In hydraulic, pneumatic, and industrial systems, reliability often comes down to the quality of your connections. Tube fittings may seem like small components, but they’re critical for preventing leaks, resisting vibration, and ensuring consistent system performance. Because of this, choosing the right type of fitting is more than a minor design decision—it affects safety, efficiency, maintenance, and long-term system costs.

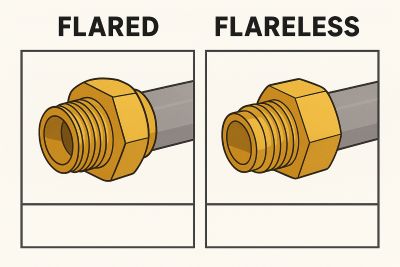

Among the most widely used tube connection types are flared and flareless fittings. While both are designed to deliver strong, leak-resistant connections, they function differently and excel in different environments. Understanding how each type works will help you make confident decisions when designing or maintaining fluid power systems.

What Are Flared Fittings?

Flared fittings use a simple but effective concept: the end of the tube is flared outward—typically at a 37° or 45° angle, so it can form a tight mechanical seal when compressed against the fitting body. This flare provides a strong mating surface, enhancing both sealing and structural integrity.

How Flared Fittings Are Made

To create a flared tube end, technicians use a flaring tool that reshapes the tubing. The process can vary:

➡️ Single-flare: A basic flare formed once at the required angle.

➡️ Double-flare: The tube end is folded and flared twice, adding strength and reducing the risk of cracking.

➡️ Angle options, include 37° (common in aerospace and hydraulics) and 45° (common in automotive and refrigeration)

Proper tooling and technique are essential to ensure a uniform flare that seals correctly.

Advantages of Flared Fittings

1. Leak resistance: The metal-to-metal seal is precise and highly reliable.

2. Strong vibration resistance: Ideal for applications exposed to continuous movement.

3. Reusability: Fittings can often be disassembled and reconstructed.

4. High-pressure capability: Excellent for systems operating under demanding pressure conditions.

Disadvantages of Flared Fittings

➡️ Requires precision during installation: Imperfect flares can lead to leaks or fitting damage.

➡️ Time-consuming prep work: Each tube must be cut, deburred, and flared accurately.

➡️ Less efficient for large-scale assembly: Not ideal for high-volume production where speed is essential.

Common Applications

Flared fittings are often found in:

1. Aerospace and aviation systems

2. Refrigeration and HVAC equipment

3. High-pressure hydraulic lines

4. Automotive fuel and brake systems

What Are Flareless Fittings?

Flareless fittings create a seal without requiring the tube end to be flared. Instead, they rely on compression or a “biting” action from ferrules inside the fitting.

How Flareless Fittings Are Made

A typical flareless fitting consists of:

➡️ Nut – secures the tube

➡️ Ferrule(s) – bite into or compress around the tubing

➡️ Body – contains the seating area and threads

There are two main types:

➡️ Compression-type: Ferrule(s) compress onto the outside of the tubing.

➡️ Bite-type: Ferrule bites into the tubing wall for a stronger grip, often used for higher pressures.

Advantages of Flareless Fittings

1. Faster, easier installation: No flaring tools or shaping required.

2. Ideal for field repairs: Great when you need to make quick connections or replacements.

3. No specialized tools needed: Reduces setup time and simplifies assembly.

4. Good performance in moderate–high pressure systems: Trusted in many industrial environments.

Disadvantages of Flareless Fittings

1. Not ideal for extreme vibration: Biting ferrules may loosen or wear over time.

2. Slightly higher leak risk compared to expertly installed flared fittings.

3. Tube preparation still matters: Clean, square cuts are essential for proper sealing.

Common Applications

Flareless fittings are widely used in:

➡️ Industrial hydraulic systems

➡️ Mobile equipment

➡️ Chemical processing systems

➡️ General fluid power applications

Key Differences Between Flared and Flareless Fittings

|

Category |

Flared Fittings |

Flareless Fittings |

|

Installation Requirements |

Requires precise flaring; more preparation and higher skill |

Simple tube preparation; faster installation; moderate skill |

|

Tools Needed |

Tube cutter, deburring tool, flaring tool, wrenches |

Basic hand tools (wrenches), no flaring tools |

|

Preparation Time |

Longer—tube must be shaped and flared to exact angle |

Shorter—cut tube, insert ferrule, tighten |

|

Pressure Rating |

Typically higher pressure capability |

Moderate to high pressure depending on ferrule type (compression vs. bite-type) |

|

Vibration Resistance |

Excellent—flare provides strong mechanical support |

Good—may require additional vibration control or clamping |

|

Leak Resistance |

Very high—metal-to-metal flare seal |

Good—depends on proper ferrule engagement |

|

Reusability |

Highly reusable |

Moderately reusable; ferrules may deform during tightening |

|

Installation Cost |

Lower fitting cost; higher labor cost |

Higher fitting cost; lower labor cost |

|

Best Use Cases |

High-pressure, high-vibration environments; aerospace; automotive; refrigeration |

Field repairs; industrial machinery; mobile equipment; systems needing fast assembly |

|

Industry Standards |

SAE J514 (37° flare), SAE J533, SAE J512 |

ISO 8434 / DIN 2353, SAE J514 O-ring, JIC flareless standards |

When to Use Flared Fittings

Use flared fittings when:

1. The system operates under high pressure

2. There is significant vibration

3. You need tight-seal performance, such as in brake or fuel lines

4. Applications involve aerospace or defense

5. You require reusability in maintenance cycles

When to Use Flareless Fittings

Choose flareless fittings if:

1. You need quick, efficient field installation

2. The system operates with moderate to high pressure

3. Frequent maintenance or component swaps are expected

4. No flaring tools are available

5. You’re working with large-diameter or thick-walled tubing

How to Choose the Right Fitting for Your Application

Ask These Key Questions

➡️ What is the pressure rating of the system?

➡️ Will the system experience continuous vibration?

➡️ Are field repairs likely or frequent?

➡️ What material is the tubing made from?

➡️ Is precision tooling available?

Practical Tips

➡️ Consider environmental conditions such as temperature and vibration.

➡️ Know the industry standards relevant to your equipment.

➡️ Review manufacturer data sheets for compatibility and specifications.

➡️ Always use the proper torque and installation techniques for consistent sealing.

Conclusion

Both flared and flareless fittings provide reliable tube connections, but their differences make each suitable for specific environments. Flared fittings shine in high-pressure, high-vibration scenarios where maximum sealing strength is essential. Flareless fittings, on the other hand, excel in quick-assembly, field-repair, and maintenance-heavy applications.

Choosing the best option depends on your system’s demands, the tools available, and the expertise of your installation team. When in doubt, consult reputable fitting manufacturers or experienced technical specialists to ensure the safest and most efficient solution for your application.

Post time: Nov-20-2025