Hydraulic fittings are essential components in fluid power systems, enabling the secure and leak-free transfer of fluids under high pressure. Choosing the right fitting standard is critical to system performance, longevity, and safety.

Two widely used standards are DIN 2353 and SAE fittings. Each has its own design principles, thread types, and sealing methods. Understanding their differences helps engineers and technicians make informed decisions during system design and maintenance.

In this guide, we’ll explore the technical differences, applications, pros and cons of DIN 2353 vs SAE hydraulic fittings.

What Are Hydraulic Fitting Standards?

Hydraulic fitting standards ensure that components from different manufacturers are compatible and perform safely under defined conditions. These standards cover dimensions, thread types, pressure ratings, and sealing methods.

Common Hydraulic Standards:

-

SAE (Society of Automotive Engineers)

-

DIN (Deutsches Institut für Normung)

-

ISO (International Organization for Standardization)

-

JIC (Joint Industry Council)

This article focuses specifically on the DIN 2353 (ISO 8434-1) and SAE (e.g., J514, J1453) standards.

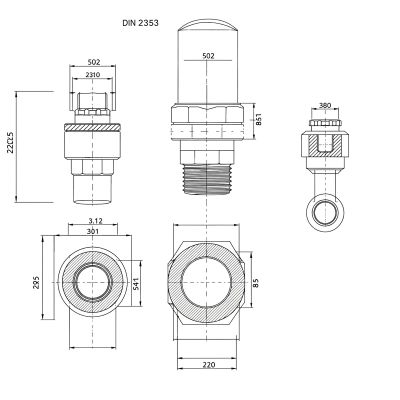

Overview of DIN 2353 Fittings

DIN 2353 fittings are governed by DIN EN ISO 8434-1, a standard widely adopted across Europe and many global markets. These fittings use metric sizing and a metal-to-metal seal for high-pressure performance.

Key Features:

1. Components: Cutting ring, nut, and fitting body

2. Sealing: Compression of the cutting ring into the tube creates a secure metal seal

3. Pressure Series:

-

LL (Light-Light) for low pressure

-

L (Light) for medium pressure

-

S (Heavy) for high pressure

4. Materials: Typically steel, stainless steel, or brass

These fittings are ideal for environments where high vibration, temperature changes, and mechanical stress are common.

Overview of SAE Fittings

SAE fittings are commonly used in North America, with standards such as SAE J514 and SAE J1453 defining different fitting types. These fittings use inch-based (imperial) sizing and rely on a variety of sealing methods.

Common SAE Fitting Types:

-

SAE 37° Flare (JIC)

-

SAE O-Ring Boss (ORB)

-

SAE O-Ring Face Seal (ORFS)

These fittings are popular due to their widespread availability and compatibility with many American-made systems.

Key Differences Between DIN 2353 and SAE Fittings

|

Feature |

DIN 2353 |

SAE |

|

Sizing System |

Metric |

Imperial (inch) |

|

Sealing Mechanism |

Metal-to-metal (cutting ring) |

O-ring, flare, or mechanical seal |

|

Thread Type |

Metric threads |

Unified National threads |

|

Pressure Range |

LL, L, S series for flexibility |

Varies by fitting type (ORB, JIC, etc.) |

|

Use Regions |

Europe, global OEMs |

North America |

|

Reusability |

High (metal seal is durable) |

Varies depending on seal type |

Choosing the Right Standard for Your Application

When deciding between DIN 2353 and SAE fittings, consider the following factors:

-

System Pressure: Choose a fitting rated for your operating pressure.

-

Vibration & Shock Loads: DIN 2353 excels in high-vibration conditions.

-

Corrosion Resistance: Material choice matters more than the standard.

-

Geographic Region: SAE for North America; DIN 2353 for Europe or global compatibility.

-

Tooling and Inventory: Consider what’s already available in your workshop or supply chain.

Industry Preferences

-

DIN 2353: Industrial hydraulics, machine tools, European OEMs

-

SAE: Mobile equipment, agriculture, U.S.-based systems

Interchangeability and Compatibility

Generally, DIN 2353 and SAE fittings are not interchangeable due to different thread profiles and sealing methods.

Key Considerations:

-

Thread compatibility: Mismatched threads can lead to leaks or system failure.

-

Seal compatibility: O-rings vs. cutting rings have different behaviors under pressure.

-

Adapters: Available for connecting SAE and DIN systems, but introduce potential leak points and pressure drops.

Installation and Maintenance Considerations

Proper installation is essential for leak-free performance, regardless of standard.

DIN 2353:

-

Requires clean, properly cut tubing

-

Cutting ring must bite securely into the tube

-

Use proper torque values and assembly tools

SAE:

-

O-rings must be inspected and lubricated

-

Avoid over-torquing which can damage seals

-

Follow manufacturer torque specs

Pros and Cons Summary Table

|

Standard |

Pros |

Cons |

|

DIN 2353 |

Precise sealing, wide pressure range, excellent vibration resistance |

May require metric tools, less common in North America |

|

SAE |

Widely available in the U.S., multiple sealing options |

Thread compatibility issues, variable sealing reliability |

Conclusion

DIN 2353 and SAE fittings are both excellent choices—when used in the right context. By understanding their technical specifications, sealing mechanisms, and regional applications, engineers can choose the best solution for system reliability and safety.

Need help selecting the right fitting? Explore our full range of DIN and SAE fittings to find the perfect match for your hydraulic system

-

Download our detailed comparison charts and catalogs for easy reference

-

Contact our support team for personalized sizing and compatibility assistance

Stay informed! Contact us for more hydraulic insights and expert tips!

Post time: May-06-2025