |

|

Use of Sealant |

Typically not required |

Commonly required (PTFE tape or thread compound) |

|

Pressure Performance |

More consistent and reliable for high-pressure hydraulics |

Pressure capability depends on installation and sealant |

|

Installation |

Threads engage fully without wedging |

Threads tighten progressively due to taper |

|

Risk of Over-Tightening |

Low, seal is independent of thread torque |

Higher risk of thread damage if over-tightened |

|

Standards |

ISO 228, BS 2779 |

ANSI/ASME B1.20.1 |

|

Regional Use |

Europe, Asia, international systems |

North America |

|

Typical Applications |

Hydraulic and pneumatic systems, OEM machinery |

General fluid systems, hydraulics, industrial equipment |

|

Interchangeability |

Not interchangeable with NPT |

Not interchangeable with G thread |

Are G Pipe Threads and NPT Threads Compatible?

G Pipe Threads and NPT threads are not directly compatible, even if they appear to fit initially. The differences in thread angle, taper, and sealing method make them unsuitable for direct connection.

Mixing these threads can result in poor sealing, damaged threads, and eventual leakage or system failure. A common misconception is that threads that “almost fit” are acceptable. In hydraulic systems, this assumption can lead to serious safety and reliability issues.

How to Identify G Pipe Thread vs NPT

Visual Inspection

Visually, G threads appear straight, while NPT threads are visibly tapered. Differences in thread pitch may also be noticeable when comparing similar sizes.

Measurement Techniques

Accurate identification requires measuring the thread angle and thread pitch using thread gauges. Calipers can also be used to check whether the thread diameter changes along its length.

Markings and Documentation

Manufacturer markings, part numbers, and equipment manuals often indicate the thread type. Reviewing technical documentation is one of the most reliable identification methods.

Solutions for Thread Compatibility Issues

When thread incompatibility arises, the safest solution is to use proper adapters or conversion fittings designed specifically to connect G threads to NPT threads. These adapters maintain correct thread geometry and sealing methods on both sides.

Selecting fittings with the correct sealing method and matching thread standards from the beginning helps prevent costly rework. Good system design and regular maintenance practices also reduce the risk of compatibility issues.

Best Practices for Choosing the Right Hydraulic Thread

Always consider system pressure, temperature, and application requirements before selecting a thread type. Follow regional standards and OEM specifications whenever possible. Avoid forcing connections between incompatible threads, and consult manufacturers or hydraulic specialists if there is any uncertainty.

Common Mistakes to Avoid

One of the most common mistakes is assuming G and NPT threads are interchangeable. Over-tightening threads to stop leaks can cause damage and worsen sealing problems. Ignoring sealing requirements or using incorrect adapters and sealants can also compromise system integrity.

Frequently Asked Questions

Can G Pipe Thread be used with NPT fittings?

No, they are not directly compatible and require a proper adapter.

Do G threads require sealant?

Typically no. G threads seal using an O-ring or washer, not thread sealant.

Which thread type is better for high-pressure hydraulics?

G threads often perform better in high-pressure systems due to controlled face sealing.

How can I convert G threads to NPT safely?

By using certified adapters designed specifically for G-to-NPT conversion.

Conclusion

G Pipe Thread and NPT are both widely used in hydraulic systems, but they differ significantly in design, sealing method, and standards. Understanding these differences is essential for ensuring safety, reliability, and optimal system performance.

Always verify thread compatibility before installation, use the correct fittings and adapters, and follow recognized standards. Taking the time to choose the right hydraulic thread will help prevent leaks, downtime, and costly failures in the long run.

Post time: Dec-17-2025