Hydraulic systems rely on precise, leak-free connections to operate safely and efficiently. One of the most common causes of hydraulic leaks and fitting failures is the use of incorrect or mismatched thread types. Among the most frequently confused standards are NPT and BSP hydraulic fittings.

At first glance, NPT and BSP threads can look very similar. In fact, they may even screw together a few turns, which leads many technicians to assume they are compatible. However, these two thread standards are fundamentally different in design, sealing method, and application. Using the wrong one can result in leaks, damaged components, pressure loss, or even catastrophic system failure.

This guide explains the difference between NPT (National Pipe Taper) and BSP (British Standard Pipe) hydraulic fittings, how to identify them, and how to choose the right option for your hydraulic system.

What Are Hydraulic Thread Standards?

Thread standards define how fittings connect pipes, hoses, valves, and other hydraulic components. These standards ensure:

1. Proper mechanical strength

2. Reliable sealing under pressure

3. Interchangeability within the same system

4. Safety and performance consistency

Different regions of the world developed their own standards, which is why multiple thread types exist today. The most important distinction among hydraulic threads is whether they are tapered or parallel, and how they seal.

Some threads seal by metal-to-metal interference, while others rely on elastomeric seals such as O-rings or bonded washers. Understanding this difference is critical when comparing NPT and BSP fittings.

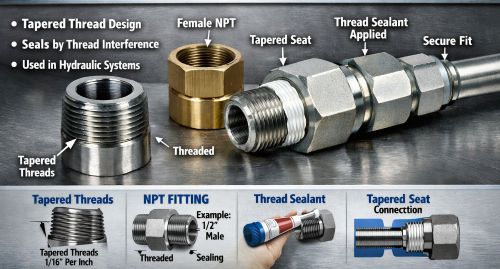

What Is NPT (National Pipe Taper)?

NPT stands for National Pipe Taper. It is a U.S. standard governed by ANSI/ASME B1.20.1 and is widely used in North America.

NPT fittings are common in:

➡️ Hydraulic systems

➡️ Pneumatic systems

➡️ Industrial piping

➡️ Oil and gas equipment

Key Characteristics of NPT Threads

1. Thread type: Tapered

2. Thread angle: 60 degrees

3. Taper rate: 1 in 16 (¾ inch per foot)

4. Sealing method: Thread interference

As NPT fittings are tightened, the tapered male and female threads wedge together. This metal-to-metal contact creates a seal, but it is not sufficient on its own. Thread sealant is almost always required.

Common Sealing Methods for NPT

➡️ PTFE (Teflon) tape

➡️ Liquid thread sealant or pipe dope

These sealants fill microscopic gaps in the threads and prevent leakage.

Typical NPT Applications

➡️ Low to high-pressure hydraulics

➡️ Compressed air systems

➡️ Fuel and lubrication lines

What Is BSP (British Standard Pipe)?

BSP stands for British Standard Pipe. It originated in the United Kingdom and is governed by BS and ISO standards. BSP threads are widely used in:

➡️ Europe

➡️ Asia

➡️ Australia

➡️ Africa

Two Types of BSP Threads

BSP comes in two distinct forms, which is a major source of confusion:

1. BSPP – British Standard Pipe Parallel

2. BSPT – British Standard Pipe Tapered

BSP Thread Characteristics

1. Thread angle: 55 degrees

2. Thread form: Whitworth profile (rounded crests and roots)

This 55-degree angle is one of the easiest ways to distinguish BSP from NPT.

Visual Thread Profile Comparison

Thread Angle Difference

NPT Thread Profile (60°)

/\ /\ /\

/ \ / \ / \

/ \__/ \__/ \__

BSP Thread Profile (55°)

/\ /\ /\

/ \ / \ / \

/ \____ \____ \__

Tapered vs. Parallel

Tapered Thread (NPT / BSPT)

|\

| \

| \

| \

Parallel Thread (BSPP)

| |

| |

| |

| |

Key Differences Between NPT and BSP Threads

|

Feature |

NPT |

BSP |

|

Full name |

National Pipe Taper |

British Standard Pipe |

|

Governing standard |

ANSI / ASME |

BS / ISO |

|

Thread angle |

60° |

55° |

|

Thread type |

Tapered only |

Parallel (BSPP) or Tapered (BSPT) |

|

Sealing method |

Thread interference + sealant |

O-ring/washer (BSPP) or thread sealant (BSPT) |

|

Common regions |

North America |

Europe, Asia, Australia |

|

Interchangeable |

❌ No |

❌ No |

Why NPT and BSP Are Not Interchangeable

Although NPT and BSPT threads are both tapered, they must never be mixed. Here’s why:

➡️ Different thread angles (60° vs. 55°)

➡️ Different pitch and depth

➡️ Different crest and root geometry

What Happens If You Mix Them?

1. Threads may engage only a few turns

2. Poor surface contact leads to leaks

3. High risk of cross-threading

4. Permanent damage to ports and fittings

5. Failure under pressure

Even if a connection appears tight, it may fail suddenly once the system is pressurized.

How to Identify NPT vs. BSP Threads

1. Check the Thread Angle

➡️ 60° = likely NPT

➡️ 55° = likely BSP

Thread gauges make this easy and accurate.

2. Measure Taper

➡️ Use calipers to measure diameter at multiple points

➡️ Tapered threads will get wider toward the base

➡️ Parallel threads maintain the same diameter

3. Inspect the Sealing Surface

➡️ Flat face or O-ring groove → BSPP

➡️ No sealing face → likely NPT or BSPT

4. Know the Equipment Origin

➡️ U.S. machinery → often NPT

➡️ European or Asian machinery → often BSP

Choosing the Right Hydraulic Fitting

When selecting between NPT and BSP fittings, consider the following:

System Requirements

1. Operating pressure

2. Temperature range

3. Vibration levels

Compatibility

1. Match the thread standard exactly

2. Never “force” a fitting to work

Sealing Reliability

1. BSPP with O-ring offers excellent leak resistance

2. NPT relies heavily on proper sealant application

Industry Best Practice

Modern hydraulic systems increasingly favor O-ring-based sealing (such as BSPP) because it provides:

➡️ Better repeatability

➡️ Less dependence on installer technique

➡️ Improved reliability under high pressure

Frequently Asked Questions

1. Is BSP the same as NPT?

No. They have different thread angles, profiles, and sealing methods. They are not interchangeable.

2. Can I use adapters between BSP and NPT?

Yes. Properly designed adapters are the only safe way to connect BSP and NPT components.

3. Which is better for high-pressure hydraulics?

BSPP with an O-ring or bonded seal generally offers superior leak prevention compared to NPT.

4. Do BSP fittings always need O-rings?

BSPP fittings do. BSPT fittings typically use thread sealant.

5. Why do BSP and NPT sometimes appear to fit?

The taper and pitch are similar enough to allow partial engagement—but not enough for a safe seal.

Conclusion

Understanding the difference between NPT and BSP hydraulic fittings is essential for anyone working with hydraulic or fluid power systems. While they may look similar, their differences in thread angle, sealing method, and design make them incompatible without proper adapters.

Using the correct fitting:

➡️ Prevents leaks

➡️ Protects equipment

➡️ Improves system safety

➡️ Reduces downtime and maintenance costs

Before installing any hydraulic fitting, always verify the thread type, sealing method, and standard. When in doubt, consult technical documentation or a qualified hydraulic supplier. A small mistake at the fitting level can lead to big problems down the line.

Post time: Feb-11-2026