Flanges are essential components in piping systems, serving as the connecting interface between pipes, valves, pumps, and other equipment. They allow for easy assembly and disassembly, providing access for inspection, maintenance, and modification. A properly selected flange ensures a leak-free, strong, and durable connection in high-pressure or corrosive environments.

Because piping systems are used worldwide across industries such as oil and gas, petrochemical, power generation, and water treatment, standardization is critical. International standards define dimensions, materials, pressure ratings, and testing methods, ensuring compatibility, safety, and interchangeability between manufacturers and systems.

In this article, we’ll compare three of the most widely used flange standards globally:

➡️ JIS (Japanese Industrial Standard)

➡️ ANSI (American National Standards Institute)

➡️ DIN (Deutsches Institut für Normung)

Each of these standards defines specific requirements for flange dimensions, pressure ratings, and materials. Understanding their differences helps engineers and buyers choose the right flange for their applications.

Understanding the Different Flange Standards

JIS Flange (Japanese Industrial Standard)

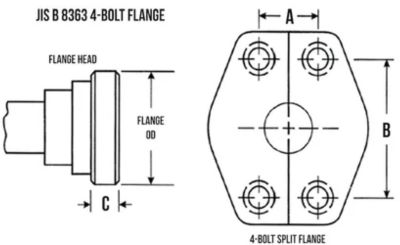

The JIS B2220 standard governs flanges in Japan and other regions that follow Japanese industrial practices. JIS flanges are known for their precise dimensions and quality manufacturing.

Commonly Used Materials:

➡️ Carbon steel (SS400, S10C, S45C)

➡️ Stainless steel (SUS304, SUS316)

➡️ Alloy steel (SF440A, SF440B)

Pressure Ratings:

JIS flanges are categorized by “K” ratings, representing pressure resistance in kilograms per square centimeter (kg/cm²):

5K, 10K, 16K, 20K, and 30K

Applications:

These flanges are widely used in Japan, Korea, and other Asia-Pacific regions, particularly in waterworks, shipbuilding, and general industrial systems.

ANSI Flange (American National Standards Institute)

ANSI flanges are based on the ASME B16.5 standard (developed by the American Society of Mechanical Engineers). They are among the most commonly used flanges in North America and in international projects that follow ASME piping codes.

Pressure Classes:

ANSI flanges are categorized by “Class” ratings:

Class 150, 300, 600, 900, 1500, and 2500

Each class corresponds to a maximum allowable pressure at a specific temperature.

Applications:

ANSI flanges are standard in the United States, Canada, and international projects involving ASME standards, especially in oil and gas, chemical processing, and power plants.

DIN Flange (Deutsches Institut für Normung)

DIN flanges follow the DIN EN 1092-1 standard, which is widely recognized across Europe and other regions adhering to European Union (EU) standards.

Pressure Ratings:

DIN flanges use the “PN” designation, which stands for “Pressure Nominal.” Common ratings include:

PN 6, PN 10, PN 16, PN 25, and PN 40.

Applications:

DIN flanges are popular in European industries, automotive, pharmaceutical, and manufacturing sectors where EU compliance is mandatory.

Key Differences Between JIS, ANSI, and DIN Flanges

Dimensional Differences

One of the most significant distinctions among these standards is in dimensions—including bolt hole patterns, flange thickness, and outer diameters.

For example, a 4-inch JIS 10K flange will not align with a 4-inch ANSI Class 150 flange or a DN100 PN16 flange because the bolt circle diameters and number of bolts differ.

|

Flange Type |

Nominal Size |

Bolt Holes |

Bolt Circle (mm) |

Pressure Rating |

|

JIS 10K |

100A (4”) |

8 |

175 |

10K |

|

ANSI Class 150 |

4” |

8 |

190 |

150 psi |

|

DIN PN16 |

DN100 |

8 |

180 |

16 bar |

Because of these variations, flanges from different standards are not interchangeable without adapters or modifications.

Pressure Rating Systems

Each standard uses its own system to define pressure capacity:

➡️ JIS: “K” (kilogram per square centimeter)

➡️ ANSI: “Class” (based on psi at reference temperature)

➡️ DIN: “PN” (bar rating)

While conversion tables exist, they don’t translate perfectly because pressure-temperature relationships differ. For instance, a JIS 10K flange may handle similar pressures to an ANSI Class 150 flange, but they are dimensionally incompatible.

Material Specifications

Each standard also specifies materials differently:

1. JIS: Japanese grades (e.g., SS400, SUS304)

2. ANSI: ASTM or ASME grades (e.g., A105, A182 F304)

3. DIN: EN material grades (e.g., C22.8, 1.4301)

While similar materials exist across standards, engineers must confirm mechanical properties, chemical composition, and corrosion resistance before substitution.

Application Regions and Industrial Usage

|

Standard |

Primary Region |

Typical Industries |

|

JIS |

Japan, Korea, Asia-Pacific |

Shipbuilding, Waterworks, General Industry |

|

ANSI |

North America, Global ASME Projects |

Oil & Gas, Power, Petrochemical |

|

DIN |

Europe, Middle East, Africa |

Manufacturing, Food & Beverage, Pharmaceuticals |

Global projects sometimes require dual standard flanges or conversion adapters to connect systems built to different standards.

Conversion and Compatibility

Mixing JIS, ANSI, and DIN flanges directly is not recommended. Differences in bolt hole alignment, thickness, and sealing faces can lead to leakage, mechanical failure, or safety hazards.

If integration between systems is unavoidable, conversion flanges or adapters can be used to bridge standards. However, engineers must ensure proper sealing, pressure rating compatibility, and compliance with safety codes.

Choosing the Right Flange Standard for Your Project

Selecting the right flange standard depends on several key factors:

1. Location: Follow the standard common to the project’s region (e.g., JIS for Japan, DIN for Europe).

2. System Design: Match existing components and equipment standards.

3. Pressure & Temperature: Ensure the flange rating suits operational conditions.

4. Regulatory Compliance: Follow industry and safety standards (ASME, ISO, PED, etc.).

To prevent costly errors, always verify the flange specification during design, procurement, and installation stages, and consult relevant engineering codes.

FAQs

1. Can I use a JIS flange with an ANSI system?

No. Although some sizes appear similar, their bolt hole patterns and dimensions differ, making them incompatible without adapters.

2. Which flange standard is most common worldwide?

The ANSI/ASME standard is the most widely recognized globally, but JIS and DIN flanges remain dominant in their respective regions.

3. What’s the easiest way to identify a flange standard in the field?

Check the markings on the flange face or rim, most include size, pressure rating, and standard (e.g., “JIS 10K 100A” or “ANSI 150 4”).

Conclusion

While JIS, ANSI, and DIN flanges all serve the same purpose, they differ in dimensions, pressure ratings, material standards, and regional usage. Understanding these distinctions is crucial for ensuring system compatibility, safety, and performance.

When planning your piping project, verify flange standards early in the design and purchasing process. Proper selection avoids mismatches, prevents leaks, and ensures long-term reliability.

Post time: Oct-24-2025