When designing or maintaining a fluid or gas system, ferrule connections are among the most important components to get right. These small but critical parts ensure leak-proof seals, maintain system integrity, and provide long-term reliability, especially in industries where safety, precision, and performance are non-negotiable.

Choosing the right ferrule type isn’t just a matter of preference. It affects operational safety, installation time, maintenance costs, and system performance under pressure and vibration. In this guide, we’ll break down the differences between single ferrule and double ferrule fittings so you can confidently select the right option for your application.

You’ll learn how each ferrule type works, their advantages and limitations, key performance differences, and when to choose one over the other.

What Are Ferrule Connections?

Ferrule connections are mechanical compression fittings designed to create a secure, leak-tight seal between tubing and system components. A ferrule is a small ring, usually metallic, that compresses onto the tube when the nut is tightened.

This compression creates two critical functions:

1. A mechanical grip that holds the tube in place

2. A gas- or liquid-tight seal that prevents leaks

Ferrule fittings are widely used in:

➡️ Instrumentation and measurement systems

➡️ Hydraulic equipment

➡️ Chemical processing setups

➡️ Oil & gas production and refining

➡️ Laboratory and analytical equipment

Whenever a system requires precision, reliability, and clean, leak-free connections, ferrules are the industry standard.

How Ferrule Fittings Work

The working principle of a ferrule connection is based on axial compression. When the nut is tightened:

1. The nut advances forward.

2. The ferrule(s) slide and compress against the tubing and the fitting body.

3. The compression creates both the seal and the grip.

Key components include:

➡️ Nut – applies axial force

➡️ Ferrule(s) – create the seal/grip

➡️ Fitting body – receives the tube and ferrules

Proper installation is essential. Under-tightening can lead to leaks, while over-tightening may damage the tubing or ferrules. Following manufacturer instructions, typically torque guidelines or “turns from finger tight”, ensures optimal performance.

Single Ferrule Connections

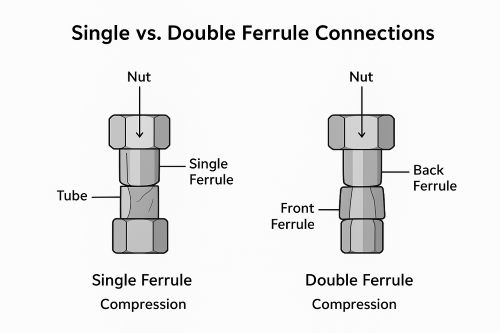

A single ferrule fitting uses one compression ring that performs both sealing and gripping functions. As the nut tightens, the ferrule deforms to bite into the tube surface while simultaneously sealing against the tube and the fitting body.

Advantages of Single Ferrule Connections

1. Simpler design: Fewer parts mean easier handling and assembly.

2. Lower cost: Typically more affordable than double-ferrule systems.

3. Easier installation: Ideal for technicians seeking quick, straightforward assembly.

4. Ideal for softer tubing: Performs well with copper, aluminum, and plastic tubes.

Limitations

1. Weaker tube grip: Less mechanical holding force compared to double ferrule.

2. Reduced vibration resistance: Not the best option for systems with frequent movement.

3. Not suited for high-pressure systems: Best for low- to medium-pressure applications.

Double Ferrule Connections

A double ferrule fitting uses two rings:

➡️ Front ferrule – creates the primary seal

➡️ Back ferrule – clamps the tube, distributing force and improving grip

This division of responsibilities enables a more secure, high-performance connection.

Advantages of Double Ferrule Connections

1. Superior tube grip: Back ferrule delivers strong mechanical holding power.

2. Excellent vibration resistance: Ideal for rotating equipment or mobile machinery.

3. Enhanced leak protection: More reliable sealing in critical systems.

4. High pressure capability: Perfect for hydraulic, chemical, and instrumentation environments.

Limitations

1. Higher cost: More parts and tighter tolerances increase the price.

2. Requires precise installation: Proper alignment and torque are essential for performance.

3. May be overkill: Not necessary for general-purpose or low-pressure uses.

Comparison Table: Single vs. Double Ferrule Connections

|

Feature |

Single Ferrule |

Double Ferrule |

|

Number of Ferrules |

1 (combined seal + grip) |

2 (front ferrule for seal, back ferrule for grip) |

|

Pressure Capability |

Moderate |

High |

|

Vibration Resistance |

Limited |

Excellent |

|

Installation Complexity |

Simple |

Requires more precision |

|

Cost |

Lower |

Higher |

|

Grip Strength |

Adequate for general use |

Strong, ideal for critical systems |

|

Best For |

General-purpose, low/medium pressure |

High-pressure, vibration-heavy, critical applications |

|

Tubing Compatibility |

Works well with softer tubing materials |

Works well with harder metals, high-performance alloys |

Visual Diagram: Single vs. Double Ferrule Function (ASCII)

Single Ferrule Fitting (One Ferrule Handles Seal + Grip)

The single ferrule compresses once, creating the seal and mechanical grip in the same action.

Double Ferrule Fitting (Two Ferrules With Separate Roles)

➡️ Front ferrule: Bites into the tube to form the seal

➡️ Back ferrule: Clamps the tube for superior grip and vibration resistance

When to Choose Single Ferrule Connections

Choose single ferrule fittings when your system involves:

1. Low- to medium-pressure conditions

2. General-purpose operations

3. Minimal vibration exposure

4. Cost-sensitive applications

5. Softer tubing materials

When to Choose Double Ferrule Connections

Double ferrule fittings are the best choice for:

1. High-pressure or mission-critical systems

2. Environments with vibration, shocks, or thermal cycling

3. Applications demanding high leak integrity

4. Instrumentation, oil & gas, chemical plants, and industrial processes

Common Misconceptions

“Double ferrule is always better.”

Not necessarily. If your system doesn’t require high pressure or vibration resistance, single ferrule fittings may be the optimal and more economical choice.

“Single ferrule fittings cannot handle pressure.”

They can handle moderate pressure when matched with the correct tubing and installation procedures.

“Installation is the same for both types.”

Small differences in installation technique can significantly impact performance, especially with double ferrule designs.

Installation Tips for Optimal Performance

1. Follow manufacturer guidelines for torque or “turns from finger-tight.”

2. Prepare tubing properly: cut square, deburr, and clean thoroughly.

3. Use compatible materials: match ferrule hardness and tubing alloy to avoid deformation or leakage.

4. Perform re-tightening checks in systems with vibration or thermal fluctuations.

Good installation is often the difference between years of leak-free service and early failure.

Conclusion

Single and double ferrule connections both play essential roles in fluid and gas systems, but they’re designed for different performance requirements.

➡️ Choose single ferrule for simplicity, cost savings, and moderate pressure applications.

➡️ Choose double ferrule for high performance, high pressure, and high vibration environments.

Selecting the right ferrule type ensures safety, reliability, and long-term cost efficiency.

For best results, always refer to manufacturer specifications or consult an engineering expert to ensure the optimal choice for your system.

Post time: Nov-18-2025