Hydraulic systems power a wide range of industrial, automotive, and heavy-duty equipment by using pressurized fluid to transmit force. To operate safely and efficiently, these systems depend on strong, leak-free connections that can withstand high pressure, vibration, and temperature changes. Even a minor connection failure can cause fluid loss, reduced efficiency, safety risks, and unplanned downtime.

A hydraulic flare union is a common hydraulic fitting designed to create a secure, metal-to-metal seal between flared tubes. It plays a critical role in maintaining system reliability, pressure integrity, and ease of maintenance. Understanding how hydraulic flare unions work, where they are used, and how to install them correctly is essential for ensuring long-term performance and safety in hydraulic systems.

What Is a Hydraulic Flare Union?

A hydraulic flare union is a type of fitting designed to connect two flared tubes or hoses in a hydraulic system. It uses a flared tube end and a threaded union body to create a strong, metal-to-metal seal capable of withstanding high pressure.

Role in Hydraulic Fluid Transfer Systems

Hydraulic flare unions play a vital role in:

➡️ Connecting hydraulic lines securely

➡️ Maintaining consistent fluid flow

➡️ Preventing leaks under pressure and vibration

➡️ Allowing easy disassembly for maintenance or replacement

How Flare Unions Differ from Other Hydraulic Fittings

Unlike compression fittings or pipe fittings that rely on ferrules or thread sealants, flare unions seal through direct metal-to-metal contact. This makes them especially reliable in high-pressure applications where leaks cannot be tolerated.

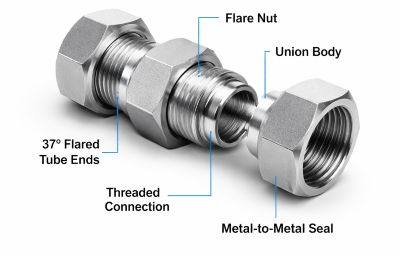

Main Components of a Hydraulic Flare Union

A hydraulic flare union consists of several key components working together:

Union Body

The main fitting that houses the connection and provides structural strength.

Flared Tube Ends

The ends of the hydraulic tube are flared outward at a specific angle to create the sealing surface.

Threaded Connections

Threads allow the union to be tightened securely, drawing the flared surfaces together.

Sealing Surfaces

The angled flare faces that come into contact to form a pressure-tight seal.

Common Materials Used

Hydraulic flare unions are typically made from:

1. Carbon steel – strong and cost-effective

2. Stainless steel – corrosion-resistant for harsh environments

3. Brass – suitable for lower-pressure or specialized applications

How Does a Hydraulic Flare Union Work?

The Flaring Process

Before installation, the tube end is flared using a flaring tool. This creates a smooth, angled surface that matches the union’s sealing angle.

Metal-to-Metal Sealing Principle

When assembled, the flared tube end mates with the corresponding cone inside the union. This direct metal contact creates the seal—no O-rings or sealants required.

How Tightening Creates a Pressure-Resistant Seal

As the threaded connection is tightened, axial force presses the flare firmly against the sealing surface. The tighter fit increases resistance to internal pressure.

Step-by-Step Connection Process

1. Cut and deburr the tube

2. Flare the tube end to the correct angle

3. Align the flared tube with the union

4. Thread the union nut by hand

5. Tighten to the specified torque

Types of Hydraulic Flare Unions

37-Degree Flare Unions (JIC Standard)

Commonly used in hydraulic systems, especially in industrial and mobile equipment.

45-Degree Flare Unions

Often found in automotive and low-pressure applications.

SAE Flare Unions

Meet Society of Automotive Engineers standards for specific applications.

Male-to-Male vs. Female-to-Female Unions

Different configurations allow flexibility in system design and connection requirements.

Applications of Hydraulic Flare Unions

Hydraulic flare unions are used across a wide range of industries:

1. Industrial hydraulic systems

2. Construction and heavy machinery

3. Automotive and transportation systems

4. Oil, gas, and energy industries

5. Agricultural equipment

Their reliability makes them suitable for both stationary and mobile hydraulic systems.

Advantages of Hydraulic Flare Unions

1. Leak-resistant sealing through metal-to-metal contact

2. High-pressure performance

3. Easy installation and disassembly

4. Reusability and long service life

5. Compatibility with various hydraulic fluids

Hydraulic Flare Union vs. Other Fitting Types

Flare Union vs. Compression Fitting

Compression fittings use ferrules, while flare unions rely on flared tube ends, making flare unions better for high-pressure systems.

Flare Union vs. O-Ring Face Seal (ORFS)

ORFS fittings use elastomer seals, while flare unions use metal sealing—each suited to different environments.

Flare Union vs. Pipe Fittings

Pipe fittings seal via threads and sealant, whereas flare unions provide more consistent sealing and easier maintenance.

When to Choose a Flare Union

Choose a flare union when high pressure, vibration resistance, and reusability are critical.

Installation Best Practices

1. Use proper tube flaring tools

2. Tighten to the manufacturer’s recommended torque

3. Ensure correct alignment before tightening

4. Inspect threads for damage

5. Avoid over-tightening

Common Problems and Troubleshooting

Causes of Leaks

➡️ Damaged flare surface

➡️ Incorrect flare angle

➡️ Loose or over-tightened connection

Damage from Over-Tightening

Excessive torque can deform the flare and ruin the seal.

Misalignment or Incorrect Flare Angle

Always match the union and flare standards.

Inspecting and Replacing Faulty Unions

Replace any fitting showing cracks, deformation, or severe corrosion.

Maintenance and Inspection Tips

1. Perform regular visual inspections

2. Clean fittings to prevent contamination

3. Protect against corrosion

4. Watch for signs of fatigue or wear

5. Follow recommended replacement intervals

How to Choose the Right Hydraulic Flare Union

Consider the following factors:

1. Size and thread compatibility

2. Pressure and temperature ratings

3. Material selection based on environment

4. Compliance with industry standards and certifications

Safety Considerations

1. Always depressurize systems before maintenance

2. Wear appropriate personal protective equipment

3. Handle hydraulic fluid leaks immediately

4. Ensure proper installation training

5. Follow industry safety standards and regulations

Frequently Asked Questions

Are hydraulic flare unions reusable?

Yes, if they are not damaged and the flare surface remains intact.

Can flare unions be used in high-pressure systems?

Yes, they are commonly used in high-pressure hydraulic applications.

What is the difference between 37-degree and 45-degree flare unions?

They differ in flare angle and application standards and are not interchangeable.

How do I know if my flare union is leaking?

Look for visible fluid seepage, pressure loss, or loose connections.

Conclusion

Hydraulic flare unions are essential components that provide strong, leak-resistant connections in hydraulic systems. By understanding how they work, their advantages, and proper installation practices, you can significantly improve system performance and safety.

Choosing the correct flare union and installing it properly ensures long-term reliability, reduced maintenance costs, and optimal hydraulic efficiency.

Post time: Dec-22-2025