Hydraulic fittings play a critical role in fluid power systems by connecting tubes, pipes, and hoses to ensure the safe and efficient transfer of hydraulic fluids. These fittings must withstand high pressure, vibration, and temperature changes while maintaining a leak-free seal. Among the many fitting types available, flare to flare hydraulic fittings are widely used for their reliability, strength, and reusability.

Flare to flare fittings are especially common in high-pressure hydraulic applications where metal-to-metal sealing is preferred. Understanding how these fittings work, where they are used, and how to install them correctly is essential for system safety, performance, and longevity.

In this guide, you will learn what flare to flare fittings are, how they function, the different flare standards, their advantages and limitations, installation best practices, and how to choose the right fitting for your hydraulic application.

What Are Flare to Flare Hydraulic Fittings?

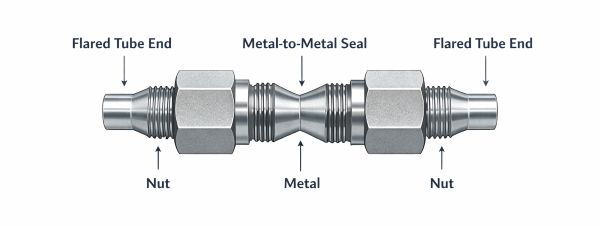

Flare to flare hydraulic fittings are connection components designed to join two flared tube ends together. The sealing surface is created by the contact between the flared ends of the tubing and the fitting body, forming a secure metal-to-metal seal.

How Flare to Flare Fittings Create a Seal

The seal is formed when the flared tube end is tightened against the mating cone of the fitting body. As torque is applied, the two flared surfaces compress together, preventing hydraulic fluid from escaping without the need for elastomeric seals.

Common Materials Used

Flare-to-flare fittings are typically manufactured from:

➡️ Carbon steel – strong, durable, and commonly used in industrial hydraulics

➡️ Stainless steel – resistant to corrosion and appropriate for challenging conditions.

➡️ Brass – often used in low-pressure or specialty applications

Typical Pressure and Temperature Ranges

These fittings are well-suited for medium to high-pressure systems and can handle wide temperature ranges, depending on material selection and system design. Steel and stainless steel versions are commonly used in high-pressure hydraulic circuits.

How Flare to Flare Fittings Work

1. Flared Tube End Design

The tube end is mechanically flared at a specific angle using a flaring tool. This flared surface is what mates with the fitting body to create the seal.

2. Metal-to-Metal Sealing Mechanism

Unlike fittings that rely on O-rings or seals, flare to flare fittings depend entirely on metal contact. This makes them highly resistant to heat, pressure, and chemical degradation.

3. Importance of Proper Torque and Alignment

Correct torque is essential. Under-tightening can cause leaks, while over-tightening may damage the flare or fitting body. Proper alignment ensures even contact between sealing surfaces.

4. Comparison With Other Sealing Methods

➡️ O-ring fittings: Use elastomer seals, excellent for zero-leak requirements

➡️ Compression fittings: Rely on ferrules to grip tubing

➡️ Welded connections: Permanent, high-strength joints

Flare fittings strike a balance between strength, reusability, and ease of maintenance.

Common Types of Flare Standards

1. 37° Flare (JIC Fittings)

➡️ Widely used in hydraulic systems

➡️ Defined by SAE standards

➡️ Designed for high-pressure applications

2. 45° Flare Fittings

➡️ Common in automotive and refrigeration systems

➡️ Typically lower pressure rated than 37° fittings

3. Differences Between 37° and 45° Flare Standards

The flare angle is the key difference. These fittings are not interchangeable, as mismatching angles can lead to leaks and fitting damage.

4. Compatibility and Interchangeability Considerations

Always verify flare angle, thread type, and standard before installation to avoid compatibility issues.

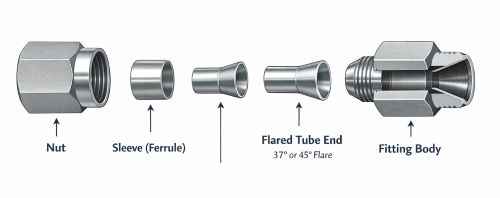

Key Components of Flare to Flare Fittings

1. Nut

Provides the clamping force needed to hold the flared tube tightly against the fitting body.

2. Sleeve (If Applicable)

Used in some designs to support the tube and improve alignment.

3. Flared Tube End

The primary sealing surface that contacts the fitting body.

4. Fitting Body

Contains the mating cone and threads that receive the nut.

Each component works together to ensure strength, sealing integrity, and pressure resistance.

Applications of Flare to Flare Hydraulic Fittings

Flare to flare fittings are used across a wide range of industries, including:

➡️ Industrial hydraulic machinery

➡️ Automotive and transportation systems

➡️ Agricultural equipment

➡️ Aerospace and marine applications

➡️ High-pressure fluid transfer systems

Their durability and vibration resistance make them ideal for demanding environments.

Advantages of Flare to Flare Fittings

1. Strong, leak-resistant metal-to-metal seal

2. Reusable and easy to disassemble

3. Suitable for high-pressure hydraulic systems

4. Excellent resistance to vibration and shock

Limitations and Considerations

1. Sensitive to improper installation

2. Risk of damaging the flare during assembly

3. Not ideal for soft tubing materials like aluminum

4. Requires proper space and alignment during installation

Installation Best Practices

1. Tube Preparation and Flaring

Ensure clean, square cuts and use proper flaring tools to create uniform flares.

2. Correct Torque Application

Follow manufacturer torque recommendations to avoid over- or under-tightening.

3. Alignment Tips

Align tubing carefully to avoid side loading, which can cause leaks.

4. Common Mistakes to Avoid

➡️ Mixing flare standards

➡️ Reusing damaged flares

➡️ Over-tightening fittings

Maintenance and Inspection Tips

1. Signs of Wear or Damage

Look for cracks, deformation, or leakage at the flare joint.

2. When to Replace Fittings

Replace fittings if the flare surface is damaged or sealing performance declines.

3. Preventing Leaks Over Time

Regular inspections and correct torque help maintain system integrity.

4. Recommended Inspection Intervals

Inspect fittings during routine hydraulic system maintenance or shutdowns.

Flare to Flare vs Other Hydraulic Fittings

The choice depends on pressure, vibration, maintenance needs, and industry standards.

1. ORFS Fittings

Offer superior leak prevention with O-rings but require seal replacement.

2. Compression Fittings

Easy to install but may not handle high vibration as well.

3. NPT Fittings

Use tapered threads and sealants; more prone to leaks than flare fittings.

How to Choose the Right Flare to Flare Fitting

1. Match pressure and temperature ratings

2. Select appropriate materials for the environment

3. Ensure correct size and thread compatibility

4. Verify compliance with industry standards and certifications

Safety Considerations

Hydraulic systems operate under extreme pressure and pose serious risks if fittings fail.

➡️ Follow proper installation procedures

➡️ Use personal protective equipment during maintenance

➡️ Always use certified, high-quality components

Frequently Asked Questions (FAQs)

Are flare to flare fittings reusable?

Yes, as long as the flare and fitting surfaces are undamaged.

Can flare fittings be used with hydraulic hose?

They are primarily designed for rigid tubing, not flexible hose.

What causes flare fitting leaks?

Improper torque, misalignment, damaged flares, or incompatible standards.

Are flare fittings interchangeable across brands?

They can be, but compatibility depends on standards, tolerances, and quality.

Conclusion

Flare to flare hydraulic fittings are a proven solution for creating strong, leak-resistant connections in high-pressure fluid power systems. By understanding how they work, their advantages and limitations, and following proper installation and maintenance practices, you can significantly improve hydraulic system reliability and safety.

Selecting the correct flare standard, material, and size, and installing it correctly, will ensure long-term performance and minimize downtime in demanding hydraulic applications.

Post time: Jan-14-2026